EN 26704 Bimetallic Steam Trap, A216 WCB, DN15, PN16, Flanged

Key Specifications / Features

The EN 26704 Bimetallic Steam Trap is a robust solution for handling steam condensate in industrial plants. Constructed with a carbon steel ASTM A216 WCB body, it features a DN15, 1/2 inch, PN16, and Class 150 LB rating, ensuring durability and reliability. Equipped with flanged ends, this steam trap is designed to efficiently remove condensate while minimizing steam loss, making it an essential component for optimizing steam systems and maintaining operational efficiency.

Detail Information

Product Name: Bimetallic Steam Trap

Design Standard: EN 26704

Body Material: ASTM A216 WCB

Size: DN15, 1/2 Inch

Pressure: PN16, Class 150 LB

End Connection: Flanged

Medium: Steam Condensate

Bimetallic steam traps are designed to conserve energy by discharging sub-cooled condensate in applications where the sensible heat can be effectively utilized. They are the most robust among all types of thermostatic steam traps, capable of withstanding water hammer and corrosive condensate.

Technical Specification

» Product model: CS47 Flange

» Normal Size Range: 1/2-1 Inch (DN15-DN25)

» Normal Pressure Rating: PN16,PN25,Class 150 LB

» Material: ASTM A216 WCB, A351 CF8, CF8M, CF3, CF3M

» Maximum Allowable Pressure (PMA): 40 Bar g

» Maximum Allowable Temperature (TMA): 300°C

» Maximum Differential Pressure (ΔPMX): 32 Bar

» Medium: Steam condensate

» Design and Manufacture: ISO 6552; EN 26704

» Face to face(end to end): EN 26554

» Test and inspection: EN 26948

Application

Bimetallic steam traps conserve energy by discharging sub-cooled condensate in applications that can utilize sensible heat. They are the most robust of all thermostatic steam traps, capable of withstanding water hammer and corrosive condensate.

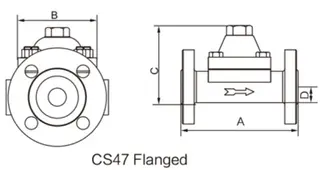

Structural Diagram

Main Dimensions

|

Size |

A |

B |

C |

D |

Weight |

|

DN15 |

150 |

80 |

102 |

20 |

3.7 |

|

DN20 |

150 |

80 |

102 |

20 |

4.3 |

|

DN25 |

160 |

85 |

110 |

23 |

5.3 |