What is Diaphragm Type Pneumatic Control Valve

In modern industrial production, precise control over fluid parameters such as flow, pressure, and temperature is critical for ensuring efficient, safe, and stable operation. Diaphragm type pneumatic control valves, as essential devices in industrial automation, play a vital role across numerous industries including chemical, petrochemical, power generation, and pharmaceuticals. These valves are widely recognized for their excellent performance, reliability, and adaptability to complex industrial processes. This article provides an in-depth discussion of the structure, selection, installation, maintenance, troubleshooting, and practical applications of diaphragm type pneumatic control valves, helping industrial engineers and operators better understand and utilize these highly effective tools.

Structure & Principle of Diaphragm Type Pneumatic Control Valve

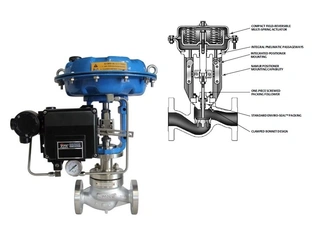

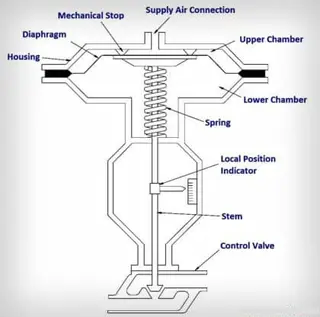

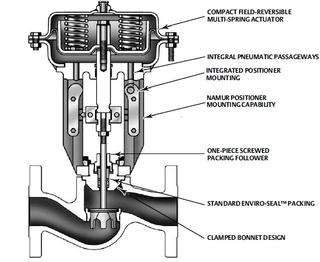

Diaphragm type pneumatic control valves primarily consist of a diaphragm actuator, valve body, and valve plug. The working principle relies on compressed air to drive the diaphragm, converting the diaphragm's elastic deformation into linear movement of the valve stem. This movement then drives the valve plug to adjust the opening degree of the valve, thereby controlling the flow, pressure, and temperature of the fluid within the pipeline accurately.

To achieve higher precision, diaphragm type pneumatic control valves are often used in conjunction with a valve positioner. The valve positioner receives input signals from the controller and converts them into corresponding output signals to adjust the valve opening precisely. This closed-loop control system effectively overcomes friction between the valve packing and the valve stem, accelerates valve response, allows segmented control, and modifies the flow characteristics of the valve, resulting in more accurate and stable regulation.

How to Select Diaphragm Type Pneumatic Control Valves?

Proper selection of diaphragm type pneumatic control valves is crucial to ensure optimal performance in practical applications. The selection process must consider multiple factors, including valve structure, operating mode, flow characteristics, and the flow coefficient (CV value).

1. Valve Structure

Diaphragm type pneumatic control valves are commonly available in three structural types: single-seated straight-through valves, double-seated straight-through valves, and high-pressure angle-type valves. Each structure has unique characteristics and is suitable for different process conditions:

- Single-Seated Straight-Through Valve: This valve type is characterized by minimal leakage; however, the fluid acting on the single plug generates significant unbalanced forces. Therefore, it is most suitable for applications requiring low leakage, small pipe diameters, and low differential pressures. For example, in fine chemical production, where precise flow control is essential while maintaining strict system sealing, single-seated straight-through valves are an ideal choice.

- Double-Seated Straight-Through Valve: Equipped with two plugs acting in opposite directions within the valve body, the forces largely cancel each other out, allowing the valve to handle larger differential pressures. However, the complex internal flow path increases the risk of erosion under high-pressure conditions, and it is less suitable for high-viscosity media or media containing suspended particles or fibers. Additionally, due to manufacturing limitations, simultaneous tight closure of both plugs is difficult. Leakage may increase during closing, especially under high- or low-temperature conditions, where different thermal expansion coefficients of the materials can cause significant leakage.

