Stainless Steel Diaphragm Pump, DN10-DN125, Threaded Ends

Key Specifications / Features

Detail Information

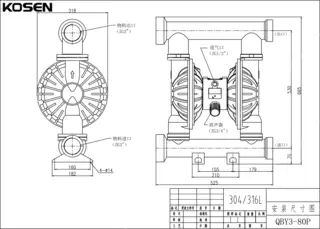

Product Name: Stainless Steel Diaphragm Pump, Threaded End

Port Size: 10-125 mm, DN10-DN125

Pump Material: Aluminum Alloy, Stainless Steel, Carbon Steel, Plastic

Connection: Threaded End

Diaphragm: VITON, PTFE, EPDM, NBR

Ball: PTFE, Stainless Steel, VITON, Ceramic

Seat: PTFE, Stainless Steel, VITON

Maximum Particle Diameter: 6 mm

Temperature: -20 to 150°C

Medium: Various Chemicals: Acids, Alkalis, Solvents, etc

The pneumatic diaphragm pump is the third generation of our pneumatic diaphragm pumps, offering reliable quality and a long service life. It features low noise, minimal vibration, and never crashes, with fine workmanship. This pump can handle liquid flows and transport easily flowing mediums, making it a versatile alternative to machinery pumps, submersible pumps, shielding pumps, and mud and trash pumps.

Diaphragm Pump Advantages

» High Suction and Lift Capability: No irrigation water needed, with a suction lift up to 5 meters and a lift up to 70 meters. Outlet pressure can reach ≥ 7 bar.

» Particle Tolerance: Mobile and spacious design, allowing the maximum particle diameter of 10 mm. Ideal for pumping mud and impurities with minimal wear.

» Adjustable Flow and Pressure: Head and flow can be adjusted steplessly through the valve opening degree (pressure adjustment between 1-7 bar).

» No Moving Parts: No shaft seals, with the diaphragm completely separated from the working medium, preventing leaks. Safe for pumping toxic, volatile, or corrosive media without environmental or safety risks.

» Safe for Flammable Environments: No electricity required, making it safe and reliable in flammable and explosive areas.

» Submersible Operation: Can work while immersed in the medium.

» Easy Operation: Simple to use, with reliable performance. Open and close the gas valve to start and stop. The pump can handle long periods of accidental or sudden stops without damage and has self-protective features.

» Simple Structure: Fewer wearing parts, easy to install and maintain. The medium does not come into contact with valves, linkages, or other moving parts.

» Viscosity Handling: Can transport more viscous liquids (viscosity up to 10,000 cps).

» No Lubrication Needed: No lubricating oil required, and idling does not affect the pump.

» Flange Pressure: Plastic flange pressure: PN0.6MPa (10 bar); Metal flange pressure: PN1.0MPa (10 bar).