ASTM A182 F304 Piston Check Valve, API 594, DN40, PN16, Wafer

Key Specifications / Features

The ASTM A182 F304 Check Valve is a robust piston check valve with a single disc design, manufactured from forged stainless steel, ensuring high strength and corrosion resistance. It features a DN40 (1-1/2 inch) size, a PN16 pressure rating, and conforms to Class 150 LB standards. The valve is equipped with wafer ends for convenient installation and is ideal for applications requiring reliable backflow prevention and long-term durability.

Detail Information

Product Name: ASTM A182 F304 Piston Check Valve, Single Disc Check Valve

Design Standard: API 594

Body Material: ASTM A182 F304

Size: DN40, 1-1/2 Inch

Pressure: PN16, Class 150 LB

End Connection: Wafer

Medium: Water, Gas, Oil, etc

Temperature Range: -29°C to 595°C

The Single Disc Piston Check Valve is designed to automatically prevent fluid backflow. The valve's disc opens under fluid pressure, allowing fluid to flow from the inlet to the outlet. When the inlet pressure drops below the outlet pressure, the disc closes automatically due to fluid pressure, gravity, and other factors, preventing backflow. This valve can be installed either horizontally or vertically, with vertical installations requiring the fluid to flow from the bottom to the top. Proper installation direction is crucial for effective operation.

Technical Specification

» Type: Single Disc Piston Check Valve

» Nominal Diameter: NPS 1/2-8 Inch (DN15-DN200)

» Design Pressure: Class 150-900 LB (PN10-PN160)

» Material: ASTM A105, A350 LF2, A182 F304, F304L, F316, F316L

» End Connection: Wafer End

» Design and Manufacture: API 594, API 6D, JB/T 8937

» Face to Face (End to End): API 594, API 6D, JB/T 8937, DIN 3202

» Flanged Connection: ANSI B16.5, DIN 2543-48, JB/T 9112~24

» Test and Inspection: API 598, DIN 3230, JB/T 9092

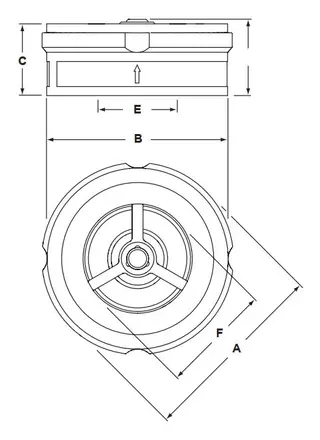

Structural Diagram

Product Features

» Light and Compact: Easy to install and maintain.

» Zero Leakage Sealing Design with Soft Seated: Ensures tight sealing with no leakage.

» Non-Slam Design: Prevents water hammer and reduces noise.

» Bubble Tight Closure: Achieves a perfect seal, even in low-pressure conditions.

» Discs Open 85°: Ensures low pressure drop for efficient fluid flow.