What is Three-Way Ball Valve: Structure, Advantages & Uses

In industrial piping systems, valves play a vital role by precisely controlling the direction, flow rate, and on-off status of fluids. Among the many types of valves, the three-way ball valve stands out as one of the preferred choices in numerous industrial applications due to its unique structural design and excellent performance. This article provides an in-depth discussion of the many advantages, working principles, application scenarios, and characteristics of various types of three-way ball valves, helping you gain a comprehensive understanding of this highly efficient control tool.

Working Principle of Three-Way Ball Valves

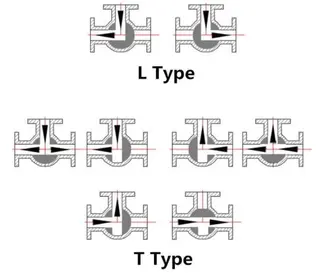

The working principle of a three-way ball valve is based on its uniquely designed valve core. The valve body has three ports, one inlet and two outlets, or two inlets and one outlet. Unlike ordinary valves, the internal valve core of the three-way ball valve connects different outlets depending on its position. For example, when the valve core is located at the lower part, the left and right channels are connected while the bottom outlet is closed; when the valve core is positioned at the upper part, the left and lower channels are connected while the right-side outlet is closed.

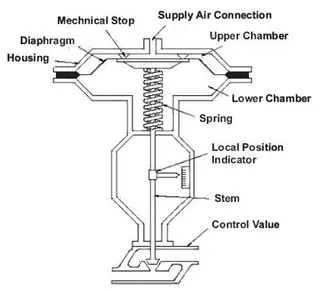

For pneumatic three-way ball valves, the working principle is even more intuitive. When the pneumatic valve is opened, port 2 takes in air while port 4 exhausts air, pushing two pistons to move outward, compressing the springs and rotating the output shaft counterclockwise. When the pneumatic three-way ball valve is closed, in the event of air or power loss, the springs push the two pistons inward, closing the valve and rotating the output shaft clockwise. This pneumatic operation enables the three-way ball valve to achieve fast and accurate switching control, making it suitable for applications requiring frequent operation.

Structure and Advantages of Three-Way Ball Valves

The structural design of the three-way ball valve forms the foundation of its excellent performance. Every detail is carefully considered to meet the strict requirements of industrial piping systems. Below, we explore the structural features and significant advantages of three-way ball valves in detail.

Compact and Aesthetic Valve Body Design: The valve body of a three-way ball valve is manufactured through casting or forging processes. These processes not only ensure strength and durability but also result in a compact structure and appealing appearance. The compact design allows the valve to occupy minimal installation space, making it ideal for piping systems with limited room. The neat and aesthetic appearance enables it to integrate well into environments where equipment appearance matters.

Outstanding Sealing Performance and Automatic Functions: In O-type three-way ball valves, the valve core and stem rotate, keeping the valve core and seat in constant, tight contact during rotation. This design provides strong shearing capability, allowing the valve to effectively cut off fluid. In addition, by designing the valve seat with preload from a cylindrical spring or Belleville spring, the three-way ball valve also gains automatic compensation, self-sealing, and automatic cavity pressure relief. These functions are particularly crucial under harsh conditions such as high temperature and high pressure, ensuring sealing performance and improving system safety.

Smooth Operation and Low Operating Torque: The rotational design of the valve ball enables smooth operation and reduces operating torque. This means less force is required during operation, lowering difficulty, reducing the load on actuators, and cutting energy consumption.

Diverse Sealing Options: Three-way ball valves offer both soft and hard sealing options, and the sealing surfaces may also undergo hardening treatment. This range of options allows the valve to adapt to varied working conditions, whether corrosive media or high temperature and high pressure environments.

Automatic Pressure Relief Function: The automatic pressure relief design in the valve cavity is a major highlight. When residual medium in the cavity rises in temperature and causes abnormal pressure increase, the valve seat can automatically relieve pressure without needing a safety valve. This effectively prevents safety incidents caused by excessive internal pressure.

Anti-Static and Blow-Out-Proof Stem Structure: In flammable or explosive environments, static electricity may cause significant safety hazards. Three-way ball valves are equipped with anti-static structures that prevent static charge accumulation. Meanwhile, a blow-out-proof stem structure ensures the stem will not be ejected under high pressure, enhancing reliability.

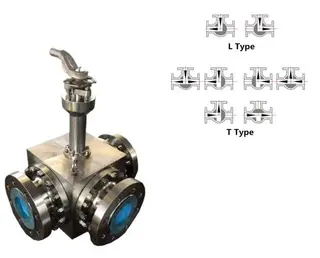

Flexible Flow Channel Design: Any port of a three-way ball valve can serve as an inlet without leakage, offering flexible installation. Depending on application needs, three-way ball valves can be manufactured in L-type or T-type configurations. L-type 3-way ball valve is used for flow direction switching, connecting two perpendicular channels. T-type 3-way ball valve is used for diversion, mixing, or direction switching, enabling interconnection among all three ports.

Convenient Maintenance and Inspection: After depressurizing the system, inspection and maintenance can be carried out without removing the entire valve body. This greatly simplifies maintenance, reduces time and cost, and improves equipment availability and reliability.

