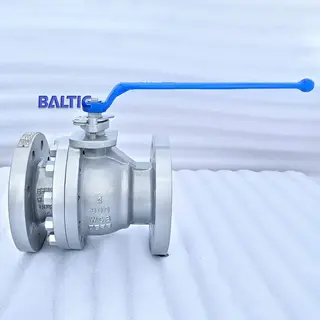

Side Entry Floating Ball Valve, BS 5351, WCB, 4 IN, 300 LB

Key Specifications / Features

Detail Information

Product Name: Side Entry Floating Ball Valve

Design Standard: API 6D, BS 5351

Body Material: ASTM A216 WCB

Size: 4 Inch, DN100

Pressure: Class 300 LB, PN50

End Connection: RF

Operation: Lever

Cast Floating Ball Valve is engineered to provide efficient flow control, using a design where the ball is supported by two PTFE seats: one on the upstream side and one on the downstream side. When pressure from the upstream side pushes the ball, it compresses the downstream seat to create a tight seal, completely shutting off fluid flow. KOSEN’s Cast Floating Ball Valves are known for their high-quality castings and fire-safe design, certified according to BS 6755, API 607, and API 6FA standards. These valves are available in various body types including One-Piece Uni-body, Two-Piece Split Body, and Three-Piece Bolted Body configurations, all designed to meet the latest international standards such as API 6D, ASME B16.34, and BS 5351. With standard features like fire safety, anti-static designs, and blow-out proof stems, these valves provide safe, reliable, and efficient operation for a variety of fluid control applications.

Technical Specifications

» Size Range: NPS 1/2-10 Inch (DN15-DN250)

» Design Pressure: Class 150-600 LB (PN10-PN100)

» Materials: Cast Carbon Steel, Stainless Steel, Duplex, or Other Special Alloys (ASTM A216 WCB, WCC, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M)

» Trim Materials: 13% Cr, SS 304, SS 304L, SS 316, SS 316L, and other specials

» Seat Materials: NYLON, RPTFE, PEEK

» Ends Connections: FF and RF Flange, Welded

» Operation: Handle, Worm Gear, Electric, Pneumatic

» Temperature Range: -46°C to 120°C

» Medium: Water, Gas, Oil, etc.

Standards

» Design and Manufacture: API 6D, BS 5351, ASME B16.34

» Face-to-Face Dimensions: ASME B16.10

» Flanged Connections: ASME B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded End: ASME B16.25

» Fire Safety Standards: API 607, API 6A

Product Features

» Low Operating Torque

» Emergency Sealing Device

» Fireproof Structural Design

» Anti-static Structure

» Reliable Seat Sealing Structure

» Special Structure for Automatic Pressure Relief Toward Upstream

» Blow-out Proof Stem and Stem Flyout Prevention Structure Design

» Corrosion Resistance and Sulfide Stress Resistance

» Optional Locking Device or Stem Extension

» Optional Direct Mounting to ISO 5211

» Full Port or Reduced Bore