Wafer Butterfly Valves vs. Flanged Butterfly Valves

In industrial and construction applications, valves are indispensable components of piping systems. They are responsible for controlling fluid flow, ensuring the safety and efficient operation of the system. As a widely used type of valve, butterfly valves offer reliable solutions across various applications due to their unique design and functionality. Among the many butterfly valve products, wafer butterfly valves and flanged butterfly valves are the most common types. Each has its own distinct features and advantages, suitable for different working conditions and requirements. This article provides a detailed introduction to the functions, characteristics, applications, and selection of these two types of butterfly valves.

Basic Functions and Importance of Butterfly Valves

A butterfly valve is a type of valve that controls fluid flow by rotating a disc. Its primary function is to maintain a seal, preventing backflow under bidirectional pressure, ensuring that the fluid flows in only one direction. This design is critical in many systems, especially in scenarios where backflow must be prevented to avoid contamination or equipment damage. The sealing performance of butterfly valves mainly relies on precisely machined sealing components such as O-rings and gaskets, as well as the flat valve faces on the upstream and downstream sides. These sealing components fit tightly to ensure good sealing performance under various working conditions.

Features and Advantages of Wafer Butterfly Valves

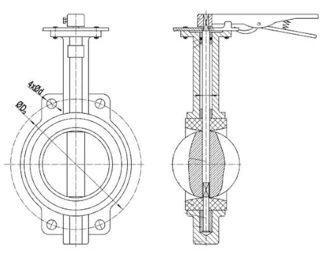

- Structure and Design: Wafer butterfly valves have no flanges at both ends of the valve body. Instead, they are connected to pipe flanges through a set of guide bolt holes. This design makes installation and removal relatively simple and quick. Without flanges, wafer butterfly valves are lighter, compact, and occupy less space, making them especially suitable for areas with limited space.

- Cost-Effectiveness: The price of wafer butterfly valves is relatively lower, approximately two-thirds that of flanged butterfly valves. This price advantage makes them an ideal choice for many budget-sensitive projects. Additionally, due to their simple structure, manufacturing costs are also relatively low, further reducing the overall cost.

- Installation and Maintenance: The installation of wafer butterfly valves is relatively simple. The valve is placed between two pipe flanges, and the flanges are fixed with bolts. This installation method not only saves time but also reduces potential errors during installation. In terms of maintenance, wafer butterfly valves also have advantages. Their compact structure allows for easier and faster operations such as disassembly and replacement of sealing components.

- Applications: Wafer butterfly valves are widely used in ventilation systems, water treatment facilities, and light industrial production. These scenarios typically have relatively low pressure and temperature requirements, and the medium-to-low pressure (e.g., PN10) and medium-to-small diameter designs of wafer butterfly valves meet these needs. Additionally, their compact structure and lightweight design make them perform well in space-limited environments.

Features and Advantages of Flanged Butterfly Valves

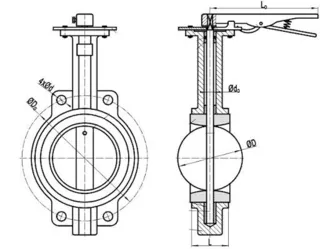

- Structure and Design: Flanged butterfly valves have flanges at both ends of the valve body, connected to pipe flanges with bolts. This design enhances the stability and reliability of the connection, making it more suitable for high-pressure and large-diameter conditions. Flanged butterfly valves have longer, heavier valve bodies with more complex structures but provide higher pressure resistance and vibration resistance.

- Sealing Performance: The sealing performance of flanged butterfly valves is relatively superior, especially in high-pressure environments. Their tighter and more secure connections effectively prevent fluid leakage. This makes flanged butterfly valves widely used in industries such as petrochemical, power, and utilities, particularly in systems with higher operational pressure requirements.

- Cost and Durability: Although flanged butterfly valves are more expensive, their durability and long-term reliability make them an economically efficient choice. Additional materials and processing are required for the flanges, so the cost of flanged butterfly valves is relatively high. However, in the long run, their robust design ensures stability during extended operation and reduces the frequency of maintenance and replacement.

- Applications: Flanged butterfly valves are suitable for medium-to-high pressure (e.g., PN16 and above), large-diameter, and high-vibration conditions. For example, in main water supply pipelines and chemical process lines, flanged butterfly valves provide stable performance and reliable sealing. Their higher pressure resistance and vibration resistance make them ideal for these demanding applications.

