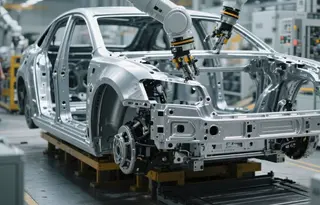

Integrated Die-Casting Aluminum Alloys in Automotive Manufacturing

In the automotive manufacturing sector, integrated die-casting technology is gradually becoming a hot topic in the industry. This technology not only changes the traditional body production process but also brings new possibilities for the lightweight and high-performance of automobiles. However, to achieve the successful application of integrated die-casting, the performance of aluminum alloy materials is crucial. This article will delve into the performance requirements of integrated die-casting aluminum alloys, the material characteristics, and the key points of the die-casting process, helping readers better understand this cutting-edge technology.

Performance Requirements of Integrated Die-Casting Aluminum Alloys

Integrated die-casting aluminum alloys are a key technology in the automotive manufacturing field, and their performance requirements directly determine the quality of parts and production efficiency. To meet the manufacturing needs of large and complex structural components, this material must possess a series of unique performance characteristics.

1. Thermoplastic Rheological Properties

Integrated die-casting parts typically have characteristics such as large size, thin walls, and complex structures. This requires aluminum alloy materials to have good thermoplastic rheological properties when the overheating temperature is not higher than the liquid-solid phase line temperature. This property ensures that the material can flow smoothly in complex cavities, forming a good casting surface and avoiding shrinkage defects caused by insufficient filling. For example, in the manufacturing of large body structural components, good thermoplastic rheological properties allow the material to better fill every corner of the mold, ensuring the integrity and surface quality of the part.

2. Low Linear Shrinkage Rate

Linear shrinkage rate refers to the degree of volume reduction of the material during the cooling process. For integrated die-casting parts, a low linear shrinkage rate is crucial as it can prevent cracks and deformation during the die-casting process, thereby maintaining high dimensional accuracy. For example, in the production of high-precision body structural components, if the linear shrinkage rate is too high, the parts may have dimensional deviations after cooling, affecting subsequent assembly and use. Therefore, selecting aluminum alloy materials with a low linear shrinkage rate can significantly improve the quality and reliability of die-casting parts.

3. Narrow Solidification Temperature Range

The solidification temperature range refers to the temperature range in which the material transitions from a liquid to a solid state. Integrated die-casting aluminum alloys need to have a narrow solidification temperature range to achieve rapid simultaneous solidification. This helps reduce the formation of internal shrinkage cavities and other defects. For example, in the manufacturing of large integrated die-casting parts, rapid simultaneous solidification can ensure uniform internal structure of the part, avoiding internal defects caused by inconsistent solidification speeds. A narrow solidification temperature range not only improves the quality of the part but also shortens the production cycle and increases production efficiency.

4. Good Casting (Mold) Interface Properties

During the die-casting process, the interaction between aluminum alloy materials and the die-casting mold has a significant impact on the quality of the part. Integrated die-casting aluminum alloys need to have minimal chemical reaction with the die-casting mold and low affinity to reduce mold sticking and mutual alloying. For example, if the affinity between the material and the mold is too high, it may cause mold sticking, not only affecting the surface quality of the part but also increasing mold wear. Therefore, good casting (mold) interface properties are one of the key factors to ensure the smooth progress of the die-casting process.

Characteristics of Heat-Treatment-Free Aluminum Alloys

Heat-treatment-free aluminum alloys, as the core material of integrated die-casting technology, have brought significant changes to automotive manufacturing, not only improving production efficiency but also significantly reducing costs and environmental impact.

1. Necessity of Heat-Treatment-Free

For traditional aluminum alloys, heat treatment is an essential means to ensure the mechanical properties of parts. However, the heat treatment process can easily cause surface defects and dimensional deformation of parts, which will inevitably increase the scrap rate for large integrated parts and pose significant cost risks. For example, in the production of large body structural components, surface cracks and dimensional deformation that may occur during the heat treatment process can lead to a large number of parts being scrapped, increasing production costs. Therefore, the development of special heat-treatment-free aluminum alloys has become a key to integrated die-casting technology.

2. Mechanical Properties of Heat-Treatment-Free Aluminum Alloys

Heat-treatment-free aluminum alloys need to ensure good mechanical properties after material forming without undergoing heat treatment. The structural design of parts is based on the strength of the material, and the higher the material strength, the more significant the weight reduction. For example, in the design of body structural components, high-strength heat-treatment-free aluminum alloys can achieve lighter weight while meeting the requirements for collision and fatigue performance. Integrated die-casting structural components require the material to have high strength and plasticity in the as-cast state, which poses higher requirements for the control of the material's microstructure.

3. Importance of Microstructure Control

The characteristic of heat-treatment-free materials is the elimination of the heat treatment process, so the mechanical properties can only be achieved through the microstructure formed during the casting process. Currently, the key to controlling the microstructure of heat-treatment-free materials lies in the control of eutectic structures. Aluminum-silicon alloys focus on controlling the morphology and size of eutectic silicon, while aluminum-magnesium-silicon alloys focus on controlling the morphology and size of magnesium disilicide. For example, by adding rare earth elements such as lanthanum (La) and gadolinium (Gd) as modifiers, the morphology and size of eutectic structures can be effectively controlled, thereby improving the strength and plasticity of the material. However, in actual production, the effectiveness of modifiers may decrease over time, which poses a challenge to continuous production.