- High-Pressure Angle-Type Valve: The valve body is configured in a right-angle design, providing a simple flow path with low resistance and minimal erosion from high-speed fluids. This type is particularly suitable for high-pressure, high-viscosity, or particulate-laden fluids. It is also ideal for handling vapor-liquid mixtures or fluids prone to flashing or cavitation. High-pressure angle-type valves can prevent coking, sticking, or clogging issues effectively. For instance, in petroleum refining, when processing crude oil with high impurity content, these valves ensure stable system operation and reliable control.

2. Operating Mode

Diaphragm type pneumatic control valves can be configured as air-to-open (fail-closed) or air-to-close (fail-open) valves. The selection of the operating mode primarily depends on process safety requirements and operational considerations—specifically, the default valve position in the event of signal loss and the potential hazard it may cause.

- Air-to-Open (Fail-Closed) Valves: These valves close when signal pressure is interrupted and are selected when leaving the valve closed poses minimal hazard.

- Air-to-Close (Fail-Open) Valves: These valves open when signal pressure is lost, and are preferable in cases where stopping fluid flow during a signal loss is critical, such as pipelines carrying hazardous chemicals.

3. Flow Characteristics

Flow characteristic is one of the most important performance indicators of control valves. Common ideal flow characteristics include linear, equal percentage (logarithmic), quick-opening, and parabolic types.

- Linear Flow Characteristic: Flow changes proportionally with valve opening. At low flow, small changes in opening result in large relative changes in flow, whereas at high flow, the relative change is smaller. Linear valves perform poorly at small openings and can cause oscillations, making them unsuitable for systems with large load variations but ideal for steady load systems.

- Equal Percentage Flow Characteristic: Flow changes gradually at low loads and more significantly at higher loads, providing smooth regulation across variable operating conditions. Equal percentage valves maintain stable operation near fully closed or fully open positions, ensuring effective control for processes with fluctuating loads.

4. Flow Coefficient (CV Value)

The flow coefficient, CV (or KV in China), is a critical parameter representing the valve's maximum flow capacity under specified conditions. Correct CV calculation and selection are essential to ensure reliable flow control. The CV value differs for liquids, gases, steam, and other media. Once the required CV is calculated based on fluid properties and operating conditions, the appropriate valve size can be chosen according to technical specifications.

How to Install Diaphragm Type Pneumatic Control Valves?

Proper installation is essential to ensure the safety, reliability, and accuracy of diaphragm type pneumatic control valves. Key installation considerations include:

1. Valve Positioning

Whenever possible, install the valve horizontally, aligned with the process pipeline, and maintain a vertical actuator orientation. If vertical or horizontal cylinders are required due to space constraints, ensure the actuator can move freely without obstruction.

Maintain straight pipe sections before and after the valve, ideally at least ten times the pipe diameter, to minimize turbulence and improve control precision.

Avoid installing valves in high-vibration areas. Extend the pump outlet or use vibration dampening measures if necessary. Provide at least 50 cm of maintenance space to facilitate inspection and repair.

2. Pipeline Connection

Clean the pipeline thoroughly to remove debris, welding slag, or foreign objects before installation, as these can interfere with valve operation. Use double-ended bolts and metal spiral gaskets for reliable sealing.

For diameter mismatches between the valve and pipeline, use reducing connectors. Threaded connections are suitable for small valves, provided they ensure secure and leak-free joints. Ensure the flow direction arrow on the valve body matches the actual fluid flow.

3. Auxiliary Device Installation

For valves with handwheel mechanisms, disengage the actuator from the valve plug by loosening the cross-connection with a hex wrench, allowing manual control independent of air pressure.

When installing positioners or handwheel mechanisms, ensure ease of observation, adjustment, and operation. Positioners must be matched to the valve for accurate and responsive control.

How to Maintain Diaphragm Type Pneumatic Control Valves?

Regular maintenance is essential for ensuring long-term stable operation:

1. Routine Inspection

Follow scheduled maintenance plans or inspect the valve during downtime. Examine the valve plug, seat, stem, and packing for wear, damage, or aging.

