Pressure Seal Swing Check Valve, A351 CF8C, 8 Inch, 2500 LB

Key Specifications / Features

Detail Information

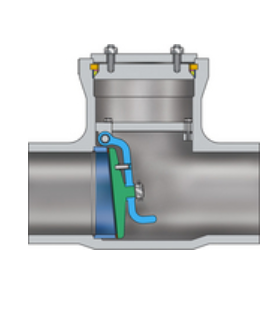

Product Name: Pressure Seal Bonnet Swing Check Valve

Design Standard: BS 1868

Body Material: ASTM A351 CF8C

Size: 8 Inch, DN200

Pressure: Class 2500 LB, PN420

End Connection: BW

Pressure Sealed Check Valves are engineered for high-pressure, high-temperature applications, suitable for a broad range of fluids, excluding those with severe coking tendencies. With their superior design and material selection, these valves offer exceptional service in steam generation stations, industrial chemical plants, and thermal power plants. Available in both Cast Steel and Forged Steel body configurations, the KOSEN Pressure Sealed Check Valves provide excellent reliability and performance across diverse industrial applications.

These valves are designed to ensure efficient flow passage and optimal sealing, contributing to reduced weight, easy installation, and low maintenance costs. Their compact structure and low-emission performance make them ideal for demanding environments.

Technical Specifications

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 600-2500 LB (PN110-PN420)

» Material Options: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: BW, RF, RTJ (meeting international standards)

» Design & Manufacture: BS 1868, API 6D, DIN 3352

» Face-to-Face (End-to-End): ANSI B16.10, EN 558 series

» Flanged Connections: ASME B16.5, ASME B16.47, EN 1092 series

» Butt Welded End: ANSI B16.25

» Test & Inspection: API 598, ISO 5208, EN 12266-1

» Temperature Range: -29°C to 595°C

» Medium Compatibility: Water, gas, oil, etc.

Product Features

» Backflow Prevention: The cast steel swing check valve is designed to prevent reverse flow within the system. As the fluid flows through the valve, the disc swings into the open position, and when there is no flow, back pressure keeps the disc in the closed position. This ensures that flow remains unidirectional and minimizes system disruptions.

» Flexible Installation: These valves can be installed both horizontally and vertically. It is important to align them with the flow direction indicated by the arrow on the valve body for proper operation.

» Customization Options: A variety of accessories such as bypass valves, locking mechanisms, and counterweights can be supplied upon request to meet specific operational requirements.