Guide to Industrial Valve Pressure Testing

In the industrial sector, valves are indispensable fluid control devices and pressure-retaining components. They are widely used in various piping systems to regulate the flow, pressure, and direction of fluids. To ensure the safety and reliability of valves in actual service, pressure testing has become one of the most important performance verification methods for industrial valves. This article provides a comprehensive introduction to industrial valve pressure testing, including test types, methods, applicable standards, and key considerations in practical operation.

Importance of Industrial Valve Pressure Testing

Pressure testing of industrial valves is a critical step in verifying that a valve can withstand the specified pressure while maintaining adequate sealing performance during service. Through pressure testing, the pressure resistance and sealing integrity of key components, such as the valve body, bonnet, and sealing pairs, can be evaluated, ensuring safe and reliable operation under various working conditions.

If a valve fails to meet the requirements of relevant standards during pressure testing, problems such as leakage or structural damage may occur in actual operation, potentially leading to serious safety incidents. Therefore, pressure testing is an essential quality assurance measure prior to valve delivery and use.

Common Types of Industrial Valve Pressure Tests

Before examining the details of industrial valve pressure testing, it is important to understand the most common test types. Each type serves a specific purpose and employs distinct methods. Together, they form a complete valve performance testing system that allows a comprehensive assessment of valve safety and reliability under real operating conditions.

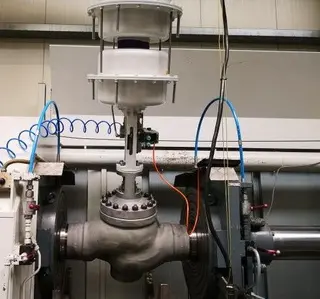

1. Shell Test

The shell test is a pressure test performed on the complete valve pressure boundary formed by the valve body, bonnet, and their connections. Its primary purpose is to verify the pressure resistance and structural integrity of the valve shell, as well as its freedom from leakage. The shell test is mandatory for every valve prior to leaving the factory, ensuring that the valve will not leak or suffer structural damage under the specified pressure.

Shell Test Procedure and Steps

- Preparation: Seal the inlet and outlet of the valve, tighten the packing gland, and place the closure member in a partially open position.

- Pressurization: Fill the valve cavity with the test medium (typically water or air) and gradually increase the pressure to the specified test pressure. For check valves, pressurization should be applied from the inlet side.

- Pressure Holding and Inspection: After reaching the specified holding time, inspect the shell, including the packing box and the body-to-bonnet joint, for any leakage. During the holding period, the test pressure must remain constant, and no external force that could affect the test results may be applied to the valve.

2. Seat (Seal) Test

The seat test is conducted to evaluate the sealing performance of the sealing pairs formed by the closure member and the valve body. Prior to the test, oil or grease should be removed from the sealing surfaces, although a thin protective film with a viscosity not exceeding that of kerosene is permitted. For valves that rely on grease sealing, the specified grease may be applied as required.

Seat Test Procedure and Steps

- Preparation: After completion of the shell test, conduct the seat test. The valve should be closed in the manner specified by the design.

- Pressurization: According to the valve type and applicable standard, apply the test medium to the sealing pair and gradually increase the pressure to the specified test value.

- Sealing Inspection: During the specified pressure-holding time, inspect the sealing performance of the sealing pair to ensure that there is no visible leakage.

3. Backseat Test

The backseat test is used to verify the sealing performance between the valve stem and the bonnet. All valves that are designed with a backseat sealing requirement must undergo this test. The backseat test may be performed prior to the shell test.

Backseat Test Procedure and Steps

- Preparation: Seal the inlet and outlet of the valve, loosen the packing gland, and place the valve in the fully open position.

- Pressurization: Fill the valve cavity with the test medium and gradually raise the pressure to the specified test pressure.

- Sealing Inspection: During the specified holding time, inspect the backseat sealing performance to ensure that there is no visible leakage.

Standards for Industrial Valve Pressure Testing

At present, several standards are commonly used for industrial valve pressure testing, including:

- API 598:2004 – Valve Inspection and Testing

- BS EN 12266:2003 – Industrial Valves — Testing of Valves

- ISO 5208:1993 – Industrial Valves — Pressure Testing of Valves

These standards specify detailed requirements for valve pressure testing, including test pressure, holding time, test medium, and test methods. In addition, certain countries have their own valve testing standards that are applied to varying degrees. For valves with special structures or specific applications, manufacturers or end users may establish additional inspection and testing specifications and require their implementation.

Test Pressure and Pressure-Holding Time

Test pressure and pressure-holding time are critical parameters that must be strictly observed during pressure testing. Test pressure is usually determined based on the valve type, size, test item, and the maximum allowable working pressure of the pressure-containing material, following a defined proportional relationship.