Polish scratched valve plugs, straighten slightly bent stems, or replace severely damaged components. Replace aging or dry packing to reduce stem friction, prevent wobbling, and maintain smooth valve operation.

2. Troubleshooting

If the valve fails to respond, check for diaphragm damage, air leaks, or insufficient signal pressure. Repair or replace the diaphragm as necessary.

If the valve operates but fails to regulate flow, inspect for plug detachment or pipeline blockages, clear the obstructions, and repair the valve as needed.

Slow response or stem wobble may result from worn packing, foreign particles, scratches, or sticky media. Minor scratches can be smoothed; severe damage requires stem replacement. Clean blocked valve bodies using appropriate methods, such as steam or water flushing, depending on the blockage.

Industrial Application Case Studies

- Chemical Industry: In chemical production, precise control of reactant flow and temperature is often critical. For example, in esterification reactions, alcohol and acid must be mixed in specific ratios and reacted at controlled temperatures. Diaphragm type pneumatic control valves precisely regulate the flow of both reactants and automatically adjust cooling water based on temperature variations, ensuring optimal reaction conditions. This precise control improves product quality and yield while minimizing energy waste and by-product formation.

- Petrochemical Industry: In petroleum refining, crude oil contains impurities and components with varying boiling points that must be separated and distilled. Diaphragm type pneumatic control valves regulate reflux flow and temperature in distillation towers, as well as steam flow to reboilers, ensuring product quality and process stability. Accurate valve control is essential for the reliable operation of the entire refining process.

- Power Industry: In thermal power plants, boiler combustion requires precise control of fuel supply and air flow. Diaphragm type pneumatic control valves are extensively used in fuel oil and air pipelines. Adjusting fuel flow ensures complete and stable combustion, while air flow regulation optimizes combustion efficiency and reduces emissions. Accurate control contributes to safe and efficient power generation, supporting both operational stability and environmental compliance.

Conclusion

Diaphragm type pneumatic control valves are efficient, reliable, and essential tools in industrial automation, offering precise control of flow, pressure, and temperature. Proper selection, correct installation, and regular maintenance ensure that these valves perform optimally in practical applications. As industrial automation technology continues to advance, diaphragm type pneumatic control valves will see broader applications and improved performance, providing a reliable foundation for safe, efficient, and stable production.

In practice, users should select valves based on specific process requirements, follow operational protocols strictly, and train personnel to understand valve performance and operation. This approach maximizes the advantages of diaphragm type pneumatic control valves, enhancing both economic and operational benefits for industrial enterprises.

Send your message to this supplier

Related Articles from the Supplier

What is Diaphragm Type Pneumatic Control Valve

- Jan 24, 2026

What is a Duplex Spring Safety Valve?

- Sep 17, 2025

What is Explosion-Proof Electric Ball Valve

- Dec 22, 2025

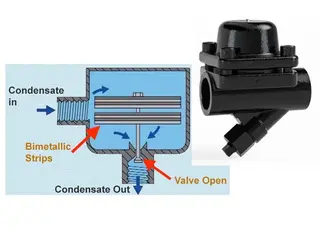

What is Bimetallic Steam Trap?

- Dec 26, 2025

What is Dual Plate Wafer Check Valve

- Jan 05, 2026

What is Double Eccentric Segmented Ball Valve

- Jan 13, 2026

Related Articles from China Manufacturers

What is JONLOO Diaphragm Valve

- Sep 30, 2019

What Is PPH Diaphragm Valve

- Jan 11, 2024

What is a diaphragm valve?

- Apr 04, 2019

EXACTLY WHAT IS ACTUALLY A DIAPHRAGM PUMP?

- Mar 10, 2018

What Is Special about Sous Vide Cooking Method?

- Jul 12, 2017

What Is the Seamless Steel Pipe for

- Sep 16, 2013

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/what-is-diaphragm-type-pneumatic-control-valve.html