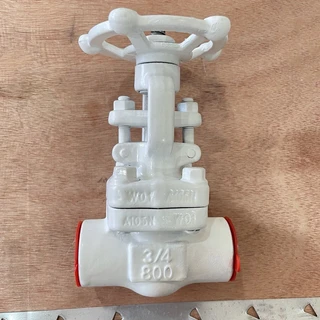

Rising Stem Gate Valves, API 602, A105N, 3/4 Inch, CL800, SW

Key Specifications / Features

The Low-E Gate Valve is a high-quality rising stem gate valve designed for demanding industrial applications. Manufactured to stringent API 602 and ASTM A105N standards, this forged carbon steel valve features a robust 3/4-inch diameter and a Class 800 LB pressure rating, ensuring exceptional durability and reliability. Equipped with a handwheel for easy operation and featuring socket weld (SW) ends for secure connections, this valve is ideal for critical systems requiring precise control and long-term performance.

Detail Information

Product Name: ASTM A105N Gate Valve, Rising Stem

Design Standard: API 602

Body Material: ASTM A105N

Size: 3/4 Inch, DN20

Pressure: Class 800 LB, PN130

Operation: Handwheel

End Connection: SW Ends

Face to Face Standard: MFG

Test & Inspection Standard: API 598

Certificates: TA-Luft, ISO 15848-1, API 622, ect

Product Range

Body Materials: ASTM A105, A105N, ASTM A182 F304/F304L, F316/F316L, F11, F22, F91, A350 LF2, etc

Gasket & Packing Material: Graphite/PTFE

Size Range: 1/2-2 Inch

End Connection: SW, BW, Flanged, NPT

Pressure Range: Class 150-2500 LB

Temperature Range: -29°C to 425°C

Medium: Water, Steam, Gas, etc.

The packing used in forged valves is the M800 series graphite packing,

with a graphite carbon content exceeding 99% and a sulfur content below 50 PPM.

The dynamic leakage rate, as tested according to API 622, is less than 12 PPM.

The static leakage rate is below 6 PPM.

All the gaskets used are low-emission gaskets certified by TÜV Rheinland TA-LUFT.

Type Test Report for 2-Inch Gate Valve

According to ISO 15848-1 at 400°C

Type Test Report for 1-Inch Globe Valve

According to ISO 15848-1 at 400°C

Type Test Report for 3/4-Inch Gate Valve

According to ISO 15848-1 at 400°C

The 0.5-inch forged steel gate valve in accordance with API 602 is tested for an ISO 15848-2 Class A leakage rate below 50 PPMV, using the M600 model low emission packing.

The 1-inch forged steel gate valve, in accordance with API 602, is tested for an ISO 15848-2 Class A leakage rate of less than 50 PPMV, using the M600 model low-emission packing.

The 1.5-inch forged steel globe valve, in accordance with API 602, is tested for an ISO 15848-2 Class A leakage rate of less than 50 PPMV, using the M800 model low-emission packing.

The API 624 test for a 2-inch forged steel gate valve in accordance with API 602 uses the M600 model low-emission packing.

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.