- Products

- Industrial Parts

- Metallurgy, Chemicals, Rubber & Plastics

- Hardware

- Bags, Shoes & Accessories

- Packaging, Advertising & Office

- Electronics

- Home, Lights & Construction

- Apparel,Textiles & Accessories

- Machinery

- Agriculture & Food

- Tools

- Electrical Equipment, Components & Telecoms

- Auto & Transportation

- Gifts, Sports & Toys

- Health & Beauty

- Measurement & Analysis Instruments

- Suppliers

- News

- For Sale

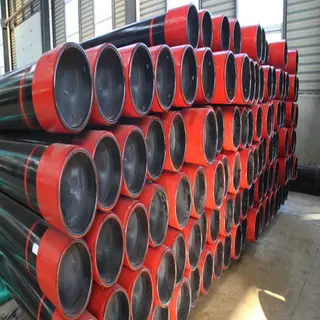

H40 Slotted Liners Screening Pipe, OD 60.3-508 MM

Key Specifications / Features

China H40 Slotted Liners Screening Pipe Supplier Offers H40 Slotted Liners Screening Pipe, N80, OD 2-3/8 - 20 Inch, WT 3.56-9.52 MM, Slotted≥0.07mm.

Request a quote

Detail Information

1. The screening pipe is processed by J55 or N80 petroleum casing body, which has high strength and is not easy to deform.

2. The verticality of the cutting edge is good, the cutting edge is smooth, without burrs, and the cutting edge is even.

3. Large flow area, 300 slits, 1.5m for 2-7/8 Inch screen tube, 72 flow area per cubic centimeter, which is 2.4 times larger than the flow area of the same size tubing. It is good for liquid flow.

4. Its advantages are more obvious in inclined and horizontal wells.

5. The whole is anti-corrosive treated, and a dense protective layer is formed on each surface of the screen pipe, which improves the corrosion resistance and wear resistance of the screen pipe, and can effectively extend the life of its underground work.

6. Suitable for sand control in sand production wells with a sand production diameter larger than 0.3mm.

7. Simple operation, easy to use, large inner diameter, easy to configure the string.

2. The verticality of the cutting edge is good, the cutting edge is smooth, without burrs, and the cutting edge is even.

3. Large flow area, 300 slits, 1.5m for 2-7/8 Inch screen tube, 72 flow area per cubic centimeter, which is 2.4 times larger than the flow area of the same size tubing. It is good for liquid flow.

4. Its advantages are more obvious in inclined and horizontal wells.

5. The whole is anti-corrosive treated, and a dense protective layer is formed on each surface of the screen pipe, which improves the corrosion resistance and wear resistance of the screen pipe, and can effectively extend the life of its underground work.

6. Suitable for sand control in sand production wells with a sand production diameter larger than 0.3mm.

7. Simple operation, easy to use, large inner diameter, easy to configure the string.

| Slotted Liner Products | |

| Outside Diameter | 60.3MM-508 MM (2-3/8 inch-20 inch). |

| Wall-Thickness | 3.56MM-9.52MM (4PPF-133PPF). |

| Standard | API 5CT, GB, ISO 11960, GOST. |

| Type of Hole | Rectangular, Square, Trapezoid, etc. |

| Size of Hole | Slotted: ≥0.07mm. |

| Steel Grade | H40, J55, K55, N80-1, N80-Q, L80-1, L80-9Cr, L80-13Cr, P110, Q125, etc. |

| Type | Seamless Pipe, ERW. |

Send your message to this supplier

FAQs

Similar Products

Related Searches

Products you might also like

Categories

Supplier Website

- www.china-die-casting.com

- www.valvesforged.com

- www.plastic-mold.com

- www.suppliesfarm.com

- www.floatingsolarmounting.com

- www.ldpepipe.com

- www.mfrsvalve.com

- www.stuffedtoyschina.com

- www.die-castings.com

- www.pipessteel.com

- www.facemaskssupplier.com

- www.huifengpharma.cn

- www.steel-pipes.com

- www.solarpvpanel.com

- www.bottlingfilling.com

- www.mfrsbidet.com

- www.wheel-excavators.com

- www.chinavalvesflange.com

- www.fabtank.com

- genset-generator-suppliers.com

- www.asev.net

- www.moldingworld.com

- plastic-locker.com

- ev-charger-china.com

- www.kellyvalve.com

- www.chinageneratorsets.com

- www.forgevalves.com

- www.valvepackingsealkits.com

- www.partsforged.com

- www.dcacevchargers.com

Source: https://www.pipessteel.com/h40-slotted-liners-screening-pipe-od-60-3-508-mm.html

Copyright © 2015-2026 China Manufacturers, CNMFRS.COM, All rights reserved.

谷歌优化(Google SEO)