ASTM A182 F316L Piston Check Valve, API 602, 1/2 IN, 800 LB

Key Specifications / Features

Detail Information

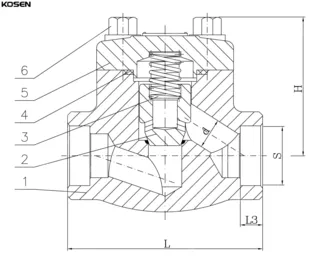

Product Name: Forged Piston Check Valve, Bolted Bonnet

Design Standard: API 602

Body Material: ASTM A182 F316L

Size: 1/2 Inch, DN15

Pressure: Class 800 LB, PN130

End Connection: FNPT

Forged Steel Check Valves are built to meet international standards like API 602 and ASME B16.34. They are designed to minimize flow resistance and pressure drop, ensuring maximum efficiency. These valves are meant for horizontal installation only, with a lapped and screwed seat ring that provides a tight seal for long-lasting service. The valve disc is carefully designed, precisely machined, and guided to ensure automatic shutoff even at zero pressure. Available in both swing and piston styles, these valves have a compact design and low-emission service, offering reliable performance in various applications.

Technical Specifications

» Size Range: 1/2-2 Inch for forged items (DN15-DN50)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Forged Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel(ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L)

» Trim Materials: 13% Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, etc

» End Connections: SW, FNPT, BW, RF, RTJ, Grooved

» Design and Manufacture: ASME B16.34, API 602

» Face-to-Face (End-to-End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt-Welded End: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Product Features

» The lifting check valve helps reduce water hammer during liquid flow, protecting equipment and pipelines from potential impact damage.

» Available with bolted or welded bonnet designs.

» Options include swing-type or lift-type configurations.

» Available in full port or reduced bore designs.