Pneumatic On-Off Knife Gate Valve, Ductile Iron, GGG40, PN10

Key Specifications / Features

Detail Information

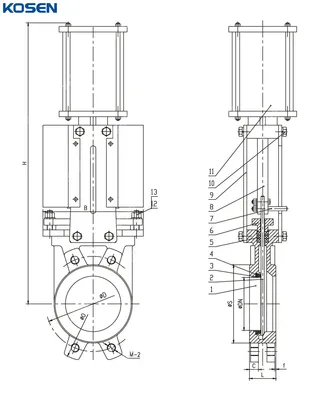

Product Name: Pneumatic On-Off Knife Gate Valve

Type: Unidirectional Knife Gate Valve

Body Material: Ductile Iron GGG40

Size: Customized

Pressure: PN10, Class 150 LB

End Connection: Wafer

Operation: Pneumatic Actuator

The Knife Gate Valve is a unidirectional wafer-style valve designed for on-off operation in industrial pipelines. Its innovative structure prevents clogging during shutoff, ensuring reliable performance when handling media with suspended particles. The beveled knife gate enhances shear force, allowing smooth penetration through flow for efficient operation.

Technical Specifications

» Structure: Unidirectional wafer knife-edge gate valve

» Nominal Diameter: NPS 2–24 Inch (DN50–DN600)

» Design Pressure: PN10, PN16, Class 150 LB

» Temperature Range: -29°C to 538°C

» Max Working Pressure:

DN50–DN250: 10 bar

DN300–DN450: 7 bar

DN500–DN600: 4 bar

» Body Material: Carbon Steel, Stainless Steel, Special Alloys, etc.

» Disc Material: Stainless Steel, Chrome Plated, Special Alloys, etc.

» Seat Material:

Stainless Steel + STL

EPDM (120°C)

Viton (200°C)

PTFE (200°C)

NBR (80°C)

» Flange Standard: GB/T 9113.1, JB/T 79.1, HG 20592, ASME B16.5, EN 1092-1

» Face-to-Face: MSS SP-81

» Applications: Pulp & Paper, Water Treatment, Beverage & Food, Fine Chemicals, Power Plants, Steel Industry, and more

Product Features

» Clog-Free Shutoff & Tight Seal – Cast-in guide claws at the port bottom secure the gate without requiring a groove, preventing clogging while ensuring a reliable seal. These claws push the gate toward the seat for a tight closure.

» Leak-Free & Durable Design – The integral body construction allows for easy assembly and guarantees zero shell leakage.

» Optimized Flow Efficiency – A full-port design minimizes pressure drop and maximizes flow capacity for enhanced performance.

» Enhanced Wear Resistance – PTFE resilient points prevent metal-to-metal contact between the gate and body, reducing friction and extending service life.

» Compact & Easy Installation – The ultra-thin body and compact construction facilitate effortless installation in tight spaces.

» Superior Cutting & Sealing – The beveled knife edge generates high shear stress for effective flow penetration and ensures a tight seal.

» Customizable Pressure Resistance – Gate thickness can be increased to withstand higher pressures when needed.

» Cost-Effective Maintenance – A replaceable side-entry seat design allows for easy seat replacement, reducing maintenance costs.

» Reliable Seat Locking – The L-shape seat retainer securely locks the seat into the valve body and shields it from direct flow exposure, enhancing durability.

» Extended Stem Longevity – A protective stem cover is available to prolong the stem’s service life.

» Smooth Operation – Two thrust bearings minimize operating torque, ensuring effortless valve control.

» Easy Lubrication – A grease nipple is provided for convenient bearing lubrication, enhancing operational efficiency.