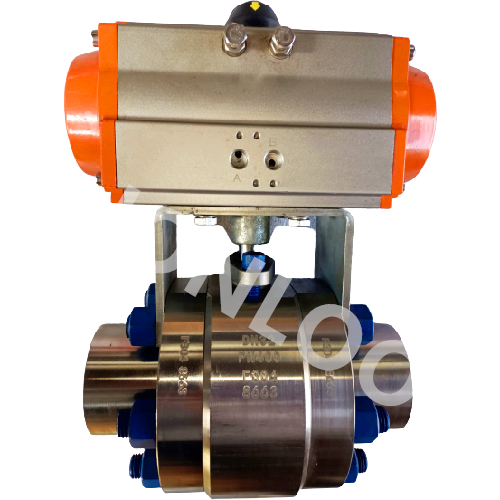

Pneumatic Actuated Ball Valve, A182 F316, 1-1/2 IN, CL800

Key Specifications / Features

Detail Information

Product Name: 3 Piece Floating Ball Valve

Design Standard: ASME B16.34

Body Material: ASTM A182 F316

Size: 1-1/2 Inch, DN40

Pressure: Class 800 LB, PN130

End Connection: FNPT

Operation: Pneumatic Actuator

Forged Steel Ball Valves are available in Two-Piece Split Body and Three-Piece Bolted Body designs. The forged material ensures superior rigidity and strength, even under the maximum rated operating pressure, without the inherent flaws of cast materials. The separate body construction, combined with sufficient wall thickness and high-strength tie bolts, facilitates easy valve maintenance and provides the necessary support to withstand pipe stress. The internal components are carefully designed and selected to ensure reliable performance under a wide range of working conditions.

Technical Specification

» Size Range: 1/2-2 Inch (DN15-DN50) (for Forged Items)

» Design Pressure: Class 150-1500 LB (PN10-PN250)

» Materials:

Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, etc

ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L

» Trim Materials: 13%Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, and other specials

» Seat Materials: PTFE, RPTFE, PEEK

» Ends Connections: SW, FNPT, BW

» Design and Manufacture: ASME B16.34

» Face to Face (End to End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt Welded Ends: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Medium: Water, Gas, Oil, etc.

» Temperature Range: -29°C to 150°C

Product Features

Forged Steel Floating Ball Valves are available in One-Piece Uni-body, Two-Piece Split Body, and Three-Piece Bolted Body configurations. These valves are designed and manufactured to meet the latest international standards, including API 6D, ASME B16.34, BS 5351, or equivalent. Standard features include fire-safe design, anti-static protection, and blow-out prevention, ensuring reliable performance in various applications.