Bellows Control Valve: Precision Flow Regulation for Industrial Applications

Introduction

In modern industrial processes, accurate and reliable control of fluid flow is essential for efficiency, safety, and product quality. Among the various valve types used for flow regulation, bellows control valves have emerged as a critical solution for high-precision applications. These specialized valves combine advanced sealing technology with pressure-balancing designs, enabling accurate control in environments where conventional valves may struggle.

Bellows control valves are widely used in industries such as chemical processing, petroleum refining, pharmaceuticals, food production, metallurgy, and power generation. They are particularly valued for their ability to handle hazardous or high-purity fluids, maintain tight control under fluctuating pressures, and provide long-term reliability with minimal maintenance.

What Is a Bellows Control Valve?

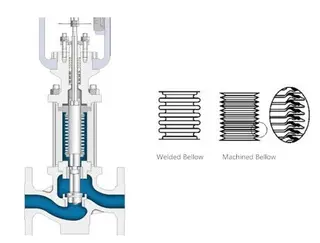

A bellows control valve is a type of valve specifically designed for precision flow regulation in fluid systems. Its defining feature is the bellows element, a flexible, accordion-like structure typically made of metal or elastomeric materials. This bellows acts as both a sealing mechanism and a pressure-balancing component, allowing the valve to maintain accurate flow control while minimizing the impact of pressure fluctuations.

The bellows element expands and contracts in response to changes in pressure or actuator movement. This flexibility allows the valve plug to modulate fluid flow with high precision, making bellows control valves ideal for sensitive processes that require stable, repeatable control. Unlike traditional packing-sealed valves, which may experience leakage over time, bellows valves provide a hermetic seal, ensuring safety and environmental compliance.

Key Components of Bellows Control Valves

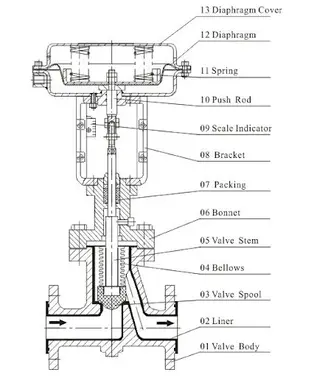

Bellows control valves consist of several essential components, each contributing to their performance, durability, and versatility:

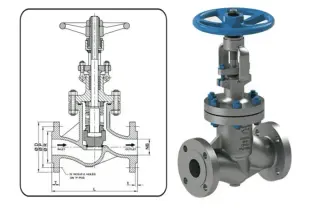

Valve Body

The main housing of the valve that connects to the piping system and contains internal components.

Constructed from corrosion-resistant or high-strength materials to handle extreme pressures and temperatures.

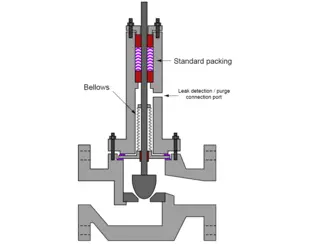

Bellows Element

The flexible, accordion-like structure that serves as a hermetic seal.

Prevents leakage and isolates the valve stem from the fluid, improving safety and reducing maintenance.

Valve Stem

Connects the actuator to the valve plug.

Transmits motion accurately to regulate flow through the valve seat.

Valve Plug

Controls fluid flow by moving in and out of the valve seat.

Precision-machined for smooth operation and accurate throttling.

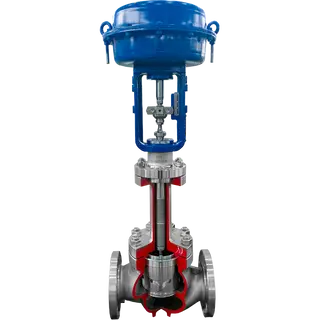

Actuator

Provides the motive force for valve operation, which may be pneumatic, electric, or hydraulic.

Ensures rapid and precise response to control signals, maintaining system stability.

Bonnet

Encloses the bellows assembly and provides a secondary seal.

Protects internal components from external contamination and mechanical damage.

These components work in harmony to ensure accurate flow control, leak-tight sealing, and reliable operation in demanding industrial environments.

How Bellows Control Valves Work

Bellows control valves operate by translating actuator movement into precise valve plug motion. The bellows element isolates the valve stem from the fluid medium, maintaining a hermetic seal that prevents fugitive emissions and leakage.

In a typical pneumatic bellows control valve, compressed air is used to actuate the valve. The actuator responds rapidly to control signals, moving the stem and plug to modulate flow. The bellows expands or contracts with stem movement, absorbing mechanical stress and pressure fluctuations while maintaining a perfect seal.

This design allows the valve to achieve:

High control accuracy: ±1% or better, depending on system calibration.

Zero or near-zero leakage: Critical for toxic, corrosive, or high-purity fluids.

Stable operation under fluctuating pressures: Pressure-balanced design reduces the impact of upstream or downstream pressure changes.

Advantages of Bellows Control Valves

Bellows control valves offer significant advantages over traditional valves, making them highly desirable for precision industrial applications:

1. Enhanced Leak Prevention

The bellows element provides a superior seal compared to conventional packing designs. By creating a hermetic barrier around the valve stem, these valves minimize the risk of fugitive emissions, protect personnel, and reduce environmental contamination. This is particularly important in chemical plants, pharmaceutical production, and other applications handling hazardous media.

2. Improved Control Accuracy

Bellows control valves are pressure-balanced, which allows for precise flow regulation even under varying pressure conditions. The high-precision valve plug design, combined with rapid actuator response, ensures that setpoints are maintained consistently, improving process stability and product quality.

3. Extended Service Life

By absorbing thermal expansion and mechanical stresses, the bellows protects valve components from excessive wear. This results in a longer operational lifespan compared to conventional valves, reducing the frequency of replacements and lowering total ownership costs.