Comparison Between Wafer and Flanged Butterfly Valves

After understanding the characteristics and advantages of wafer and flanged butterfly valves, we can compare the two types in detail to clearly show their differences and help you make an informed choice according to your needs.

1. Installation and Removal

The installation of wafer butterfly valves is relatively simple and fast. The valve is placed between two pipe flanges and secured with bolts. This method saves time and labor costs. However, disassembly may require loosening all bolts on both sides of the flanges. In contrast, the installation of flanged butterfly valves is relatively more complex, but their solid design ensures reliability during long-term operation. Flanged valves do not require loosening all bolts on both sides of the flanges during disassembly, which reduces complexity.

2. Sealing Performance

Flanged butterfly valves generally have better sealing performance than wafer valves, especially in high-pressure environments. Their connections are tighter and more secure, effectively preventing fluid leakage. Although wafer valves also provide good sealing, their stability under extreme high-pressure conditions may be slightly lower.

3. Cost and Price

Wafer butterfly valves are relatively cheaper, about two-thirds the cost of flanged valves. This price advantage makes them ideal for budget-sensitive projects. Additionally, their simple structure reduces manufacturing costs, further lowering overall costs. Flanged butterfly valves, due to their complex structure, require additional materials and processing, making them more expensive. However, their durability and reliability make them an economically efficient choice in the long term.

4. Applications

Wafer butterfly valves are widely used in ventilation systems, water treatment facilities, and light industrial production. These scenarios usually have lower pressure and temperature requirements, and the medium-to-low pressure (e.g., PN10) and medium-to-small diameter designs of wafer valves meet these needs. Their compact structure and lightweight design perform well in space-limited environments. Flanged butterfly valves are suitable for industries such as petrochemical, power, and utilities, particularly in systems with higher operational pressure requirements. Their high pressure resistance and vibration resistance make them ideal for medium-to-high pressure (PN16 and above), large-diameter, and high-vibration applications.

How to Choose the Right Butterfly Valve?

Choosing the right butterfly valve requires considering multiple factors, including pressure, temperature, space, cost, and application. The following are key considerations when selecting a butterfly valve:

1. Pressure and Temperature

If your application requires high pressure (PN16 and above) or high-temperature conditions, it is recommended to choose flanged butterfly valves. Their structural design allows them to withstand higher pressure and temperature, providing more reliable performance. Wafer butterfly valves are more suitable for medium-to-low pressure (PN10 and below) and lower-temperature conditions.

2. Space Constraints

If installation space is limited, wafer butterfly valves may be the better choice. Their compact structure and lightweight design occupy less space, making them ideal for space-constrained environments. Flanged valves, with longer and heavier bodies, require more space for installation and maintenance.

3. Cost Considerations

If your project budget is limited, the price advantage of wafer butterfly valves makes them an economical choice. Their manufacturing cost is lower, and installation is relatively simple, saving time and expenses. Flanged valves, although more expensive, offer durability and reliability, providing long-term advantages.

4. Application Scenarios

Choose the valve type based on your specific application. Wafer butterfly valves are widely used in ventilation systems, water treatment facilities, and light industrial production, where pressure and temperature requirements are relatively low. Flanged butterfly valves are better suited for petrochemical, power, and utility industries, particularly in systems requiring higher operational pressures.

Conclusion

Wafer and flanged butterfly valves each have unique characteristics and advantages, suitable for different applications. Wafer valves, with their compact structure, low cost, and ease of installation, are widely used in medium-to-low pressure and medium-to-small diameter systems. Flanged valves, with superior sealing performance, high pressure resistance, and vibration resistance, are ideal for demanding industries such as petrochemical and power. When selecting a butterfly valve, factors including pressure, temperature, space, cost, and application must be considered to ensure the most suitable valve type is chosen. Proper installation and maintenance are also key to ensuring long-term stable operation. By understanding the core differences between wafer and flanged butterfly valves and combining this knowledge with your specific needs, you can select the most suitable butterfly valve for your piping system, ensuring safe and efficient operation.

Send your message to this supplier

Related Articles from the Supplier

Wafer Butterfly Valves vs. Flanged Butterfly Valves

- Dec 29, 2025

What is Dual Plate Wafer Check Valve

- Jan 05, 2026

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/wafer-butterfly-valves-vs-flanged-butterfly-valves.html