Y Type Bellows Sealed Globe Valve, DIN 3356, EN 1.0619, DN50

Key Specifications / Features

Detail Information

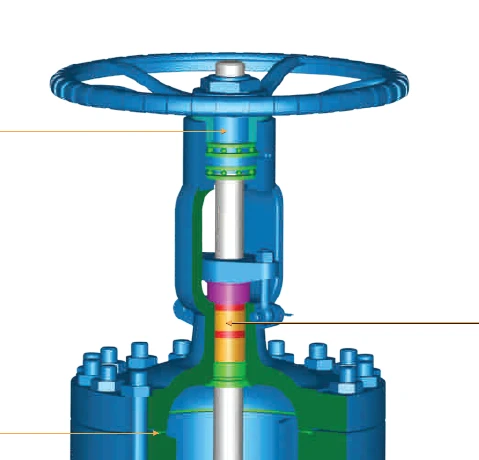

Product Name: Y Type Bellows Sealed Globe Valve

Design Standard: DIN 3356

Body Material: EN 1.0619

Size: DN50, 2 Inch

Pressure: PN40, Class 300 LB

End Connection: RF Flanged

Operation: Handwheel

The Bellows-Sealed Globe Valve incorporates advanced foreign technology, featuring a double bellows design welded to the valve stem for enhanced operational stability. This design prevents valve vibration caused by plug movement. At high temperatures, the stem remains isolated from the medium, ensuring zero leakage and maintaining long-term reliability. The valve is designed for durability, capable of enduring tens of thousands of cycles while maintaining strength and toughness.

The ergonomic handwheel ensures ease of operation and extended service life. This valve operates with a plug-shaped disc, featuring either a flat or conical sealing face, moving linearly along the fluid’s centerline. Due to minimal friction between sealing surfaces, it is highly durable, requires low opening height, and is easy to manufacture with compact dimensions, making it one of the most widely used globe valves.

Technical Specifications

» Nominal Diameter: 1/2–16 Inch, DN15–DN400

» Design Pressure: Class 150–600 LB, PN16–PN64

» Materials:

Body: 1.0619, GS-C25, ASTM A216 WCB, WCC, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M

Bellows: SS 304, SS 316, SS 316L, etc

» End Connection: Flanged, Welded, or Threaded Ends

» Operation: Handwheel, Bevel Gear, Electric, Pneumatic

» Design and Manufacture: DIN 3356

» Inspection and Testing: ISO 5208, EN 12266

» Flanged Ends Dimension: DIN 2543, DIN 2544, DIN 2545

» Butt-Welded Ends Dimension: EN 12627

» Face-to-Face and End-to-End: DIN 3202, EN 558-1, ISO 5752

» Pressure-Temperature Ratings: DIN 2401

» Test & Inspection: DIN 3230

» Medium: Water, Gas, Oil, etc

» Temperature Range: -29°C to 595°C

Product Features

» Reliable Design – Bellows-sealed globe valves feature a robust structure, reliable sealing, excellent performance, and an aesthetically refined appearance.

» Broad Material Availability – Available in various cast body and trim materials, offering a cost-effective solution for diverse process and steam systems.

» Enhanced Sealing Surface – Hard-faced with chromium alloy, ensuring wear resistance, corrosion resistance, and low friction for extended service life.

» Durable Stem – Quenched, tempered, and nitrided for superior corrosion and friction resistance.

» Optional Stem Position Indicator – Provides a clear visual status of valve operation for enhanced monitoring.

Send your message to this supplier

FAQs

OS&Y stands for Outside Screw and Yoke. This design places the threaded stem outside the valve body, with the yoke supporting the stem. It allows users to visually verify whether the valve is open or closed by observing the stem’s position.

OS&Y gate valves are commonly used in fire protection systems, including sprinklers, hydrants, and standpipes, due to their reliability and clear open/close indication.