High-Temperature Valve Sealing: Technology and Challenges

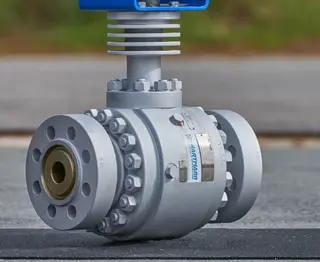

In industrial production, valve sealing technology is one of the key links to ensure the safe operation of equipment. From petroleum refining to chemical production, from pharmaceutical processes to energy generation, every stage relies on the precise control and reliable sealing of valves. Especially in high-temperature environments, valve sealing faces many challenges. High temperature not only tests the tolerance of sealing materials but also puts higher requirements on the stability of the sealing structure. Once sealing fails, it may lead to leakage of hazardous chemicals, fire, or even explosion, resulting in serious casualties and environmental pollution. Therefore, the research and application of high-temperature valve sealing technology have always been an important topic in the industrial field.

This article will deeply explore the common problems, solutions, and material selection of high-temperature valve sealing, helping readers better understand and deal with this complex technical challenge. We will start with common valve packing sealing structures, analyze the performance characteristics of different materials in high-temperature environments, discuss the challenges faced by high-temperature sealing rings, and propose corresponding solutions. Through comprehensive introduction and analysis, readers will be able to better grasp the key technologies of high-temperature valve sealing, providing strong guarantees for the safe operation of industrial production.

The Importance of High-Temperature Valve Sealing

In industries such as petroleum, chemical, and pharmaceutical, the sealing performance of high-temperature valves is directly related to the safety and efficiency of production. Once sealing fails, it may cause hazardous chemical leakage, fire, or even explosion, leading to serious casualties and environmental pollution. Therefore, selecting suitable sealing materials and structures to ensure reliable sealing of high-temperature valves is an important link in industrial production that cannot be ignored.

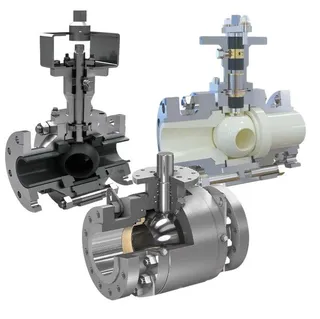

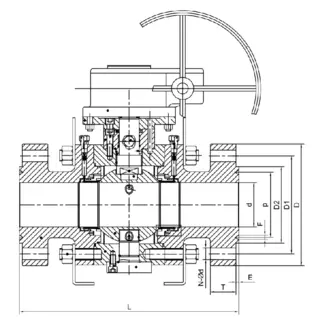

Common Valve Packing Sealing Structures

Valve packing sealing is one of the most common forms of high-temperature valve sealing. Its main structure includes gland, packing gland, bushing, and packing. Packing is the key material of sealing, and its performance directly affects the sealing effect. To achieve a good sealing effect, packing usually needs to have the following characteristics: dense structure, good chemical stability, and low friction coefficient.

1. PTFE Packing

Polytetrafluoroethylene (PTFE) packing is a commonly used packing material. It is made of pure PTFE dispersion resin as raw material and processed through special techniques. This material has high lubricity, non-stick properties, electrical insulation, and good anti-aging performance, and is therefore widely used in petroleum, chemical, pharmaceutical, and other fields. Its application range is relatively wide, with a maximum service temperature of 260℃, a maximum service pressure of 2.0MPa, and a pH value range of 0–14.

2. Graphite Packing

Within the temperature range of 200℃ to 450℃, graphite packing is the preferred packing material. Graphite packing has characteristics of high-temperature resistance, self-lubrication, and low friction coefficient, which can meet the sealing requirements under high-temperature conditions. According to different applications, various categories of graphite packing have been developed. For example, under 250℃ and low-pressure conditions, expanded graphite packing is a suitable choice; while under medium and high-pressure conditions, reinforced graphite packing or a combination of both can be used.

3. Expanded Graphite Packing

Expanded graphite packing, also known as flexible graphite packing, is braided with flexible graphite yarn through a core-spun process. This material has good self-lubrication, thermal conductivity, small friction coefficient, strong universality, good flexibility, and high strength, and also plays a protective role on the shaft rod. Its maximum service temperature can reach 600℃, maximum service pressure is 20MPa, and the applicable pH range is 0–14.

4. Reinforced Graphite Packing

Reinforced graphite packing is based on expanded graphite packing and is reinforced by adding glass fiber, copper wire, stainless steel wire, nickel wire, Inconel wire, and other materials. This material not only possesses all the characteristics of expanded graphite but also has strong universality, good flexibility, and high strength. When used in combination with ordinary braided packing, it is one of the effective sealing components to solve the sealing problems of high temperature and high pressure. Its maximum service temperature is 550℃, maximum service pressure is 32MPa, and the applicable pH range is 0–14.

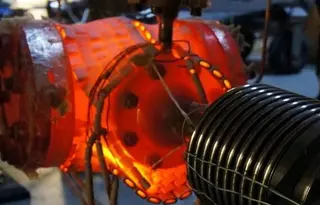

Challenges Faced by Sealing Rings in High-Temperature Environments

High-temperature environments pose severe challenges to the performance and lifespan of sealing rings. The main problems faced by sealing rings under high-temperature conditions are as follows.

