High-Temperature Ball Valves Material Selection

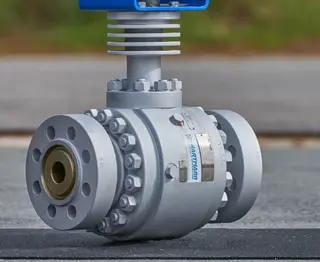

In numerous industrial fields, high-temperature control has always been a core concern for manufacturers and design institutions. Especially in the field of automation control and in conditions involving high-temperature ball valves, regulating and controlling temperature in high-temperature environments is complex and challenging. This challenge is mainly reflected in the extreme difficulty of achieving reliable fluid shutoff under high-temperature conditions, primarily due to jamming and difficulty in fluid cut-off caused by thermal expansion.

Material Selection Challenges for High-Temp Ball Valves

In high-temperature environments, the performance and stability of high-temperature ball valve materials are severely tested. Material selection not only concerns whether the valve can operate normally but also directly affects the safety and reliability of the entire system. So, what complexities does material selection for high-temperature ball valves face? Let us explore this issue in depth.

1. Test of High Temperature on Material Performance

In high-temperature environments, the performance and stability of high-temperature ball valve materials are severely challenged. Material selection not only determines whether the valve can function properly but also directly impacts the safety and reliability of the entire system. When the temperature exceeds 450°C, changes in material properties become particularly significant. Among currently available conventional materials, the maximum withstand temperature is roughly around 500°C. However, many industrial scenarios require coping with even higher temperatures.

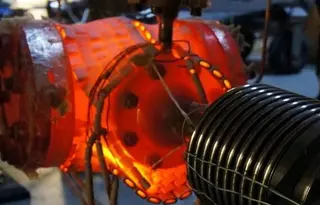

2. Material Selection for Different Temperature Ranges

When the temperature exceeds 538°C, chromium-molybdenum steel becomes a common choice, offering good high-temperature strength and oxidation resistance, meeting the needs of most high-temperature conditions. For extreme high-temperature environments of around 1035°C, SUS310S stainless steel is a relatively ideal choice. It should be noted that the carbon content of this stainless steel must be strictly controlled between 0.04% and 0.08% to ensure stability and mechanical properties at high temperatures. For even higher temperature conditions, such as above 1035°C, non-metallic heat-resistant linings or special high-temperature, high-strength alloys are required. These materials can withstand extreme high temperatures up to 1200°C, providing excellent high-temperature stability and strength, enabling high-temperature ball valves to be applied in special high-temperature scenarios.

3. Consideration of Multiple Factors in Material Selection

When selecting materials for the valve body and internal components of high-temperature ball valves, multiple factors must be comprehensively considered, including heat resistance, mechanical properties, corrosion resistance, and cost. Heat resistance is the primary consideration, ensuring that materials maintain performance stability under high-temperature conditions; mechanical properties determine the strength and reliability of the valve under high-temperature and high-pressure conditions; corrosion resistance ensures the service life of the valve when facing various complex fluid media; and cost must be minimized while meeting performance requirements to enhance market competitiveness. These factors interact with each other, requiring continuous material research and engineering innovation to find the optimal balance and meet the ever-evolving demands of high-temperature control.

Sealing Challenges & Solutions for High-Temp Ball Valves

After addressing the complexity of material selection for high-temperature ball valves, we must also confront another key challenge, sealing technology. Sealing performance is one of the core factors for the reliable operation of high-temperature ball valves. In high-temperature environments, traditional sealing methods often fail, necessitating in-depth study of sealing technology challenges and effective solutions for high-temperature ball valves.

1. Limitations of Traditional Sealing Materials

In high-temperature environments, traditional sealing materials such as PTFE packing are generally suitable only for temperatures below 150°C. When temperatures rise, these materials easily experience thermal expansion, aging, and failure, resulting in decreased sealing performance. For example, O-rings, PTFE materials, and elastic metal materials struggle to maintain reliable sealing in high-temperature environments and cannot meet the sealing requirements of high-temperature ball valves.

2. High-Temp Sealing Materials and Structural Innovations

To overcome these challenges, engineers continuously explore new sealing materials and structures. Flexible graphite packing has become an important solution, with a heat resistance of up to 600°C, far exceeding the limits of traditional packing. Using flexible graphite packing not only reduces problems caused by high-temperature effects on the packing but also lowers the height of extended valve covers, making the valve more compact and adaptable to high-temperature environments. In addition, by introducing a “rotary-type coarse valve stem” design, the overall strength and stability of the ball valve can be improved. This design strengthens the stem, helping to cope with mechanical stress and vibration under high-temperature conditions, thereby solving sealing and operational problems in high-temperature environments.

