Guide to V-Port Ball Valves: Structure, Function & Selection

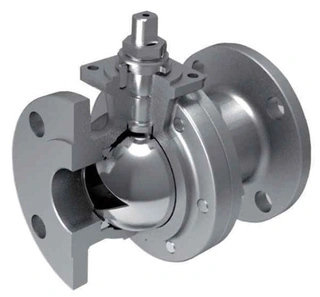

V-Port Ball Valve is an important member of the ball valve family. Its defining feature lies in the design of the closing element, a hemispherical ball with a V-shaped opening. This V-shaped notch has a sharp edge that creates a wiping action between sealing surfaces as the ball rotates, generating a strong cutting force on the medium.

The V-shaped opening of the ball works together with the valve seat flow passage to form a fan-shaped area. As the ball rotates, the cross-sectional area of this fan-shaped region changes accordingly, enabling precise regulation of the medium flow rate. Therefore, the V-port ball valve is essentially a quarter-turn control valve.

In terms of sealing performance, the V-port ball valve offers the same excellent sealing capability as conventional ball valves. However, its uniqueness lies in combining both throttling and on-off functions. When paired with pneumatic or electric actuators, it can be widely applied in industrial automatic control systems.

Structural Features of V-Port Ball Valves

The performance advantages of V-port ball valves stem from their scientific structural design. As a trunnion-mounted, single-seat sealed ball valve, it retains the strengths of traditional ball valves while being specifically optimized for control performance. The main structural features are as follows:

1. Valve Body Structure

The V-port ball valve belongs to the trunnion-mounted category and adopts a single-seat sealing design. Both wafer-type and flanged V-port ball valves typically use an integral side-mounted body structure. This configuration provides high rigidity, minimizes deformation and external leakage, and ensures long-term stable operation.

Self-lubricating upper and lower bearings are installed inside the valve body. These bearings provide a large contact area with the stem, high load-bearing capacity, and a low friction coefficient. This design directly reduces operating torque, making control easier and more flexible.

2. Valve Core Design

The valve core design distinguishes the V-port ball valve from ordinary ball valves. The core consists of a ball with a V-shaped notch that mates with the valve seat. By rotating the ball to adjust the angle of the V-shaped opening, the flow area of the fluid is controlled, enabling precise flow regulation.

This design provides an equal-percentage flow characteristic with a rangeability of up to 100:1. As a result, the valve can achieve fine control over a wide operating range, making it ideal for applications requiring accurate flow regulation.

3. Sealing Methods

The valve seat of a V-port ball valve can be selected based on the medium and operating conditions, typically offering either metal hard sealing or PTFE soft sealing:

Metal Hard Seal: The sealing surface is overlaid with hard alloy, while the ball surface undergoes hard chrome plating, spray welding, or ion nitriding treatment. These processes enhance service life and improve temperature resistance, making the valve suitable for high-temperature and high-pressure conditions.

PTFE Soft Seal: PTFE or reinforced PTFE seats provide excellent sealing and corrosion resistance with broad applicability, making them suitable for general operating conditions and corrosive media.

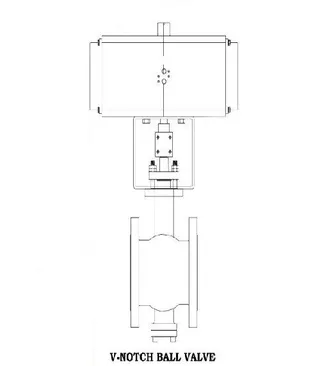

4. Actuation Mechanisms

V-port ball valves are commonly equipped with pneumatic or electric actuators. Pneumatic actuators use a piston cylinder and crank-arm conversion structure, delivering high output torque in a compact size. They feature fully sealed waterproof designs with high protection ratings. The cylinder body has a mirror finish and operates with oil-free lubrication, resulting in low friction, corrosion resistance, durability, and reliability. All transmission bearings use boundary self-lubricating technology to ensure minimal wear on the drive shaft.

Electric actuators regulate flow and other parameters by adjusting the rotation angle of the valve core (0–90°) through a 4–20 mA input signal. This control method is accurate and reliable, while the actuators themselves are compact and lightweight.

Working Principle of V-Port Ball Valves

The working principle is based on rotating the ball to control the opening and closing of the flow passage as well as the degree of opening.

When the actuator drives the valve stem to rotate, the V-shaped ball turns accordingly. The V-notch gradually aligns with or moves away from the valve seat channel, thereby changing the area available for medium flow. When fully aligned, the valve is completely open with maximum flow; when fully offset, the valve is closed, cutting off the medium.

A key advantage of this design is stable flow control even at small openings. Traditional valves often experience vibration and erosion under low-opening conditions, but the V-shaped notch effectively prevents these issues.

Additionally, the shearing force between the V-notch and the valve seat, combined with the smooth and streamlined internal flow path, prevents medium accumulation within the cavity. This makes V-port ball valves suitable not only for liquids but also for media containing fibers and solid particles.

