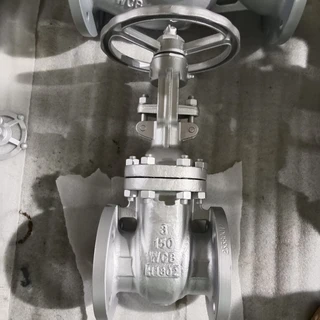

Rising Stem Gate Valve, API 600, WCB, 14 IN, CL300, OS&Y, RF

Key Specifications / Features

Detail Information

Product Description: Flexible ASTM A216 WCB gate valve, carbon steel, bolted bonnet, rising stem, OS&Y, wedge gate, renewable seat, back seat, full bore.

Design Standard: API 600

Body Material: ASTM A216 WCB

Nominal Diameter: 14 Inch, DN350

Nominal Class: Class 300 LB, PN50

Face to Face: ASME B16.10

Test and Inspection: API 598

Wedge Material: ASTM A216 WCB+STL

Seat Material: ASTM A105+STL

Mode of Operation: Gearbox

End Connection: RF Flanged (Raised Face)

API 600 gate valves typically feature a wedge-type gate, which can be either a solid or flexible wedge design. In the open position, the gate should fully retract from the valve seat hole, except in the case of parallel double-disc gates.

We also produce the following gate valves:

API 600 OS&Y Gate Valve,

API 600 Wedge Gate Valve, OS&Y

Size Range and Pressure Class

Size Range: 2 Inch to 40 Inch (DN50 to DN1000)

Pressure Class: Class 150 LB to 1500 LB (PN16 to PN240)

Design Standards

Design / Manufacture: API 600

Face to Face Length (Dimension): ASME B16.10

Flanged Dimension: ASME B16.5

Flanged Ends:

ASME B16.5: For sizes 2 Inch to 24 Inch

ASME B16.47 Series A / B: For sizes 26 Inch and above

Clamp or hub ends available upon request.

Butt Welding Ends: ASME B16.25

Testing: API 598

Technical Features

Wedge Gate, OS&Y Design: Features a wedge-type gate with an outside screw and yoke design.

Compliance: Designed and manufactured in accordance with API standards.

Surface Material: Stellite cobalt-based hard alloy for high-pressure valves, offering exceptional durability.

Sealing Face: Wear-resistant, corrosion-resistant, and scratch-resistant for reliable performance.

Service Life: Long-lasting with a robust design for extended use.

Valve Stem: Corrosion-resistant and scratch-resistant for improved longevity.

Gate Structure: Wedge-type elastic gate for effective sealing.

Bearings: Rolling bearings facilitate smooth and easy opening and closing.

Versatility: Suitable for a wide range of pressure, temperature, and medium conditions.

CONSTRUCTION MATERIALS

General Cast Carbon Steel: ASTM A216 WCB, WCC, WCA, GP240GH (1.0619 / GS-C25)

Low Temperature Carbon Steel (LTCS): ASTM A352 LCB, LCC, LCA, GS-CK25

Alloy Steel:

ASTM A352 LC1, LC2, LC2-1, LC3, LC4, LC9, ASTM A743 CA6NM,

GS-CK16, GS-CK24, GS-10Ni6, GS-10Ni14

High Temperature Steel (Chrome Moly)/Alloy Steel:

ASTM A217 WC1, WC6, WC9, C5, C12, C12A

GS-22Mo4/ G20Mo5 (1.5419), GS-17 CrMo5-5/ G17 CrMo5-5 (1.7357)

Austenitic Stainless Steel/Alloy Steel:

UNS S30400 (S30403) (S30409), ASTM A351 CF8, CF3, CF10

G-X6CrNi189/ GX5CrNi19-10 (1.4308)

UNS S31600 (S31603) (S31609), ASTM A351 CF8M, CF3M, CF10M

GX5CrNiMo19-11-2/G-X6CrNiMo18.10 (1.4408)

UNS S34700 (S34709), ASTM A351 CF8C

G-X5CrNiNb189/GX5CrNiNb19-11 (1.4552)

AISI 316Ti, X6CrNiNo17122/ X6CrNiMoTi17-12-2 (1.4571)

Alloy 20 / UNS N08020, ASTM A351 CN7M

Ferritic-Austenitic / Duplex / Super Duplex Stainless Steel:

UNS S31803 /S32205 (Duplex 2205), ASTM A890/A995 Grade 4A (J92205)/ ASTM A351 CD3MN

UNS S32750 (Super Duplex 2507), ASTM A890/A995 Grade 5A / ASTM A351 CE8MN (CD4MCu)

UNS S32760, ASTM A890/A995 Grade 6A (CD3MWCuN)

Other Materials:

Alloy 20, ASTM B462 UNS N08020

Monel 400 / UNS N04400 / ASTM B564-N04400) / ASTM A494 M35-1, NiCu30Fe (2.4360)

Nickel Alloy 904L / UNS N08904, X1NiCrMoCu25.20.5 (1.4539)

Inconel 625 / UNS N06625 / ASTM B564-N06625 / ASTM A494-CW6MC, NiCr22Mo9Nb (2.4856)

Inconel 825 / UNS N08825 / ASTM B564-N08825 / ASTM A494 CU5MCuC (2.4858), NiCr21Mo (2.4858)

Send your message to this supplier

FAQs

What is a Non-Rising Stem Gate Valve?

A valve where the stem does not move vertically but rotates internally to raise or lower the gate. This design is ideal for installations with limited vertical space.

How Does a Non-Rising Stem Gate Valve Work?

The handwheel turns the stem, which in turn moves the gate up or down inside the valve body without changing the external height of the stem.

How Does a Rising Stem Gate Valve Work?

The handwheel lifts the stem and gate together, providing a visual indication of whether the valve is open or closed.

Which Valve Should I Choose?

Use a rising stem valve for above-ground applications where visibility and ease of maintenance are important.

Use a non-rising stem valve for underground or space-limited installations.

Conclusion

The choice between rising stem and non-rising stem gate valves depends on your specific application needs. For clear valve status indication and easy maintenance, go with a rising stem valve. For compact installations, a non-rising stem valve is the better option.