ASTM A217 WC9 Check Valve, API 6D, 16 IN, 2500 LB, PSB, BW

Key Specifications / Features

Detail Information

Product Name: ASTM A217 WC9 Check Valve, Pressure Seal Bonnet

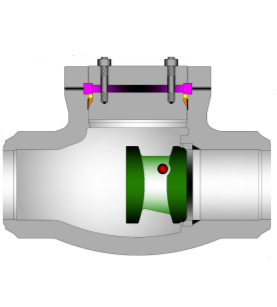

Type: Swing Check Valve

Design Standard: API 6D

Body Material: ASTM A217 WC9

Size: 16 Inch, DN400

Pressure: Class 2500 LB, PN420

End Connection: BW End

Pressure Sealed Check Valves are intended for high pressure, high temperature applications in all types of fluid except where severe coking is a factor. The design and material selections provide excellent service in steam-generation stations, industrial chemical plants, and thermal power plants. Most Pressure Seal valves are offered in Cast Steel and Forged Steel body designs. These options make the Pressure Seal product line an excellent choice for users with various application requirements.

Pressure Sealed Check Valves provide the most efficient flow passage and sealing features possible, resulting in significant weight savings, easy installation, and in-line maintenance. Featured with compact structure & low emission service.

Technical Specifications

» Nominal Diameter: NPS 2-24 Inch (DN50-DN600)

» Design Pressure: Class 600-2500 LB (PN110-PN420)

» Material Options: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C

» End Connections: BW, RF, RTJ (meeting international standards)

» Design & Manufacture: BS 1868, API 6D, DIN 3352

» Face-to-Face (End-to-End): ANSI B16.10, EN 558 series

» Flanged Connections: ASME B16.5, ASME B16.47, EN 1092 series

» Butt Welded End: ANSI B16.25

» Test & Inspection: API 598, ISO 5208, EN 12266-1

» Temperature Range: -29°C to 595°C

» Medium Compatibility: Water, gas, oil, etc.

Product Features

» Cast steel swing check valve is used to prevent backflow in the line. Flow is in a straight line through the valve, resulting in minimal pressure drop. The disc swings into the open position as the media flows through the line, and back pressure in the line holds the disc in the closed position.

» Cast steel swing check valves may be installed in horizontal or vertical lines, but must be installed in proper relation to the media flow as indicated by the flow direction arrow marked on the body.

» Accessories such as bypasses, locking devices, counterweights, and many others are available to meet the customers’ requirements.