API 602 Globe Valve, ASTM A105N, 3/4 Inch, CL1500, BB, FNPT

Key Specifications / Features

Detail Information

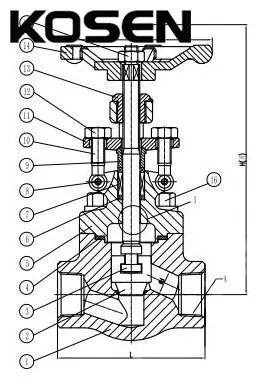

Product Name: API 602 Forged Globe Valve

Features: Bolted Bonnet, Reduce Bore

Design Standard: API 602

Body Material: ASTM A105N

Size: 3/4 Inch, DN20

Pressure: Class 1500 LB, PN250

End Connection: FNPT

Operation: Manual

Forged Steel Globe Valves are engineered and manufactured in full compliance with international standards such as API 602, ASME B16.34, and DIN 3202, or their equivalents. These valves feature a compact yet robust design, making them suitable for high-pressure and high-temperature applications. The optional solid CoCr alloy wedge ensures minimal friction and extended service life. The packing rings are pre-compressed to 4000 psi, providing a high-integrity seal. For welded bonnet valves, the bonnet is threaded and torqued to an engineered value, while the body-bonnet joint is strength-welded, offering double protection against leakage. This dual protection (body, bonnet threads, and strength-weld) ensures a secure, leak-free operation. The fully guided wedge reduces wear on seating surfaces, enhancing valve longevity. Additionally, optional features include double packing, leak-off connections, live-loading, and a packing blowout for easy packing removal.

Technical Specifications

» Size Range: NPS 1/2-2 Inch (DN15-DN50)

» Design Pressure: Class 150-2500 LB (PN10-PN420)

» Materials: Carbon Steel, Alloy Steel, Stainless Steel, Duplex Steel, and other materials such as ASTM A105N, A350 LF2, A182 F11, F22, F304, F304L, F316, F316L

» Trim Materials: 13% Cr, ASTM A182 F11, F22, SS 304, SS 304L, SS 316, SS 316L, etc.

» End Connections: SW, FNPT, BW, RF, RTJ, Grooved

» Design and Manufacture: ASME B16.34, API 602

» Face-to-Face (End-to-End): ANSI B16.10

» Flanged Connection: ANSI B16.5

» Test and Inspection: API 598, API 6D

» Butt-Welded End: ANSI B16.5

» Threaded Ends: ASME B1.20.1

» Socket-Weld Ends: ASME B16.11

» Temperature Range: -29°C to 595°C

» Medium: Water, gas, oil, etc.

Product Features

» Corrosion Resistance: After fine processing, forged steel materials offer excellent corrosion resistance, making them suitable for various corrosive media and extending the valve's service life.

» Reduced Bore Design: Features a reduced bore design for high flow and minimal pressure drop, with an optional full-bore configuration available for specific applications.

» Bolted Bonnet: Constructed from high-quality forged material, the bolted bonnet ensures metal-to-metal surface contact for automatic gasket compression control, preventing joint over-stressing.

» Graphite Packing: Equipped with graphite packing rings that include a built-in corrosion inhibitor, providing leak-tight sealing performance across high and low pressures and temperatures.