ASTM A216 WCB Swing Check Valves, API 6D, 8 Inch, CL300, RF

Key Specifications / Features

Detail Information

Product Name: ASTM A216 WCB Swing Check Valve

Type: Swing Type Check Valve

Design Standard: API 6D

Body Material: ASTM A216 WCB

Size: 8 Inch, DN200

Pressure: Class 300 LB, PN50

End Connection: RF Flanged

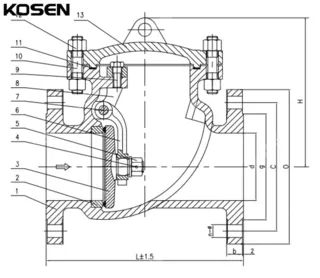

Our Universal Cast Steel Check Valves are engineered to meet international standards such as API 6D, BS1868, and ASME B16.34, offering a design that minimizes flow resistance and pressure drop. These valves are ideal for horizontal pipeline installations, ensuring tight shutoff and long service life through their lapped and screwed-in seat rings. The disc is precisely machined and guided to guarantee efficient automatic shutoff even at zero pressure. Designed with a compact structure, these valves also offer low-emission service. The swing check valve features a bolted cover and a free-swinging clapper that responds to flow conditions, providing effective closure. However, for larger discs that may cause chattering, dampers or counterweights are recommended to prevent issues.

Technical Specifications

» Nominal Diameter: NPS 2–24 Inch (DN50–DN600)

» Design Pressure: Class 150–2500 LB (PN10–PN420)

» Materials: ASTM A216 WCB, WCC, A217 WC6, WC9, C5, C12A, A352 LCB, LCC, A351 CF8, CF8M, CF3, CF3M, CF8C

» End Connections: Flanged (FF, RF, RTJ) to international standards

» Design and Manufacture Standards: BS 1868, API 6D, DIN 3352

» Face-to-Face (End-to-End): ANSI B16.10, EN 558 Series

» Flanged Connections: ASME B16.5, ASME B16.47, EN 1092 Series

» Butt Welded End: ANSI B16.25

» Test and Inspection Standards: API 598, ISO 5208, EN 12266-1

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Features of Swing Check Valve

» Backflow Prevention: The cast steel swing check valve is designed to prevent backflow in pipelines, allowing for smooth flow in a straight line, which minimizes pressure drop.

» Automatic Disc Operation: The valve's disc swings open when media flows through the line, and back pressure keeps the disc in the closed position to prevent reverse flow.

» Flexible Installation: These valves can be installed in both horizontal and vertical lines, as long as the installation follows the proper flow direction indicated by the body's arrow.

» Customizable Accessories: Various accessories such as bypasses, locking devices, counterweights, and others are available to meet specific customer needs and ensure optimal operation.