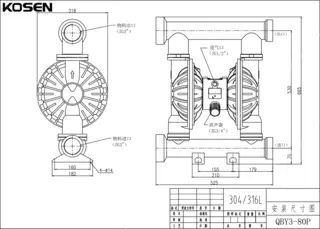

Cast Steel Diaphragm Pump, DN10-DN125, Pneumatic, Threaded

Key Specifications / Features

Detail Information

Product Name: Cast Steel Diaphragm Pump

Port Size: 10-125 mm, DN10-DN125

Pump Material: Aluminum Alloy, Stainless Steel, Carbon Steel, Plastic

Connection: Threaded End

Diaphragm: VITON, PTFE, EPDM, NBR

Ball: PTFE, Stainless Steel, VITON, Ceramic

Seat: PTFE, Stainless Steel, VITON

Maximum Particle Diameter: 6 mm

Operation: Pneumatic Actuator

Temperature: -20 to 150°C

Medium: Various Chemicals: Acids, Alkalis, Solvents, etc

The Pneumatic Diaphragm Pump is the third generation of diaphragm pumps developed by our company, offering reliable quality and long service life. Key features include low noise, minimal vibration, and a robust design that ensures durability. This pump excels in handling a wide range of liquids, including both flowable and challenging mediums. It offers distinct advantages over other transportation machinery pumps, submersible pumps, shielding pumps, and mud and trash pumps. With its fine craftsmanship and performance reliability, the diaphragm pump is an ideal choice for various industrial applications.

Product Advantages

» No need for irrigation water; suction lift up to 5 meters and lift up to 70 meters, with outlet pressure ≥ 7bar.

» High mobility, good performance, and capable of handling particles up to 10 mm in diameter. Suitable for pumping mud and impurities with minimal wear on the pump.

» Stepless head and flow adjustment via valve opening (pressure range: 1-7bar).

» No moving parts and no shaft seals; the diaphragm pump separates the pumping medium from working parts, ensuring that the transmission medium doesn't leak. This makes it ideal for handling toxic, volatile, or corrosive materials without environmental pollution or safety risks.

» Operates without electricity, ensuring safety and reliability in flammable and explosive environments.

» Can be immersed in the medium, making it versatile for various applications.

» Easy to use with reliable operation. Simply open or close the gas valve to start or stop; even after prolonged downtime or sudden shutdowns, the pump will not be damaged. It features automatic shutdown in case of overload, with a self-protective function that resumes operation when the load returns to normal.

» Simple structure with fewer wear parts, making installation and maintenance easy. The pump’s medium does not come into contact with valves, linkages, or other moving parts, unlike other pumps that suffer performance degradation due to rotor, piston, gear, or blade wear.

» Capable of transporting more viscous liquids (up to 10,000 cps).

» No lubricating oil required, and it remains unaffected even when idling, a key feature of this pump.

» Plastic flange pressure: PN0.6MPa (10bar); metal flange pressure: PN1.0MPa (10bar).