In practice, however, insufficient pressure-holding time is a common issue, particularly under tight production schedules and inadequate supervision. This can lead to inaccurate test results and compromise the safety and reliability of the valve.

Test Equipment and Operational Requirements

Test equipment and facilities should, as far as possible, comply with the requirements of relevant standards to ensure accuracy and reliability. During testing, no external force that could influence the test results should be applied to the valve.

The selection of the test medium is also critical. Water or air is typically used, although other suitable liquids or gases may be applied in special cases. The temperature of the test medium should be controlled within the range of 5–40 °C to ensure stable and consistent test conditions.

Key Considerations in Practical Operation

In industrial valve pressure testing, operational details and precautions play a decisive role in the accuracy and reliability of test results, as well as in the safety of personnel. The following points deserve particular attention:

1. Selection and Handling of Test Media

- Liquid Media: When liquid media such as water or kerosene are used, air within the valve cavity should be removed as thoroughly as possible to ensure accurate and stable test pressure.

- Gaseous Media: When gaseous media such as air are used, appropriate safety precautions must be taken to prevent accidents caused by gas leakage.

2. Inspection and Documentation During Testing

- Inspection Items: During testing, carefully inspect the valve shell, sealing pairs, and other critical components for leakage or structural damage. For shell tests, special attention should be paid to the packing box and body-to-bonnet joints.

- Record Keeping: Test results should be recorded in detail, including test pressure, holding time, test medium, and inspection findings. These records are valuable for evaluating valve performance and serve as an important basis for product quality traceability.

3. Post-Test Handling

- Coating Treatment: Before completion of the shell test, painting or other leakage-preventing coatings are not permitted. However, non-sealing chemical rust-prevention treatments and lining of lined valves are allowed. For stock valves that have already been painted, removal of the coating is not required if the user requests re-testing.

- Leakage Handling: If leakage is detected during testing, the test must be stopped immediately. The cause of leakage should be identified and corrected before re-testing.

Test Methods for Different Valve Types

Due to the wide variety of valve types, each with its own structure and operating principle, pressure testing methods differ accordingly. Understanding these differences is essential to ensure accurate and effective testing.

1. Gate, Ball & Plug Valves

Pressurization Method: Seal both ends of the valve, keep the closure member slightly open, fill the body cavity with the test medium, and gradually increase pressure to the test value. Close the closure member and release pressure at one end; repeat the same procedure for the other end.

Notes: For valves with two independent sealing pairs, the test medium may also be introduced into the cavity between the two sealing pairs and pressurized.

2. Globe & Diaphragm Valves

Pressurization Direction: Pressure should be applied in the direction most unfavorable to seat sealing. For example, in globe valves and angle-type diaphragm valves, the medium should be introduced in the direction that tends to open the disc.

Inspection Focus: Particular attention should be paid to the sealing performance of the valve seat to ensure no visible leakage at the specified test pressure.

3. Butterfly Valves

Pressurization Direction: Pressure should be applied in the direction most unfavorable to sealing. For butterfly valves with symmetrical seats, pressurization may be applied in either direction.

Inspection Method: Verify the sealing performance of the butterfly valve sealing pair at the specified test pressure, ensuring no visible leakage.

4. Check Valves

Pressurization Direction: Pressure should be applied in the direction that causes the disc to close. However, for valves with a specified flow direction, pressurization should follow the designated flow direction (except for check valves).

Inspection Focus: Emphasis should be placed on verifying the sealing performance of the check valve under the specified test pressure.

Conclusion

Industrial valve pressure testing is a vital process for ensuring valve safety and reliability. Through shell tests, seat tests, and backseat tests, the pressure resistance and sealing performance of valves can be comprehensively evaluated. Strict adherence to relevant standards and operating procedures, appropriate selection of test media, and careful control of test conditions are key to ensuring accurate and reliable results.

It is hoped that this article will help readers better understand and apply industrial valve pressure testing practices, thereby improving valve quality and operational safety. In practical applications, manufacturers and users are encouraged to closely monitor updates and changes in relevant standards and to adjust testing methods and equipment accordingly to meet evolving industrial demands. At the same time, strengthening supervision and management of the testing process is an important guarantee for improving the overall quality of industrial valves.

Send your message to this supplier

Related Articles from the Supplier

Guide to Industrial Valve Pressure Testing

- Jan 14, 2026

Guide to Key Steps of Safety Valve Adjustment

- Oct 09, 2025

Guide to Valve Performance and Selection

- Oct 10, 2025

Guide to Valve Electric Actuator Selection

- Nov 05, 2025

Guide to Diaphragm Pump Material Selection

- Dec 19, 2025

Guide to Soft Seal Butterfly Valves

- Jan 16, 2026

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Zhejiang Kosen Valve Co., Ltd.

- https://www.kosenvalve.com/

- Business Type: Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.kosenvalve.com/media-hub/guide-to-industrial-valve-pressure-testing.html