Double Flanged Butterfly Valve, B148 C95800, 2 IN, 300 LB

Key Specifications / Features

As a specialized fabricator of double-offset butterfly valves, we offer high-performance solutions designed to meet API 609 and EN 593 standards. Our 2-inch, Class 300 LB valves are crafted from durable ASTM B148 C95800 materials, providing excellent corrosion resistance. Equipped with a 17-4PH stem and an RPTFE seat, these double flanged valves ensure reliable sealing and optimal performance in various industrial applications. Engineered for long-lasting durability, our butterfly valves are ideal for demanding environments, offering efficiency and precision flow control.

Request a quote

Detail Information

On this page

EN 593 High-Performance Butterfly Valve, Double Offset, RPTFE Seat, 2 Inch/DN50, 300 LB, Gear Operation.

Design Standard: EN 593, API 609 Category B

Structure: Double Offset, Double Eccentric

Nominal Size: 2 Inch, DN50

Nominal Class: Class 300 LB, PN50

Seat Type: Soft Seat

Operation: Gear

Body Material: ASTM B148 C95800, ASTM A890 4A, ASTM A890 5A, ASTM A351 CF8M, ASTM A216 WCB, ASTM A351 CF8, Titanium.

Seat: RPTFE, PPL

End Connection: Double Flanged

Face to Face: API 609, EN 593

Test and Inspection: API 598, API 609

Trim Material: ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium

2. Reduced torque for smoother operation.

3. Replaceable seat for easy maintenance.

4. Reliable tight sealing performance.

5. Superior control characteristics.

6. Bi-directional sealing under full pressure.

7. Fire-safe seat option available.

Valve Description

1862138 High-Performance Butterfly ValveDesign Standard: EN 593, API 609 Category B

Structure: Double Offset, Double Eccentric

Nominal Size: 2 Inch, DN50

Nominal Class: Class 300 LB, PN50

Seat Type: Soft Seat

Operation: Gear

Body Material: ASTM B148 C95800, ASTM A890 4A, ASTM A890 5A, ASTM A351 CF8M, ASTM A216 WCB, ASTM A351 CF8, Titanium.

Seat: RPTFE, PPL

End Connection: Double Flanged

Face to Face: API 609, EN 593

Test and Inspection: API 598, API 609

Trim Material: ASTM A351 CF8, ASTM A351 CF8M, ASTM A890 4A, ASTM A890 5A, ASTM B148 C95800, Titanium

Key Features

1. Long lifespan for high-frequency operation (up to a million cycles).2. Reduced torque for smoother operation.

3. Replaceable seat for easy maintenance.

4. Reliable tight sealing performance.

5. Superior control characteristics.

6. Bi-directional sealing under full pressure.

7. Fire-safe seat option available.

Product Range

| Body Material: | Carbon Steel, Stainless Steel, Duplex Steel, Aluminum Bronze, Titanium |

| Pressure Range: | Class 150 LB - 300 LB |

| Operation: | Manual (lever, gear), Pneumatic Actuator, Motor Actuator |

| Normal Diameter: | 1/2 Inch - 48 Inch (DN15 - DN1200) |

| Working Temperature: | -26°C - +120°C (180°C for PPL seat) |

| End Connection: | Wafer, Lug, Flanged |

| Operation Types: | Lever, gear, and pneumatic actuator options available. |

| Bosseal Valve advantages: | Zero leakage, low torque, extended service life, low emissions, bi-directional flow, and fire-safe design. |

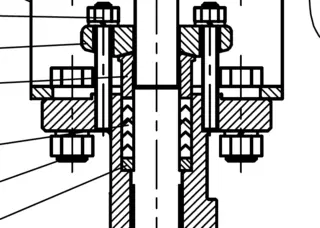

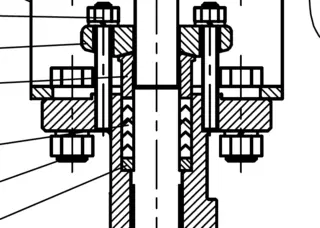

Low Emission and Anti-Blowout Stem Design

The packing is made from pre-compressed flexible graphite rings, with precisely controlled stem and stuffing box surface roughness to ensure lower torque and enhanced sealing performance. A live-loaded gland flange allows for easy adjustment of packing compression. The space ring and gland design effectively prevent stem blowout, ensuring safety and reliability.

-320x288.webp)