The Structure and Principle of O-type and V-type Ball Valves

Here are the structure and principle of O-type and V-type ball valves for your reference.

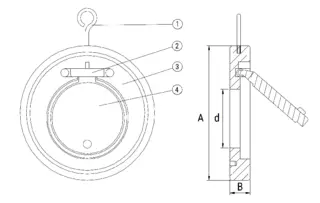

The structure of ball valves

There are many structures for ball valves, but they are basically the same. They are all circular ball cores with opening and closing components, mainly composed of a wide seat, a ball body, a sealing ring, a valve stem, and other driving devices. The valve can be opened and closed by rotating the valve stem 90 degrees. They are used in pipelines to close, distribute, adjust flow rate, and change the flow direction of the medium. The valve seat uses different sealing forms according to different working conditions. The valve body structure includes one-piece, two-piece, and three-piece types.

The structure of O-type ball valves

The valve body of the O-type ball valve is equipped with a ball with a middle through-hole inside. The ball has a through-hole with a diameter equal to the diameter of the pipeline. The ball can rotate in the sealing seat, and there are annular elastic bodies on both sides of the pipeline direction to achieve sealing. By rotating the ball 90 degrees, the direction of the through-hole can be changed to achieve the opening and closing of the ball valve.

The valve core (ball) of the O-type ball valve is spherical, and from a structural perspective, the ball seat is embedded in the valve body side seat during sealing. The relative moving parts are made of self-lubricating materials with extremely low friction coefficients, resulting in low operating torque. In addition, the long-term sealing of the sealing grease makes the operation more flexible. It is generally used for two position adjustment, with a fast opening flow characteristic.

The principle of O-type ball valves

When the O-type ball valve is fully opened, the unobstructed valve is formed on both sides, forming a straight pipe channel and bidirectional sealing. It has the best self-cleaning performance and is suitable for two position cutting occasions with particularly unclean and fiber containing media. The ball core always generates friction with the valve during the opening and closing process, and the sealing between the valve core and the valve seat is achieved through the pre-sealing force of the valve seat pressing against the ball core. However, due to the excellent mechanical and physical properties of the soft seal valve seat, its sealing performance is particularly good.

The structure of V-type ball valves

The core of V-type ball valve has a V-shaped structure, and the valve core is a 114 ball shell with a V-shaped notch. It has a large flow capacity, adjustable range, shear force, and can be closed tightly. It is particularly suitable for working conditions where fluid substances are fibrous. Generally, V-type ball valves are single sealed ball valves. It is not suitable for bidirectional use.

The edge of the valve core is V-shaped, and there is a V-shaped opening on the ball. With the rotation of the ball, the flow rate can be adjusted using the change of the middle opening area, and impurities in the fluid can be cut off to close the control suitable for pulp, mortar, and viscous fluids.

The principle of V-type ball valves

During the rotation of the sphere, the V-type blade of the sphere is tangent to the valve seat, thereby cutting off fibers and solid substances in the fluid. However, general ball valves do not have this function, which can easily cause fiber impurities to get stuck when closing, causing great inconvenience to maintenance and repair. And the valve core of the V-type ball valve will not be stuck by fibers. In addition, due to the use of flange connection, it is easy to disassemble and assemble without the need for special tools, and maintenance is also simple and easy. When the valve is closed, the V-shaped notch and the valve seat generate closed, the effect, which not only has self-cleaning function but also prevents the ball core from getting stuck. The valve body, valve cover, and valve seat adopt a metal point-to-point structure, and a wide rod spring with a low friction coefficient is used. Therefore, the operating torque is small and stable.

Send your message to this supplier

Related Articles from the Supplier

The Structure and Motion Mode of the Gate Valve

- Feb 16, 2023

The Proportion of Valve Continue Growing

- Feb 29, 2016

How to Dig the Potential of Valve Industry

- Aug 28, 2014

Related Articles from China Manufacturers

The Structure and Principle of Ball Valves

- Jun 21, 2022

The Basic Structure and Principle of Cam Locks

- Sep 30, 2023

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeevalve.com/the-structure-and-principle-of-o-type-and-v-type-ball-valves.html