ASTM A216 WCB Oilfield Ball Valve, 5000 PSI, Full Port, 2 PC

Key Specifications / Features

The ASTM A216 WCB Oilfield Ball Valve Manufacturer offers a robust 2-piece ball valve designed for high-pressure applications. This valve is constructed from ASTM A216 WCB carbon steel, ensuring durability and strength. It features a full port design to maximize flow efficiency and minimize pressure drop. The valve is customizable in size and can handle pressures up to 5000 PSI, making it suitable for demanding oilfield conditions. It is equipped with NPT threaded ends for secure connections and is operated by a lever for easy control.

Detail Information

Product Name: 2PC Oilfield Ball Valve, Full Port

Body Material: ASTM A216 WCB

Size: Custom

Pressure: 5000 PSI

End Connection: NPT

Operation: Lever

Medium: Water, Oil, Gas, etc

Temperature Range: -20°C to 150°C

This ball valve is specifically designed for oil field applications. It consists of a ball valve body and a valve tube. The ball valve body features valve tubes on both the left and right sides. The inner cavity of the ball valve body includes a second slide rail on the right side. The valve rod runs through the entire ball valve body. At the top of the valve rod, a stable block is installed, with a handwheel securely attached to the top of the stable block. Additionally, a limit device is installed within the inner cavity of the valve rod.

Technical Specification

» Type: Oil Field Thread Ball Valve

» Size Ranges: NPS 2-4 Inch (DN50-DN100)

» Temperature Range: -29°C to 120°C

» Pressure: 3000 PSI, 5000 PSI

» Body and Bonnet Material: ASTM A216 WCB

» Seats Material: DELRIN

» Ball and Stem Material: SS 420, SS 304, SS 316

» Ends Connections: ASME B1.20.1 (NPT), API 5B LP

» Inspect and Test: API 598

Product Features

» Threaded Body Construction: Provides a robust and reliable structure.

» Adjustable Packing Gland: Ensures a tight seal and easy maintenance.

» Blow-out-Proof Stem: Enhances safety by preventing the stem from being ejected under pressure.

» Lockable Lever Handle: Allows for secure locking in the open or closed position.

» Lever Operated, Threaded: Easy to operate with a lever handle.

» Floating Ball: Ensures a tight seal and smooth operation.

» Fire Safe Design: Complies with industry standards for fire safety.

» Rugged Locking Device: Provides additional security and reliability.

» Grease Fitting: Facilitates easy maintenance and lubrication.

» NACE MR-0175 Compliant: Suitable for use in sour gas environments.

» Full Port or Reduce Bore Optional: Offers flexibility in flow capacity.

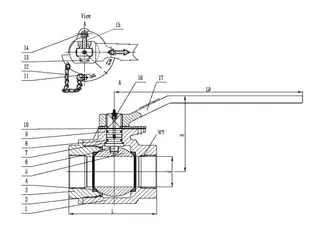

Structural Diagram

Materials of Main Parts

|

No |

Part |

Material |

|

1 |

Body |

ASTM A216 WCB |

|

2 |

Body Seal |

VITON |

|

3 |

Bonnet |

ASTM A216 WCB |

|

4 |

Seats |

DELRIN |

|

5 |

Ball |

SS420, SS304, SS316 |

|

6 |

Stem |

ASTM A276 420 |

|

7 |

Thrust Bearing |

PTFE |

|

8 |

Stem Seal |

VITON |

|

9 |

Stem Seal |

VITON |

|

10 |

Stem Bearing |

PTFE |

|

11 |

Stop Plate |

CS+Ni |

|

12 |

Pin with chain |

Spring Steel |

|

13 |

Retainer Ring |

Spring Steel |

|

14 |

Stop Pin |

Carbon Steel |

|

15 |

Hexagon Bolt |

Carbon Steel |

|

16 |

Grease Zerk |

Ductile Iron |

|

17 |

Handle |

Spring Steel |

Main Dimensions (Inch)

|

Size |

Port |

Pressure |

L |

H |

d |

NPT |

Lo |

Weight (Lbs) |

Torque (in.Lb) |

|

2 Inch |

RP |

3000 PSI |

5.51 |

5.07 |

1.5 |

11.5 |

10 |

12.15 |

1750 |

|

2 Inch |

RP |

5000 PSI |

5.51 |

5.07 |

1.5 |

11.5 |

10 |

14.20 |

2700 |

|

3 Inch |

RP |

3000 PSI |

8.24 |

2 |

2 |

8 |

10 |

23.02 |

2350 |

|

4 Inch |

RP |

3000 PSI |

8.72 |

3 |

3 |

8 |

20 |

42.90 |

3660 |