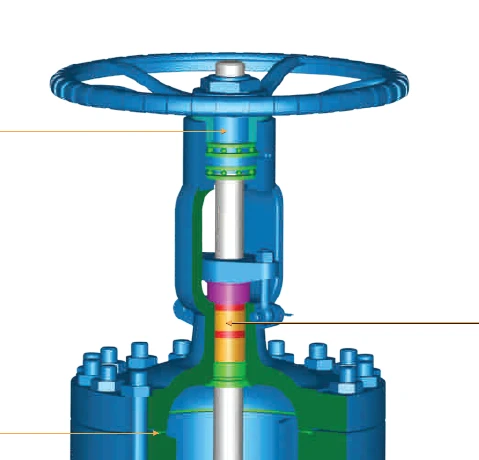

Y Type Pressure Sealed Check Valve, F304, 1-1/4 Inch, CL2500

Key Specifications / Features

This Y-type Pressure Sealed Check Valve is a high-pressure, compact solution engineered for reliable backflow prevention. Manufactured to API 602 and ASME B16.34 standards, it features a forged ASTM A182 F304 stainless steel body for excellent strength and corrosion resistance. Sized at 1-1/4 inch (DN32) with Class 2500 LB (PN420) pressure rating, and equipped with butt weld ends, this valve is ideal for critical applications in power plants, oil and gas systems, and high-pressure steam lines.

Detail Information

Product Name: Y Type Pressure Sealed Check Valve

Design Standard: API 602, ASME B16.34

Body Material: ASTM A182 F304

Size: 1-1/4 Inch, DN32

Pressure: Class 2500 LB, PN420

End Connection: BW

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Pressure Sealed Check Valves are engineered and manufactured in strict accordance with international standards such as API 602 and ASME B16.34. Designed to minimize flow resistance and pressure drop, these valves are suitable for horizontal installation only.

The seat ring is precision-lapped and screwed in to ensure a tight shutoff and long service life. The valve disc is precisely designed, accurately machined, and guided to enable reliable automatic shutoff at zero pressure. These check valves are compact, emission-compliant, and available in both swing and piston (lift) constructions for various industrial needs.

Technical Specifications

» Size Range: 1/2-2 Inch (Forged Items)

» Design Pressure: Class 900-2500 LB (PN160-PN420)

» Body Materials: Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, and other special alloys

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other custom options

» End Connections: SW (Socket Weld), FNPT, BW (Butt Weld), RF (Raised Face), RTJ (Ring Type Joint), Grooved

» Design & Manufacture Standards: ASME B16.34, API 602

» Face-to-Face Dimensions: ANSI B16.10

» Flanged Connections: ANSI B16.5

» Butt Weld Ends: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Testing & Inspection: API 598, API 6D

Product Features

» Effectively reduces water hammer during fluid flow, protecting pipelines and equipment from impact damage

» Available in bolted bonnet or welded bonnet construction for high-integrity sealing

» Optional swing-type or lift-type (piston) configurations

» Available in full port or reduced bore designs

Send your message to this supplier

FAQs

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.