Structural Characteristics and Installation of Gate Valves

Detailed Explanation of Gate Valves: Structural Characteristics and Installation Notes

1. Basic concepts of gate valves

Definition of Gate Valves

Gate valves, an important valve widely used in pipelines, mainly play a role in connecting and cutting off media. Although it is not suitable for regulating the flow rate of the medium, its unique opening and closing method - visually displaying the flow rate through the lifting and lowering of the valve stem, such as the opening and closing scale equipped with the elastic seat seal gate valve for firefighting, is a vivid example. Compared to other valves, gate valves have a wider range of applications in terms of pressure, temperature, and diameter.

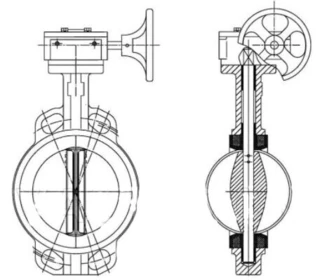

The structure of gate valves

The structure of gate valves varies depending on their internal structure, and can be divided into various types such as wedge-shaped single gate plate, elastic gate plate, double gate plate, and parallel gate plate. Meanwhile, according to the different valve stem supports, gate valves can be divided into rising stem gate valves and hidden stem gate valves.

2. Performance and characteristics of gate valves

Functional characteristics of gate valves

Gate valves have low fluid resistance.

Due to the straight through design of the valve body, the direction of the medium does not change during the flow process, so compared to other types of valves, their fluid resistance is much smaller.

Superior sealing performance:

The sealing performance of gate valves is superior to that of globe valves, and the opening and closing operations are also more effortless.

Wide applicability:

Gate valves are not only suitable for media such as steam and oil, but also for media containing granular solids and high viscosity. In addition, it can also be used as a vent valve and a valve for low vacuum systems.

Dual flow design:

Gate valves have dual flow characteristics and are not limited by the flow direction of the medium. They are very suitable for pipelines where the medium may change its flow direction, and also bring great convenience to installation.

Disadvantages of gate valves

However, gate valves also have some performance disadvantages. In practical applications, it is necessary to select and optimize based on specific usage scenarios and requirements. The design dimensions of gate valves are relatively large. When opening, the valve plate needs to be lifted to the upper part of the valve chamber, while when closing, the valve plate needs to be completely seated in the valve seat. This results in a longer opening and closing stroke of the valve plate, correspondingly extending the opening and closing time.

In addition, during the opening and closing process, there is friction between the valve plate and the valve seat of the gate valve, which may cause scratches on the sealing surface, thereby affecting its sealing performance and service life. In addition, once damaged, repair is relatively difficult.

3. Comparison of various types of gate valves

Characteristics of wedge type single gate valves

The characteristics of wedge type single gate valve include: its structure is simpler compared to elastic gate valve. In high temperature environments, its sealing performance is slightly inferior to that of elastic gate valves or double gate valves. It is especially suitable for high-temperature media that are prone to coking.

Characteristics of elastic gate valves

The elastic gate valve is a variant of wedge type single gate valve, which has better sealing performance in high temperature environments and is less likely to get stuck when the gate is heated. It is especially suitable for the transportation of steam, high-temperature oil products, and oil and gas media, as well as for occasions that require frequent switching. However, it should be noted that it is not suitable for media that are prone to coking.

Characteristics of double gate valves

Double gate valves have excellent sealing performance, even if the inclination angle of the sealing surface and the fit of the valve seat are not precise enough, they can still maintain good sealing effect. When the sealing surface of the gate plate wears out, it is only necessary to replace the metal pads on the top and bottom of the spherical surface. Usually, there is no need to weld or grind the sealing surface, and it can continue to be used.

Double gate valves are also suitable for the transportation of steam, high-temperature oil products, and oil and gas media, and can be used in situations that require frequent opening and closing. However, it should be noted that it is not suitable for media that are prone to coking.

Characteristics of parallel gate valves

In terms of sealing performance, parallel gate valves are slightly inferior to other types of gate valves. This type of gate valve is mainly suitable for media with relatively low temperature and pressure. It is worth mentioning that the machining and maintenance process of the sealing surface of the gate and seat of parallel gate valves is much simpler compared to other gate valves.

4. Installation notes for gate valves

Installation notes and steps

Before installing a parallel gate valve, it is necessary to carefully inspect the key parts such as the valve chamber and sealing surface to ensure that there is no dirt or sand adhering to it, in order to ensure its sealing performance. The bolts connecting each component need to be tightened evenly and tightly to ensure the stability of the connection.

The filling part must be compressed according to the requirements, ensuring both the sealing effect of the filling and the flexible opening of the gate. Before installing forged steel gate valves, users should carefully check the valve model and connection dimensions, and pay special attention to the flow direction of the medium to ensure that it is completely consistent with the requirements of the valve.

During the installation process, sufficient space must be reserved for the valve drive mechanism to facilitate subsequent operation and maintenance. The wiring work of the driving device must be strictly carried out according to the circuit diagram to ensure the correct connection of the circuit. Forged steel gate valves require regular maintenance and upkeep to avoid random collisions and squeezing, in order to prevent adverse effects on their sealing performance.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeevalve.com/structural-characteristics-and-installation-of-gate-valves.html