Types of Three-Way Ball Valves

Three-way ball valves come in various types based on structure, function, and application conditions. Each type has unique features and suitable applications. Understanding these types helps users select the right valve for efficient fluid control and system optimization.

1. L-Type Three-Way Ball Valves

L-type three-way ball valves connect two branch pipelines to a main pipeline. The ball's center is positioned at an angle to the main pipeline, and the ball has three channels: one main channel and two branch channels. As the ball rotates, it controls the on-off status and flow direction between the branches and the main line.

Advantages:

Flexible control of flow direction

Excellent sealing performance

Easy operation

Long service life

Commonly used in petroleum, chemical, pharmaceutical, and food industries.

2. T-Type Three-Way Ball Valves

A T-type three-way ball valve divides the main pipeline into two branches. The ball's center aligns with the axis of the main pipeline, and the three channels allow flow switching or on-off control between the main and branch pipelines.

Advantages:

Low flow resistance

High flow capacity

Simple structure

Easy installation

Excellent sealing

Widely used in petroleum, chemical, natural gas, and power industries.

3. Right-Angle and Y-Type Three-Way Ball Valves

Based on the angle between ports, three-way ball valves are divided into right-angle and Y-type.

Right-Angle Types: The adjacent flow port angle is 90°, and the ball passage can be L-type or T-type.

L-type: switches flow between perpendicular pipelines

T-type: supports mixing, diverting, and switching

Y-Type: Designed to solve flow turbulence and vortex issues near sharp turns in right-angle types. Two subtypes:

120° type: all three ports spaced evenly at 120°

135° type: port angles of 135°, 135°, and 45°

Y-type valves have lower flow resistance and improve transmission efficiency.

4. Hemispherical Three-Way Ball Valves

For media containing solid particles or powders prone to clogging, hemispherical three-way valves are ideal. Their semi-spherical core leaves no enclosed space between the valve seat and cavity, preventing material accumulation. This design enhances anti-clogging performance for special media.

Applications of Three-Way Ball Valves

Due to their unique structure and exceptional performance, three-way ball valves are widely applied across many industrial sectors.

Petroleum and Chemical Industry: Frequent diversion, mixing, and directional switching are required in pipeline systems. L-type and T-type three-way valves meet these needs, offering excellent sealing, easy operation, and long service life. Whether in crude oil transport, chemical blending, or product output, they ensure stable transmission and precise control.

Municipal Water Supply and Drainage: Three-way ball valves enable diversion and mixing to optimize water resource allocation. Their high flow capacity and low resistance help reduce energy consumption and improve system efficiency. Features like automatic pressure relief and anti-static design also improve safety and reliability.

Pharmaceutical and Food Industry: These industries require high sanitary standards. L-type valves provide flexible flow control and superior sealing performance. Long service life and easy operation reduce downtime and improve efficiency. Materials compliant with sanitation standards can be selected to ensure cleanliness and safety.

Natural Gas and Power Industry: Pipeline systems in these industries must withstand high pressure and temperature. Three-way ball valves offer automatic compensation, self-sealing, and cavity pressure relief to ensure stable performance in harsh environments. Their compact structure and excellent sealing also make them widely used in gas transport and cooling water circulation.

Conclusion

As a highly efficient control tool, the three-way ball valve plays an irreplaceable role in industrial piping systems. Its compact and aesthetic design, outstanding sealing performance, smooth operation, low operating torque, diverse sealing options, automatic pressure relief, anti-static and blow-out-proof structures, flexible flow channel design, and easy maintenance make it widely applicable across industries. By understanding its working principles, types, characteristics, applications, and maintenance essentials, users can better leverage its advantages to ensure stable operation of industrial pipeline systems.

Send your message to this supplier

Related Articles from the Supplier

What is a Duplex Spring Safety Valve?

- Sep 17, 2025

What is Explosion-Proof Electric Ball Valve

- Dec 22, 2025

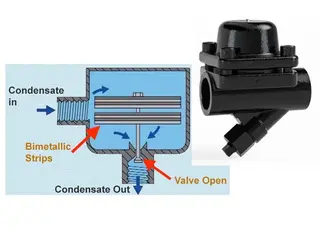

What is Bimetallic Steam Trap?

- Dec 26, 2025

What is Dual Plate Wafer Check Valve

- Jan 05, 2026

What is Double Eccentric Segmented Ball Valve

- Jan 13, 2026

What Is a Thermodynamic Steam Trap

- Jan 22, 2026

Related Articles from China Manufacturers

What is Three Way Ball Valve

- Jun 05, 2023

What Is a Three Way Ball Valve ?

- Nov 23, 2020

What is Handle Butterfly Valve

- Sep 08, 2015

What is EV Charging Load Management?

- Aug 09, 2024

What Is a Dynamic Load Balancing EV Charger?

- Sep 06, 2024

What is Butterfly Check Valve?

- May 07, 2020

What is a Pneumatic Actuator and how does it Work?

- Jun 17, 2020

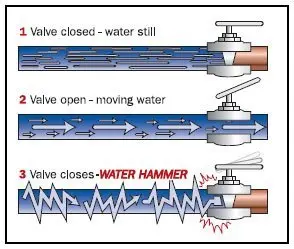

What is a Water Hammer

- Jul 13, 2020

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/what-is-three-way-ball-valve-structure-advantages-uses.html