The Structural Characteristics And Applications of Gate Valves

The Structural Characteristics And Applications of Gate Valves

A gate valve is a type of valve that controls fluid flow by moving the gate vertically along the axis of the valve seat, opening or closing the fluid channel like a gate.

1. The structure of gate valves

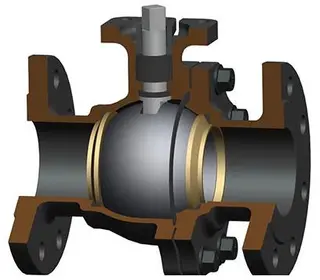

Gate valves are mainly composed of valve body, gate plate, valve stem, valve seat, driving device, packing box, etc.

The valve body is the main body of the valve, providing a channel for medium circulation. It is mostly made of cast iron, cast steel, etc. and needs to withstand system pressure.

The gate is the core opening and closing component, usually a flat or wedge-shaped structure, which is tightly attached to the valve seat to achieve sealing of the fluid channel.

The valve stem connects the gate and the driving device, transmitting the opening and closing force. It is divided into two forms: rising stem gate valves and non-rising stem gate valves according to visibility.

The valve seat is located inside the valve body and forms a sealing surface with the gate plate. The material is often rubber, metal, etc., and it needs to have wear resistance.

The driving device is used to operate the valve stem and drive the gate to move, usually a manual wheel. Larger gate valves use electric actuators, pneumatic devices, etc.

The stuffing box contains packing (such as asbestos rope, polytetrafluoroethylene) and a gland to prevent the medium inside the gate valve from leaking along the valve stem.

2. Characteristics of gate valves

1. Advantages

Low flow resistance: When the gate is fully opened, the medium flows almost in a straight line with low resistance loss, making it suitable for large diameter systems.

Good sealing performance: The gate and valve seat are tightly fitted, and the sealing reliability is high under high pressure (especially for metal sealed gate valves).

Smooth opening and closing: The movement trajectory of the gate is perpendicular to the direction of the fluid, and the impact force during opening and closing is small, suitable for frequent operation (some types).

Bidirectional flow: Most gate valves can block media in both directions, and there is no need to strictly distinguish the flow direction during installation.

2. Disadvantages

Large volume and heavy weight: The structure is complex, especially for large-diameter gate valves, which require high installation space.

Long opening and closing stroke: The valve stem needs to be fully raised or lowered, which takes a long time to operate and is not suitable for emergency cutting scenarios.

The sealing surface is prone to wear: Impurities in the medium may get stuck between the gate and valve seat, causing damage to the sealing surface.

Low temperature prone to condensation: In low-temperature systems, condensation may occur on the surface of the valve body due to temperature differences, requiring additional insulation.

3. The application of gate valves

1. HVAC systems

Water systems: Cut off the main roads of chilled water and cooling water pipelines, or control the inlet and outlet of large air conditioning units and heat ex-changers.

Steam systems: The opening and closing of the main steam pipeline requires the use of a drain valve to prevent the accumulation of condensed water.

Hot water heating systems: it is commonly used for the main valve at the entrance of buildings and units, or for flow control of large radiator branches.

2. Other fields:

Applied in the water supply and drainage system, it is used for controlling the main water supply and drainage pipes, especially suitable for scenarios with large pipe diameters and low flow rates.

Applied in the industrial field, it is used for fluid cutting in industrial pipelines, such as chemical, petroleum, power and other industries.

4. Comparison between visible and hidden poles

1. Structural features

The valve stem of a rising stem gate valve is exposed, and the valve stem moves up and down with the gate during opening and closing. The valve opening can be determined by the height of the valve stem.

The valve stem of the non-rising stem gate valve is not exposed, and the gate is connected to the valve stem through threads. When opening and closing, the valve stem rotates, and the gate rises and falls along the inside of the valve body without significant displacement on the appearance.

2. The form of valve stems

The stem of a rising stem gate valve is a smooth stem with a hand-wheel or drive device at the top, and a packing box seal is required to prevent medium leakage.

The stem of the non-rising stem gate valve has trapezoidal threads that mesh with the internal threads of the gate plate. The threaded portion is immersed in the medium and does not require additional packing sealing (some types).

3. Identification of opening and closing status

A rising stem gate valve can directly observe the height of the valve stem: full lift= drop= open, full drop= drop= closed, height ratio= opening ratio.

The non-rising stem gate valve needs to be judged by the number of rotations of the hand-wheel or the indicator of the driving device, and the opening degree cannot be directly identified from the appearance.

4. Applicable scenarios

Rising stem gate valves are suitable for applications that require visual display of opening (such as systems with frequent manual operations), corrosive media, or outdoor environments that require regular maintenance (additional protection) of the valve stem.

The non-rising stem gate valve is suitable for non-limited scenarios (such as buried pipelines and suspended ceilings), systems with clean media and non-corrosive properties (to avoid threads being blocked by impurities).

5. Maintain demands

The exposed valve stem of a rising stem gate valve is susceptible to environmental influences and requires regular application of lubricating grease. The packing box should be checked for leaks regularly.

The stem thread of the non-rising stem gate valve is internal and requires low maintenance frequency. However, once the thread is damaged, it is difficult to repair and the valve body needs to be disassembled as a whole.

6. Sealing performance

The packing box of the rising stem gate valve has high sealing reliability and is suitable for high-pressure and high viscosity media, but the packing may wear out and need to be replaced after long-term use.

The thread sealing of non-rising stem gate valves relies on medium pressure assistance, and some types have slightly lower sealing performance than exposed stem valves, making them suitable for low-pressure and non-corrosive media.

7. Typical applications

Rising stem gate valves are used on the main pipeline valves and steam pipelines in air conditioning rooms for easy observation of opening and maintenance.

Non-rising stem gate valves are used in buried heating pipelines and concealed water system valves installed in suspended ceilings, which is beneficial for saving space.

8. Selection notes

Select valve body material and sealing form based on system pressure, temperature, and medium characteristics (such as water, steam, corrosive liquids).

Rising stem gate valves are suitable for scenarios that require intuitive monitoring of opening, while non-rising stem gate valves are suitable for situations with limited space or concealed installation.

Metal sealed gate valves are preferred for steam systems, while rubber seals can be used for water systems to enhance sealing performance.

It is recommended to pair large-diameter gate valves (DN ≥ 150) with electric or pneumatic actuators to reduce the difficulty of manual operation.

By understanding the differences in structure and types of gate valves, it is possible to select and apply them more reasonably in HVAC systems, ensuring the stable operation of piping systems.

Send your message to this supplier

Related Articles from the Supplier

The Structure and Motion Mode of the Gate Valve

- Feb 16, 2023

The Proportion of Valve Continue Growing

- Feb 29, 2016

How to Dig the Potential of Valve Industry

- Aug 28, 2014

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.landeevalve.com/the-structural-characteristics-and-applications-of-gate-valves.html