3. Seal Structures for Different Temperature Conditions

Under temperatures below 500°C, special composite graphite soft-seal valve seat technology is a feasible sealing solution. This technology combines the high-temperature stability of composite graphite with the advantages of soft sealing, resisting extrusion and expansion at high temperatures and maintaining good sealing performance. However, under high-temperature conditions above 500°C, metal-to-metal hard sealing becomes a primary choice. While hard-to-hard high-temperature ball valves cannot achieve zero leakage, they can withstand higher pressures and temperatures while maintaining good shut-off performance. The sealing characteristic of high-temperature regulating ball valves mainly involves metal sealing pairs, whose advantages include a wide applicable temperature range and similar thermal expansion coefficients among metals. Proper selection ensures basic consistency, facilitating coordinated thermal deformation. The disadvantage is that the materials are hard, requiring high contact pressure to achieve sealing, resulting in significant wear between the seat and ball and a large operating torque. Therefore, most high-temperature ball valves adopt elastic sealing pairs, which are reliable, provide strong elastic compensation, have a wide temperature range, and are suitable for both floating and trunnion-mounted ball valves.

Performance Optimization of High-Temp Ball Valves

After overcoming the complexity of material selection and sealing technology challenges, the next critical step is structural design and performance optimization. A reasonable and optimized structure not only fully utilizes the advantages of selected materials but also effectively enhances the overall performance of high-temperature ball valves, ensuring more stable and reliable operation in high-temperature environments.

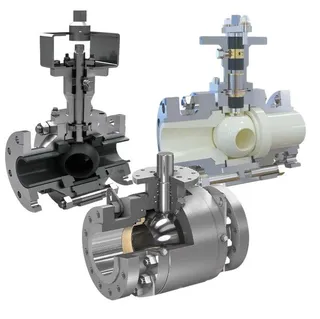

1. Hard-Seal High-Temperature Ball Valve Structure

A hard-seal high-temperature ball valve consists of the valve body, ball, stem, metal seat, and flexible graphite sealing ring between the seat and valve body. Two valve seats are symmetrically embedded in the valve body around the stem axis. The seats slide within grooves in the body, and the sealing between the seat and body is achieved by flexible graphite sealing rings. Due to the compressibility of the flexible graphite rings, this ball valve structure can operate within a certain temperature range without jamming caused by thermal expansion of the ball, suitable for conditions not exceeding 343°C.

2. Metal Elastic Ring Sealing Structure

High-temperature ball valves use metal elastic rings as valve seat seals to compensate for variations in temperature, pressure, and wear affecting sealing performance. The valve consists of the body, ball, stem, metal seat, flexible graphite sealing ring between seat and body, metal elastic ring, elastic ring compression ring, and gasket. One of the two valve seats is a metal seat that slides within the valve body groove, while the other is a deformable metal elastic ring seat. When the ball expands due to heat, the elastic seat deforms to prevent jamming, ensuring smooth operation.

3. Disc Spring-Loaded Seal Structure

High-temperature regulating ball valves use disc spring-loaded seal structures. The valve consists of the body, ball, stem, rear seat, rear seat sealing ring, front seat, front seat sealing ring, compression ring, and disc spring. The front seat, front seat sealing ring, and compression ring form a unit pressed by the disc spring. After assembly, the disc spring provides initial sealing force while compressing the sealing ring between seat and body, achieving sealing. Two valve seats are symmetrically embedded in the body around the stem axis. The seats slide in grooves, and when the ball expands due to heat, the seat assembly slides while the disc spring deforms, preventing the ball from jamming.

Conclusion

High-temperature ball valves play a key role in industrial automation and high-temperature conditions, with their performance directly related to system safety and reliability. This article comprehensively analyzes the technical challenges and solutions of high-temperature ball valves from material selection, sealing technology, to structural design. In high-temperature environments, valve materials must balance heat resistance, mechanical performance, and corrosion resistance. Proper selection of chromium-molybdenum steel, stainless steel, or high-temperature alloys ensures stable operation across different temperature ranges. Sealing technology must overcome the limitations of traditional materials, achieving reliable sealing at high temperatures using flexible graphite, metal elastic rings, or disc spring-loaded seal structures. Structural optimization solves thermal expansion-induced jamming through sliding seats, elastic compensation, and disc spring-loaded mechanisms. Overall, the synergistic effect of materials science, sealing innovation, and structural optimization forms the core guarantee for efficient and stable operation of high-temperature ball valves, providing reliable technological support for fluid control under high-temperature conditions.

Send your message to this supplier

Related Articles from the Supplier

High-Temperature Ball Valves Material Selection

- Dec 17, 2025

How Does a High Performance Butterfly Valve Work

- Dec 14, 2024

Related Articles from China Manufacturers

High-Temperature Ball Valve Material Selection

- Aug 21, 2025

Sealing Solutions for High-Temperature Ball Valves

- Feb 07, 2025

The Structure of Ultra-high Temperature Ball Valves

- Jul 14, 2022

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/high-temperature-ball-valves-material-selection.html