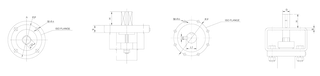

API 609 Butterfly Valves, ASTM A216 WCB, 14 IN, CL300, Lug

Key Specifications / Features

The API 609 Butterfly Valve, manufactured for high-performance applications, features a carbon steel ASTM A216 WCB body for strength and durability. With a 14-inch size (DN350) and a pressure rating of Class 300 LB, PN50, this valve is designed for reliable operation in high-pressure systems. It is equipped with worm gear actuation for precise control and comes with lug ends for easy installation and secure connections.

Detail Information

Product Name: API 609 Butterfly Valves

Type: High Performance Butterfly Valve

Design Standard: API 609

Body Material: ASTM A216 WCB

Size: 14 Inch, DN350

Pressure: Class 300 LB, PN50

End Connection: Lug

Operation: Worm Gear

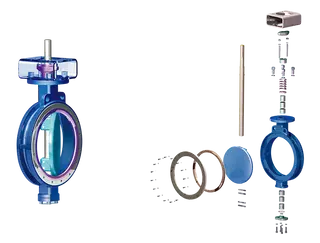

Wafer Type Soft Seat High Performance Butterfly Valves are designed for use in extreme service conditions. These valves are highly effective in a wide range of demanding applications, including high temperature services, throttling steam control, polymerizing media, and liquor service with entrained solids. They are also suitable for high-cycle industrial gas, process gas-off applications, paper stock isolation, vacuum pump isolation, corrosive chemical service, fire-safe refinery and chemical service, heat transfer service, and throttling hydrocarbon service. These valves offer robust performance across various challenging industrial environments.

Technical Specification

» Size Range:

Class 150 LB: 2-60 Inch

Class 300 LB: 2-48 Inch

Class 600 LB: 2-24 Inch

» Pressure Rating:

Class 150-600 LB

PN10-PN40

JIS 10K-20K

» Body Connection: Wafer Type

» Body Materials (Standard): SS 316, ASTM A216 WCB, Alloy 20, Monel, CD3MN, Hastelloy C-276, etc

» Disc Material: ASTM A351 CF8M

» Stem Material: 17-4PH

» Seat Material: SS 316L (or customized material)

» Packing Material: Graphite

» Manual Operator: Worm Gear

» Shutoff Rating: Class V

» Temperature Range: -29°C to 425°C

» Medium: Water, gas, oil, etc.

Application Scope

Wafer Type Soft Seat High Performance Butterfly Valves are widely used across various industries, including:

» Chemical / Petro-Chemical

» Liquefied Gas / Refrigeration

» Heavy Industrial

» Power / Co-Generation Plants

» Steel and Iron Works

» Commercial Applications

» Pulp and Paper Mills

» Oil Refineries and Oil Field

» Ship Building

» Hydrocarbon Processing

» Gas Piping

» Local Area Energy Supply

» Industrial Construction

» Marine Applications

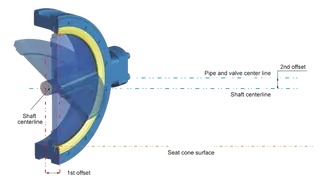

Double Offset Butterfly Valve

The Double Offset High-Performance Butterfly Valve is a new type of butterfly valve designed by absorbing the advantages of several different structural butterfly valves. The sealing surface of the valve plate is a spherical arc surface. The sealing mechanism achieves a true dynamic seal through system pressure, thus providing reliable sealing performance and durability. It features a small volume, light weight, wide manufacturing range, and is easy to maintain and repair. Due to its double offset butterfly plate design and single-piece flexible lip-shaped sealing seat, it is ideal for applications requiring reliable sealing and good regulating characteristics. It can be used for quick shut-off or regulating flow.

Double Offset Frictionless Design

- 1st offset: Shaft is positioned downstream from the centerline of the seat.

- 2nd offset: Shaft is off center from the vertical axis of the seat.

- ISO 5211 Top Flange

- In addition to standard, durable V-ring packing, you can also choose from optional graphite

- high temperature packing or emissions control packing.

- Bi-Directional, Shut off performance

- Seat Options: Rubber, PTFE, RPTFE, or Fire Safe PTFE

- The double offset operating principle minimizes seat wear and lowers operating torque to

- improve durability.

- Positive sealing is mechanically achieved and does not rely on line pressure assistance.

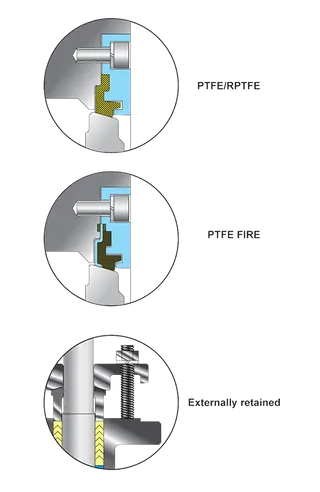

Seat Structure

Double Offset PTFE Seat Butterfly Valve

- A surplus of material between the PTFE Seat and Disc ensures a reliable seal in a low pressure environment.

- In high pressure situations, the force of the medium pushes against the seat contacting the sealing surface for a stronger seal.

- The disc surface has a conical design to reduce frictional force. The valve seat can also be replaced or repaired easily.

Double Offset Fire Safe PTFE Butterfly Valve

- Fire Safe valve seat with dual seal includes a primary PTFE seat insert and metal seat.

- In the event that the PTFE insert is destroyed, the secondary metal seat provides an effective shut-off.

Shaft Retention

- Externally retained, double blowout proof stem design as API 609

- External: Shaft is designed with an integral collar and gland follower to prevent blowouts.

Zero Leakage

- Disc-Seat sealing is achieved by evenly loading torque force onto the disc's laminated seal

ISO 5211 Top Mounting

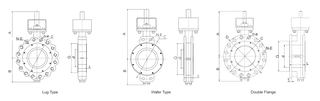

Different End Connections Available: