DIN 3352 Wedge Gate Valves, GS-C25, DN200, PN40, RF Flanged

Key Specifications / Features

Our China DIN 3352 Gate Valves are designed for reliable on-off control in various industrial applications. These flexible wedge gate valves feature a carbon steel GS-C25 body, ensuring durability and strength. With a diameter of DN200 (8 inches) and a pressure rating of PN40 (Class 300 LB), they are suitable for high-pressure systems. The raised face (RF) flanged ends provide secure and leak-free connections. Manual operation via a handwheel allows for precise control and ease of use. These valves are ideal for applications requiring robust and reliable gate valve solutions.

Detail Information

Product Name: Flexible Wedge Gate Valve

Type: Wedge Gate Valve

Design Standard: DIN 3352

Body Material: GS-C25

Size: DN200, 8 Inch

Pressure: PN40, Class 300 LB

End Connection: RF Flanged

Operation: Handwheel

Medium: Water, Oil, Gas, etc

Temperature Range: -29°C to 595°C

Wedge Gate Valves are meticulously designed and manufactured to ensure a leakage rate of less than 100 ppm (parts per million) of volatile organic compounds (VOCs). Extensive baseline laboratory testing, including both static and cycle testing, has been conducted to establish the critical design parameters necessary for achieving low-emission sealing in the stem packing seal area and the bonnet gasket sealing area. An in-house testing procedure has been developed and is periodically performed to ensure that our standard product design and manufacturing criteria consistently result in a maximum of 100 ppm VOC leakage prior to shipment.

Technical Specification

» Type: Wedge Gate Valve

» Nominal Diameter: DN50-DN1000

» Design Pressure: PN6-PN40

» Body/Bonnet/Wedge: Cast Steel (EN 1.0619), Stainless Steel (EN 1.4308; EN 1.4408), Alloy Steel EN 1.7335 (WC6)

» Stem: X20Cr13 or EN 1.4021, Stainless Steel (EN 1.4308; EN 1.4408)

» Seat: 13Cr, 18Cr, Stellite

» End Connections: RF Flange, Groove Flange, BW

» Operation: Handwheel, Bevel Gear, Electric, Pneumatic

» Structural Formation: BB-BG-OS & Y

» Design Standard: DIN 3352

» Face-to-Face Dimension: According to EN 558-1 15 (DIN 3202 F5 series)

» Flange Ends: DIN 2543 to 2547, EN 1092-1, GOST 12815, GOST 12819

» Butt Welded End: EN 12627

» Test & Inspection: DIN 3230

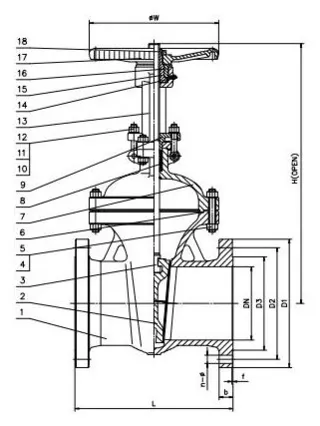

Structural Diagram

Product Features

» Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation.

» Grub screw: Secures the yoke nut in the bonnet.

» Grease nipple: Supplies lubricant to the mating parts.

» OS&Y (Outside Stem and Yoke): Enhances accessibility and maintenance.

» Metal-sealed: Available in Trim #1, #5, #8, #10, and more.

» Optional locking device or stem extension: Provides additional security and versatility.

» Optional direct mounting to ISO 5211: Facilitates compatibility with industry-standard actuators.

» Full port: Ensures maximum flow capacity and reduced pressure drop.