1. Material Melting or Decomposition

Some materials melt or decompose at high temperatures, causing sealing failure. For example, certain organic materials age rapidly at high temperatures and lose their sealing properties.

2. Thermal Expansion and Contraction

High temperature causes sealing rings to expand, leading to leakage or failure; when the temperature drops, the sealing rings may shrink excessively, resulting in over-tightening or cracking. This thermal expansion and contraction phenomenon puts high demands on the materials and design of sealing rings.

3. Influence of High-Pressure Medium

In high-temperature environments, the high pressure of the medium forces the sealing ring to be extruded, easily causing plastic deformation or leakage. Therefore, sealing rings need to have sufficient strength and extrusion resistance.

4. Chemical Corrosion

Some high-temperature media are highly corrosive and can chemically corrode the sealing ring material, leading to loss of sealing performance. Therefore, selecting corrosion-resistant materials is key to ensuring the normal operation of sealing rings in high-temperature environments.

Safety Requirements of High-Temperature Valve Sealing Rings

To ensure the safe operation of high-temperature valve systems, sealing rings must meet the following safety requirements.

1. High-Temperature Resistance

High-temperature valve sealing rings should have good high-temperature resistance, maintaining stable physical and chemical properties in high-temperature environments. The sealing ring material should have a high melting point and heat resistance to ensure it does not melt, decompose, or fail.

2. Strength and Extrusion Resistance

Sealing rings should have sufficient strength and extrusion resistance to withstand the medium pressure and extrusion force in high-temperature environments. At the same time, they should also have certain creep resistance to prevent leakage caused by medium extrusion.

3. Chemical Stability

High-temperature valve sealing rings should have good chemical stability and be able to withstand chemical corrosion of high-temperature media. Material selection should consider the corrosiveness and chemical composition of the medium to ensure that the sealing ring does not fail due to chemical reactions.

4. Sealing Performance

High-temperature valve sealing rings must provide excellent sealing performance to prevent fluid leakage or seepage. Any leakage may cause catastrophic consequences, including equipment damage, casualties, and environmental pollution. Therefore, sealing rings must completely seal valves to ensure that fluids do not leak under high-temperature conditions.

Material Selection for High-Temperature Valve Sealing Rings

Choosing suitable materials is crucial for high-temperature valve sealing rings. Common material options include:

1. PTFE (Polytetrafluoroethylene)

PTFE has good chemical resistance and high-temperature performance, maintaining stable sealing effects at high temperatures. It is suitable for a variety of media, including corrosive media such as strong acids and alkalis.

2. Carbon Fiber

Carbon fiber has high strength and wear resistance in high-temperature environments, suitable for sealing requirements under high-temperature and high-pressure conditions. The high-temperature performance of carbon fiber makes it an ideal material for high-temperature valve sealing.

3. Metal Materials

Certain metal materials, such as stainless steel and nickel-based alloys, have good high-temperature and corrosion resistance, suitable for sealing requirements under extreme high-temperature and corrosive medium conditions. These metal materials not only withstand high temperatures but also resist chemical corrosion, ensuring the long-term stable operation of sealing rings.

Design and Installation of High-Temperature Valve Sealing Rings

In addition to material selection, the design and installation of sealing rings are also important factors in ensuring the safety of high-temperature valve systems. Reasonable sealing ring geometry, preload, and contact area can improve sealing performance. In addition, correct installation methods and tightening force are also key to ensuring that sealing rings operate normally in high-temperature environments.

1. Sealing Ring Design

The design of sealing rings should consider thermal expansion and contraction in high-temperature environments. Reasonable geometry can reduce sealing failure caused by thermal expansion and contraction. At the same time, the preload and contact area of the sealing ring should also be optimized according to actual working conditions to ensure sealing performance.

2. Installation Method

Correct installation method is key to ensuring the normal operation of sealing rings. During installation, the sealing ring’s position should be accurate to avoid sealing failure caused by improper installation. At the same time, the control of tightening force is also very important: excessive tightening force may cause sealing ring damage, while insufficient tightening force cannot ensure sealing effectiveness.

Selection of Packing for Special Working Conditions

In actual production, other types of packing developed for special working conditions are also encountered. For example, aramid fiber packing has good chemical resistance and is suitable for sealing requirements of high-load rotating shafts. The development and application of these special materials provide more options for high-temperature valve sealing.

Conclusion

High-temperature valve sealing is a complex technical issue involving material selection, sealing structure design, and installation. By reasonably selecting sealing materials and structures, and optimizing design and installation processes, the sealing performance of high-temperature valves can be effectively improved, ensuring the smooth progress of industrial production. It is hoped that the introduction in this article can help readers better understand and address the challenges of high-temperature valve sealing, providing strong guarantees for the safe operation of industrial production.

Send your message to this supplier

Related Articles from the Supplier

High-Temperature Ball Valves Material Selection

- Dec 17, 2025

How Does a High Performance Butterfly Valve Work

- Dec 14, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/high-temperature-valve-sealing-technology-and-challenges.html