Welded Bonnet Globe Valves, API 602, A105N, 2 IN, CL1500, SW

Key Specifications / Features

The Welded Bonnet Globe Valves Plant offers a high-quality API 602 Forged Globe Valve, specifically designed for demanding industrial applications. This valve features a robust Carbon Steel ASTM A105N construction, ensuring durability and reliability. With a 2-inch (DN50) size and a Class 1500 LB (PN250) pressure rating, it provides excellent flow control and pressure regulation. The socket weld ends facilitate secure and efficient connections, while the manual operation allows for precise control.

Detail Information

Product Name: Welded Bonnet Globe Valves

Design Standard: API 602

Body Material: ASTM A105N

Size: 2 Inch, DN50

Pressure: Class 1500 LB, PN250

End Connection: SW End

Operation: Manual

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Forged Steel Globe Valves are meticulously engineered and manufactured in strict adherence to international standards such as API 602, ASME B16.34, DIN 3202, or their equivalents. These valves are designed with a compact yet extremely robust construction, making them ideal for high-pressure and high-temperature applications. Key Features:

Solid CoCr Alloy Wedge (Optional): The optional solid CoCr alloy wedge ensures low friction and extended service life, enhancing the valve's performance and durability.

High Integrity Seal: The packing rings are precompressed to 4000 psi, providing a highly reliable seal that prevents leaks and maintains system integrity.

Welded Bonnet Valves: For welded bonnet valves, the bonnet is threaded in and torqued to an engineered torque value. The body-bonnet joint is then strength-welded, offering dual protection against leakage through the combination of threads, torque, and welding.

Fully Guided Wedge: The fully guided wedge design minimizes wear on the seating surfaces, ensuring consistent performance and longevity.

Optional Design Features: Available options include double packing, leak-off connections, live-loading capabilities, and a packing blowout mechanism for easy removal of old packing.

Technical Specification

» Size Range: 1/2-2 Inch (Forged Items)

» Temperature Range: -29°C to 595°C

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Forged Carbon Steel, Forged Alloy Steel, Forged Stainless Steel, Forged Duplex & Super Duplex Steel

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other special alloys

» Ends Connections: SW (Socket Weld), BW (Butt Weld), RTJ Flange

» Design & Manufacture Standards: ASME B16.34, API 602

» Face-to-Face (End-to-End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test & Inspection: API 598, API 6D

» Butt Weld End: ANSI B16.5

» Threaded Ends to ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

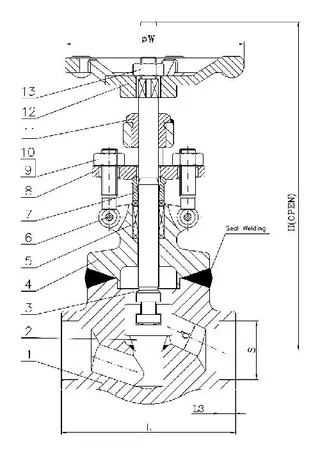

Structural Diagram

Product Features

» Superior Corrosion Resistance: The forged steel materials used in our valves undergo fine processing, resulting in excellent corrosion resistance. This makes our valves highly suitable for a wide range of corrosive media, thereby significantly extending their service life.

» Compact Design for Space Efficiency: Our forged steel globe valves are designed to be compact, with a smaller volume and reduced space occupation. This design not only makes them easy to install and use but also makes them particularly well-suited for applications where space is limited.