4. Reduced Maintenance Requirements

The hermetic seal eliminates the need for regular packing adjustments and frequent leak inspections. Maintenance is simplified, downtime is minimized, and operational costs are reduced, which is critical in high-throughput or 24/7 industrial processes.

5. Versatility in Harsh Environments

Bellows control valves can be manufactured from a wide range of materials, including stainless steel, nickel-based alloys, and specialty plastics. This allows them to handle corrosive fluids, high temperatures, and high-pressure systems, making them suitable for the most demanding industrial environments.

Applications of Bellows Control Valves

Bellows control valves are used in numerous industries where precise flow control and leak-tight performance are essential. Common applications include:

1. Chemical Industry

In chemical production, bellows control valves regulate the feed of chemicals to reaction vessels, control solvent delivery, and manage the flow of corrosive or toxic substances. Their superior sealing performance reduces the risk of environmental contamination and improves process safety.

2. Petroleum and Refining

Bellows control valves are used in crude oil distillation and refining processes to manage reflux flows, control heating media, and regulate product streams. Their precise control ensures product quality, energy efficiency, and stable operation of complex refinery systems.

3. Pharmaceutical Industry

High-purity fluid handling is critical in pharmaceuticals. Bellows control valves maintain sterility, prevent contamination, and provide precise dosing and flow regulation for liquid medicines, solvents, and other sensitive media.

4. Food and Beverage Industry

In food processing, these valves accurately control the flow of heating or cooling media, ensuring consistent temperatures during cooking, pasteurization, or fermentation processes. Their hygienic design and reliable sealing prevent contamination and maintain food safety standards.

5. Metallurgy and Power Generation

Bellows control valves are also used in metallurgical processes to regulate steam, cooling water, or chemical additives. In power plants, they manage high-temperature fluids, steam turbines, and auxiliary systems with precision.

6. Research and Laboratory Applications

Laboratories and pilot plants often require precise control over reactive or hazardous fluids. Bellows control valves provide leak-free, adjustable flow for experiments, pilot-scale reactions, and testing systems.

Types of Bellows Control Valves

Bellows control valves can be categorized based on actuator type, body design, or pressure/temperature rating:

Pneumatic Bellows Control Valves

Most common in industrial automation.

Fast response, high precision, and suitable for high-frequency operation.

Electric Bellows Control Valves

Ideal for systems with remote monitoring and automated control.

Can be integrated with digital controllers for process optimization.

Hydraulic Bellows Control Valves

Used in heavy-duty applications requiring high force or rapid actuation.

High-Temperature Bellows Valves

Constructed with special alloys to handle steam, hot oil, or molten chemicals.

Corrosion-Resistant Bellows Valves

Designed for acids, alkalis, or other aggressive chemicals using stainless steel or exotic alloys.

Design Considerations of Bellows Control Valves

When selecting a bellows control valve, engineers must consider:

Fluid type: Corrosive, toxic, or high-purity fluids require specialized materials and sealing solutions.

Operating pressure and temperature: Valve body, bellows, and actuator must be rated for the system conditions.

Flow characteristics: Control valves must match the system’s flow coefficient (Cv) for accurate throttling.

Actuation method: Pneumatic, electric, or hydraulic actuation depends on system control requirements.

Maintenance and accessibility: Consider installation space and ease of replacement or inspection.

Proper sizing, material selection, and actuator matching are critical to ensure the valve performs reliably throughout its service life.

Maintenance and Reliability

Bellows control valves are engineered for long-term reliability, but routine inspection is still recommended:

Check for signs of wear or fatigue in the bellows.

Inspect actuators for responsiveness and leakage.

Verify calibration and control accuracy periodically.

Ensure flange connections and fasteners remain secure.

Due to their hermetic seal, maintenance is typically less frequent than conventional packing-sealed valves, significantly reducing downtime in industrial processes.

Future Trends in Bellows Control Valves

The demand for bellows control valves is growing alongside advancements in industrial automation, chemical processing, and energy efficiency. Key trends include:

Integration with smart control systems: Sensors and IoT-enabled actuators provide real-time monitoring and predictive maintenance.

Advanced materials: New alloys and coatings improve resistance to corrosion, high temperatures, and mechanical fatigue.

Miniaturization: Compact valves for precise laboratory or medical applications.

Sustainable design: Reduced fugitive emissions and longer service life contribute to environmentally responsible operations.

As industries increasingly prioritize process precision, environmental compliance, and operational efficiency, bellows control valves will continue to play a central role.

Conclusion

Bellows control valves are essential for modern industrial processes requiring precise flow regulation, leak-free performance, and durability under challenging conditions. Their unique bellows element provides hermetic sealing, pressure balancing, and high accuracy, making them indispensable in chemical processing, petroleum refining, pharmaceuticals, food production, metallurgy, and research applications.

With advantages such as enhanced leak prevention, improved control accuracy, extended service life, and reduced maintenance, bellows control valves offer a reliable solution for demanding industrial environments. As automation, material science, and smart valve technology evolve, these valves will continue to provide the precision, safety, and performance necessary to meet the most stringent process requirements.

Send your message to this supplier

Related Articles from the Supplier

What Are Bellows Seal Globe Valves?

- Jun 26, 2024

How Does the Bellows Seal Globe Valve Work?

- Nov 01, 2024

What Is a Bellows Gate Valve and How Does It Work?

- Jun 27, 2025

What You Need to Know About Bellows Seal Gate Valves

- Jul 25, 2025

Related Articles from China Manufacturers

The Application of Bellows in Control Valves

- Oct 10, 2024

Structural features of bellows globe valves

- Sep 20, 2018

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.mfrsvalve.com/news/bellows-control-valve-precision-flow-regulation-for-industrial-applications.html