Core Advantages of V-Port Ball Valves

- Excellent Control Performance: V-port ball valves provide some of the best control performance among ball valves. With equal-percentage flow characteristics and rangeability reaching 100:1 (and up to 300:1 for some pneumatic models), they deliver precise control across a broad operating range.

- Strong Shearing Capability: The shearing action between the V-notch and the metal seat makes the valve particularly suitable for media containing fibers, fine solid particles, or slurries. This function cuts through impurities and provides a self-cleaning effect, preventing valve blockage.

- High Flow Capacity: Thanks to their streamlined profile and full right-angle rotary control characteristics, these valves offer high volumetric capacity, large flow rates, and low resistance. Smaller, more economical valve sizes can often be used, reducing procurement costs.

- Simple and Reliable Structure: Compact, lightweight, easy to install, and simple to maintain, the integral valve body is unaffected by pipeline pressure and helps prevent leakage. With long service life and minimal maintenance requirements, reliability is ensured.

- High Cost Performance: The lightweight body and low stem torque allow for smaller actuator specifications compared with other control valves, resulting in superior cost performance. Special V-notch machining on small-diameter trims also enables precise low Cv control.

Application Scenarios of V-Port Ball Valves

V-port ball valves are widely used across multiple industrial sectors, including:

- Petrochemical Industry: Commonly used to control catalyst feed lines, their precise regulation and reliable sealing help ensure stability and safety in chemical production processes.

- Fine Chemical Industry: With high requirements for flow accuracy, the equal-percentage characteristic and wide rangeability make V-port ball valves an ideal choice for process control.

- Pulp and Paper Industry: Used to regulate pulp flow, the valve's shearing action effectively handles fibers, prevents clogging, and ensures continuous production.

- Water Treatment Industry: In wastewater treatment plants, V-port ball valves enable precise chemical dosing, ensuring reliable treatment performance.

- Pharmaceutical and Food & Beverage Industries: Sanitary designs and dependable sealing performance allow these valves to meet strict fluid control standards.

Key Selection Considerations for V-Port Ball Valves

Selecting the appropriate V-port ball valve requires following specific steps:

- Determine Pipeline Parameters: Identify pipeline diameter, required valve size, and connection type. Operating temperature and pressure must also be understood, as these directly affect material selection.

- Define Performance Parameters: Establish key parameters such as flow capacity, allowable resistance, and seat bore size. Incorrect parameter selection can significantly reduce control effectiveness.

- Choose Materials: Select materials based on operating temperature and medium characteristics. High-temperature conditions require metal hard seals and heat-resistant materials; corrosive media demand corrosion-resistant materials; general applications can use PTFE soft seals.

- Select the Actuator: Choose pneumatic actuators for applications requiring fast response and explosion-proof performance, and electric actuators for precise control and remote monitoring.

- Compare Suppliers: Avoid rushing the purchase. Understand current market offerings and evaluate performance differences. Contact multiple manufacturers for catalogs and technical data, and select products with the best cost-performance ratio.

Difference Between V-Port Ball Valves and Conventional Ball Valves

Although both operate with a 90-degree rotation, significant differences exist:

- Conventional Ball Valves: Feature a spherical closure element with a circular bore through its axis. They are primarily used for shutoff, distribution, and changing flow direction, making them most suitable as on-off valves.

- V-Port Ball Valves: Use a hemispherical closure with a V-shaped notch. In addition to on-off capability, they provide throttling and flow control. The shearing action allows them to handle fiber-containing and particulate media—tasks that conventional ball valves often struggle to perform.

Conclusion

The V-port ball valve is a powerful control component that perfectly combines the shutoff function of a ball valve with the flow regulation capability of a control valve. Its V-notch design enables precise flow adjustment and strong shearing performance, leading to widespread use in petrochemical, pulp and paper, water treatment, and many other industries.

When selecting a valve, it is essential to consider pipeline parameters, medium characteristics, operating conditions, and control requirements to determine the appropriate size, material, sealing method, and actuator. Comparing multiple suppliers and choosing reputable manufacturers with mature technologies will help ensure optimal performance in industrial automatic control systems.

As industrial automation continues to advance, the application scope of V-port ball valves will expand further. With their simple structure, reliable performance, and high cost-effectiveness, they represent an ideal control component for fluid pipeline systems.

Send your message to this supplier

Related Articles from the Supplier

Guide to Key Steps of Safety Valve Adjustment

- Oct 09, 2025

Guide to Valve Performance and Selection

- Oct 10, 2025

Guide to Valve Electric Actuator Selection

- Nov 05, 2025

Guide to Diaphragm Pump Material Selection

- Dec 19, 2025

Guide to Industrial Valve Pressure Testing

- Jan 14, 2026

Related Articles from China Manufacturers

Guide to V-Port Ball Valve Selection

- Jan 09, 2026

A Guide to Selecting Electric V-Type Ball Valves

- Aug 22, 2025

Guide to Liquid Die Forging Technology

- May 20, 2025

Guide to Nickel-Based Alloy Open Die Forging

- Dec 09, 2025

Guide to Multi-Directional Die Forging Technology

- Feb 04, 2026

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/guide-to-v-port-ball-valves-structure-function-selection.html