ASTM A352 LCC Wafer Check Valve, API 594, 36 Inch, CL600, RF

Key Specifications / Features

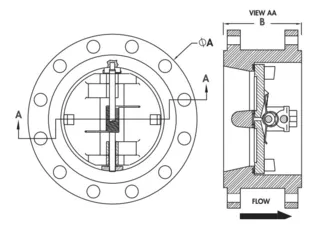

The ASTM A352 LCC Wafer Check Valve is a high-performance valve designed for demanding industrial applications. It features a dual plate design with a low-temperature carbon steel body, conforming to ASTM A352 LCC standards, ensuring durability and reliability in low-temperature environments. The valve adheres to API 594 standards, guaranteeing safety and performance. With a 36-inch (DN900) size and a pressure rating of 600 LB (PN150), it is suitable for high-pressure systems requiring robust flow control. The RF (raised face) flanged ends provide secure and leak-free connections.

Detail Information

Product Name: ASTM A352 LCC Dual Plate Wafer Check Valve

Type: Wafer Check Valve

Design Standard: API 594

Body Material: ASTM A352 LCC

Size: 36 Inch, DN900

Pressure: Class 600 LB, PN150

End Connection: RF Flanged

Temperature Range: -29°C to 595°C

Medium: Water, Gas, Oil, etc.

We specialize in the manufacturing of high-performance wafer check valves, featuring a center vertical pin shaft design. This innovative structure ensures that the fluid force acts on the center of the disc's sealing surface, while the counter spring force acts at the center of the disc body. As a result, the disc opens from the root first, minimizing wear on the sealing surface, a common issue with traditional designs, thereby enhancing the valve’s sealing longevity. The wafer check valve operates automatically, opening and closing based on the medium’s flow, and is specifically designed to prevent reverse flow in pipelines. Its streamlined profile and efficient operation make it suitable for a wide range of industrial applications.

Technical Specification

» Nominal Diameter: NPS 2–60 Inch (DN50–DN1500)

» Design Pressure: Class 150–2500 (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3M, CF8C

» End Connections: wafer, Lug, Flanged.

» Design and Manufacture Standards: API 594, API 6D, JB/T 8937

» Face-to-Face (End-to-End): API 594, API 6D, JB/T 8937, DIN 3202

» Flanged Connection Standards: ANSI B16.5, DIN 2543–48, JB/T 9112–24

» Test and Inspection Standards: API 598, DIN 3230, JB/T 9092

Structural Diagram

Product Features

» Lightweight and compact design

» Soft-seated zero leakage sealing

» Non-slam operation to prevent water hammer

» Bubble-tight shutoff

» 85° disc opening for minimal pressure drop