2-Axis Servo Robot Arm for Plastic Injection Molding Machine

Key Specifications / Features

2-Axis Servo Robot Arm Supplier Supplies 2-Axis Servo Robot Arm, for Plastic Injection Molding Machine, Travel 600-800mm, IMM Range 50-250 Ton, AC Servo Motor.

Request a quote

Detail Information

Runma 2 axis 600-800 Series traversing robot arm is applicable to all types of horizontal injection machine ranging from 50 to 250 ton for products and sprues take-out.

Single stage or telescopic type vertical arm, with product arm and runner arm, for two plate or three plate mold products take out.

Y-, Z-axis driven by AC servo motor, can realize products stacking up on any points at Y, Z directions, can cut the runner by scissors driven by the cylinder.

Single stage or telescopic type vertical arm, with product arm and runner arm, for two plate or three plate mold products take out.

Y-, Z-axis driven by AC servo motor, can realize products stacking up on any points at Y, Z directions, can cut the runner by scissors driven by the cylinder.

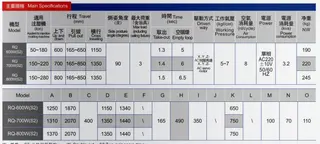

| Model | Applied to injection molding machine (ton) | Travel | Side posture angle (degree) | Max load (including fixture) | Time (sec) | Driven way | Working pressure (kgf/cm2) | Air consumption (nl/cycle) | Power | Power consumption | NW (kg) | |||

| up and down | pull out | cross traveling | take-out | empty loop | ||||||||||

| RQ-600ID(S2) | 50-180 | 600 | 165-650 | 1150 | 90 | 3 | 1.3 | 5 | x, y, z AC servo motor | 5-7 | 8 | AC220±10V 50/60HZ | 3.2 | 190 |

| RQ-700ID(S2) | 150-220 | 700 | 165-850 | 1350 | 1.4 | 6 | 220 | |||||||

| RQ-800ID(S2) | 150-280 | 800 | 165-850 | 1350 | 1.5 | 6.5 | 245 | |||||||

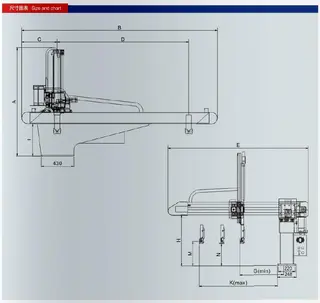

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O |

| RQ-600ID(S2) | 1250 | 1870 | 400 | 1150 | 1340 | \ | 165 | 490 | 350 | \ | 650 | \ | 100 | 70 | 110 |

| RQ-700ID(S2) | 1310 | 2070 | 1350 | 1440 | 750 | ||||||||||

| RQ-800ID(S2) | 1370 | 2070 | 1350 | 1440 | 750 |

Send your message to this supplier

FAQs

Yes, 3.2 certificates are available at an additional cost. We work with reputable third-party inspection agencies (TPI) such as BV, TUV, SGS, or LR, who will inspect the valves and issue signed certificates provided with the shipment.