Key Aspects of Integrated Die-Casting Process

The integrated die-casting process is the core link in the manufacturing of high-quality aluminum alloy parts, and the precise control of process parameters directly affects the performance and production efficiency of the product.

1. Process Flow

The production process of integrated die-casting parts mainly includes melting, die-casting, grinding, X-ray and machining, and assembly. Compared with traditional body structural components such as shock towers and longitudinal beams, integrated die-casting parts omit the heat treatment (straightening) process. The die-casting process is the key link in the entire production process, and its process flow is as follows: spraying, mold closing, pouring, injection, holding pressure, mold opening, part removal, integrity inspection, cooling, trimming, and conveyor belt.

2. Process Parameter Control

Die-casting process parameters mainly include pressure, speed, time, temperature, and vacuum. The control of these parameters is crucial for the quality of integrated die-casting parts. For example, the casting pressure for air-tight products usually requires 80MPa, 60MPa for general products, while integrated die-casting products are all below 40MPa. This is because excessive pressure may lead to insufficient mold clamping force, thereby causing flash. The empty injection speed of the die-casting machine is generally required to be above 10m/s, the actual maximum speed of the punch is 6–8m/s, and the internal gate speed is 40–55m/s. The filling time is usually between 50–80ms. In terms of temperature, the aluminum melt temperature is 700–710℃, and the mold temperature is 220–280℃. Integrated die-casting has high requirements for mold thermal balance, and the vacuum degree is generally between 30–50mbar, with actual operations preferably below 30mbar.

3. Control of the Pouring Process

The pouring process of aluminum alloy has a significant impact on the mechanical properties of integrated die-casting parts. Pre-crystallization structures can significantly weaken the mechanical properties of integrated die-casting parts, so it is necessary to control pre-crystallization through means such as the temperature of the melt cup, barrel heating, and die-casting process. For example, during the pouring process, by precisely controlling the temperature and flow speed of the aluminum melt, the formation of pre-crystallization structures can be effectively reduced, thereby improving the mechanical properties of the part.

Application Prospects of Integrated Die-Casting Aluminum Alloys

With the development of automotive lightweighting and new energy vehicles, integrated die-casting aluminum alloys show broad application prospects. Their market demand and application fields are continuously expanding, driving the transformation of the automotive manufacturing industry.

1. Economy and Environmental Protection

With the establishment of the dual-carbon target, the application of recycled materials in the heat-treatment-free production process is increasingly attracting attention. Integrated die-casting aluminum alloys can tolerate high levels of elements and impurities, which not only ensures economy but also improves the performance of castings. For example, the use of recycled materials can significantly reduce production costs while reducing environmental impact. In addition, the use of heat-treatment-free aluminum alloys reduces the heat treatment process, further reducing energy consumption and carbon emissions.

2. Diversity of Connection Methods

Large integrated die-casting body structural components have different performance requirements in different parts, so different connection methods such as welding, SPR, and bonding may need to be adopted. Different connection methods also have different performance requirements for materials. For example, SPR requires materials to have higher toughness, while welding requires materials not to have defects such as porosity. Integrated die-casting aluminum alloys need to meet the requirements of these different connection methods to ensure the overall performance of the part.

3. Future Development Trends

Integrated die-casting technology is continuously driving the transformation of the automotive manufacturing industry. In the future, with the continuous progress of material science and process technology, the performance of integrated die-casting aluminum alloys will continue to improve, and the application scope will further expand. For example, by developing new types of heat-treatment-free aluminum alloy materials, the strength and plasticity of parts can be further improved while reducing production costs. In addition, with the development of intelligent manufacturing technology, the automation and intelligence level of the integrated die-casting process will also continue to improve, further increasing production efficiency and product quality.

Conclusion

Integrated die-casting aluminum alloys have broad application prospects in the automotive manufacturing field. Their good thermoplastic rheological properties, low linear shrinkage rate, narrow solidification temperature range, and good casting (mold) interface properties enable them to meet the production requirements of complex structural components. The development of heat-treatment-free aluminum alloys not only improves the mechanical properties of materials but also reduces production costs and environmental impact. The strict parameter control of the integrated die-casting process and the fine management of the pouring process ensure the high quality and high reliability of die-casting parts. With the continuous progress of technology, integrated die-casting aluminum alloys will play a more important role in future automotive manufacturing, providing strong support for the lightweight and high-performance of automobiles.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

Integrated Die Casting

- Sep 24, 2022

Rear Subframes Made by Integrated Die Casting

- Nov 30, 2022

The Trend of Integrated Die Casting

- Nov 30, 2022

Integrated Die-Cast

- Nov 25, 2024

Related Products Mentioned in the Article

Supplier Website

Source: https://www.forging-casting-stamping.com/integrated-die-casting-aluminum-alloys-in-automotive-manufacturing.html