Wafer Check Valves: Functions, Features and Selection

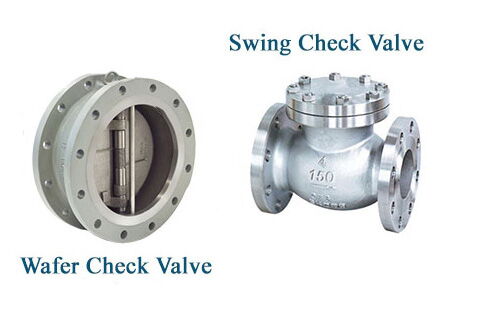

In industrial piping systems, there is a type of valve that may not appear remarkable at first glance but plays a crucial role: the wafer check valve. Do not underestimate this small valve; it is a key component that ensures the normal operation of piping systems and prevents backflow. Today, let us take an in-depth look at the wafer check valve and its two common forms: the double-disc wafer check valve and the single-disc wafer check valve.

What is a Wafer Check Valve?

A wafer check valve is a universal one-way fluid valve. Its name may sound somewhat complex, but its function is actually very straightforward. This valve is connected to the pipeline using a wafer-style connection, like clamping two slices of bread together, making installation very convenient. It is lightweight and compact, making it ideal for installation between flanges without taking up much space.

The internal structure of the wafer check valve is also ingenious. It consists of two semicircular springs and valve plates fixed to the valve body with pins. When fluid flows normally, the pressure of the fluid overcomes the spring resistance, opening the valve and allowing smooth flow. When the fluid stops or flows in reverse, the deformation of the spring quickly closes the valve, like an automatic door, promptly preventing backflow. This process is extremely fast, instantly protecting the pipeline from water hammer damage.

Water hammer refers to the huge impact force generated when fluid in a pipeline suddenly stops or changes direction. If not controlled in time, this impact can cause severe damage to the piping system, and even lead to safety accidents. The fast-closing characteristic of the wafer check valve acts like a timely "brake," effectively preventing water hammer.

Classification of Wafer Check Valves: Double-Disc vs. Single-Disc

Wafer check valves are mainly divided into double-disc wafer check valves and single-disc wafer check valves. Although both belong to the wafer check valve category, they have distinct structural and performance characteristics, suitable for different application scenarios.

1. Double-Disc Wafer Check Valve

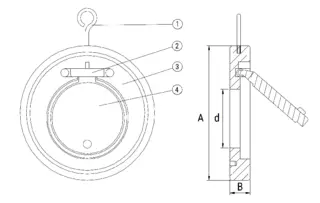

The double-disc wafer check valve is a type of wafer check valve, named for its unique dual-disc structure. This valve consists of two discs fixed to the valve body, which rotate to open and close the valve. When fluid flows forward, the discs rotate upward, opening the valve and allowing fluid to pass freely. When fluid flows backward, the discs rotate downward under the reverse force, closing the valve to prevent backflow.

The advantage of the double-disc wafer check valve lies in its highly efficient closure performance. With two discs working simultaneously, it can close more completely, effectively preventing leakage. In high-flow and high-pressure pipeline systems, the double-disc wafer check valve can close faster without affecting system efficiency. Its design allows it to withstand larger pressures and flow rates, making it suitable for use in complex industrial environments.

Another feature of the double-disc wafer check valve is its compact structure, occupying minimal space. It adopts a short-face design, and its rational structure allows installation even in spaces with limited room. In addition, O-ring seals on the valve discs provide excellent sealing performance, effectively preventing medium leakage. Due to the short closing travel of the discs and spring loading, the discs can open and close rapidly under very small differential pressure, ensuring sensitive operation.

However, the double-disc wafer check valve also has drawbacks. Its structure is relatively complex and the cost is higher. Additionally, during reverse flow, it may produce some noise and vibration. Nevertheless, these shortcomings do not affect its widespread application in industrial fields.

2. Single-Disc Wafer Check Valve

In contrast, the single-disc wafer check valve generally consists of a single disc fixed to the valve cover, which rotates to open and close the valve. When fluid flows forward, the disc rotates upward, opening the valve and allowing fluid to pass freely. When fluid flows backward, the disc rotates downward under the reverse force, closing the valve to prevent backflow.

The advantage of the single-disc wafer check valve lies in its simple structure and ease of maintenance. Its design is relatively straightforward, without complex components, making maintenance and repair more convenient. This valve is suitable for low-flow and high-pressure pipeline systems and can meet general industrial requirements. The single-disc wafer check valve is relatively low-cost, making it an economical choice.

However, the single-disc wafer check valve also has limitations. Its closure is not as thorough, and leakage may occur. Under high-speed or large-flow conditions, it closes less quickly, which may affect the efficiency of the pipeline system. Therefore, when selecting a single-disc wafer check valve, it is necessary to evaluate the specific usage scenario and requirements.

How to Choose the Appropriate Wafer Check Valve?

When selecting a wafer check valve, multiple factors must be considered to ensure the chosen valve meets actual usage needs.

1. Fluid Characteristics

The characteristics of the fluid are an important basis for selecting a wafer check valve. Different fluids may have different temperatures, pressures, and corrosiveness. For example, if the fluid is highly corrosive, a valve made of materials with good corrosion resistance should be chosen. Fluid viscosity also affects valve performance. High-viscosity fluids may require higher pressure to open the valve, so viscosity must be considered during selection.

2. Flow Rate and Pressure

Flow rate and pressure are key factors affecting the performance of wafer check valves. In high-flow and high-pressure pipelines, a double-disc wafer check valve is usually a better choice. It can close quickly to prevent backflow without significantly affecting system efficiency. In low-flow and low-pressure pipelines, a single-disc wafer check valve is sufficient. Its simple structure and low cost can effectively prevent backflow.

3. Installation Space

Installation space is also a factor to consider. Although the double-disc wafer check valve is compact, it still requires some space for installation. In limited spaces, a smaller single-disc wafer check valve may be preferable. The installation direction of the valve is also important. Double-disc wafer check valves can be installed horizontally or vertically, but for DN sizes above 400, horizontal installation is generally recommended. Before installation, pipelines should be cleaned, and valves fully inspected to ensure no damage. The installation direction must align the arrow on the valve with the fluid flow direction.

4. Maintenance and Cost

Maintenance and cost are also considerations when choosing a valve. Double-disc wafer check valves, although superior in performance, have a more complex structure and higher maintenance cost. Single-disc wafer check valves are simple, easy to maintain, and low-cost. Selection should consider actual maintenance capabilities and budget.

Applications of Wafer Check Valves

Wafer check valves are widely used in industries such as petroleum, chemical, power, and water treatment, where they play important roles.

Petroleum Industry: During oil extraction and transportation, wafer check valves prevent backflow and protect pipelines from water hammer. Double-disc wafer check valves, with their high-efficiency closure and ability to withstand high pressure and flow, are widely used in oil pipelines.

Chemical Industry: During chemical production, the transportation of various chemical media requires strict control. Wafer check valves prevent backflow, avoiding mixing of different media and ensuring smooth chemical processes. Single-disc wafer check valves, with simple structure and low cost, are suitable for low-flow, low-pressure chemical pipeline systems.

Power Industry: In power systems, wafer check valves prevent backflow of cooling water and other media, protecting equipment. The rapid closure of double-disc wafer check valves effectively reduces water hammer, protecting pipelines, making them widely used in power plant cooling systems.

Water Treatment: In water treatment, wafer check valves prevent backflow of wastewater, protecting water sources. Single-disc wafer check valves, with simple structure and ease of maintenance, are suitable for small water treatment systems. Double-disc wafer check valves are suitable for large wastewater plants, effectively preventing backflow and protecting the environment.

Conclusion

Although small in appearance, wafer check valves play an important role in industrial piping systems. Both double-disc and single-disc types provide unique advantages that ensure smooth pipeline operation. Selecting a wafer check valve requires comprehensive evaluation of the specific usage scenario and requirements to ensure the chosen valve meets actual needs. Proper maintenance and care can extend the service life of wafer check valves and improve their performance.

Send your message to this supplier

Related Articles from the Supplier

What is Dual Plate Wafer Check Valve

- Jan 05, 2026

Wafer Butterfly Valves vs. Flanged Butterfly Valves

- Dec 29, 2025

Related Articles from China Manufacturers

Working Principles of Wafer Check Valves

- May 25, 2017

Precautions for Installation of Wafer Check Valves

- Sep 29, 2022

The Installation Notes of Wafer Check Valve

- Feb 25, 2017

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/wafer-check-valves-functions-features-and-selection.html