Pressure Balanced Lubricated Plug Valve, API 599, 1/2-24 Inch

Key Specifications / Features

Introducing our Pressure Balanced Lubricated Plug Valve, expertly crafted by a leading manufacturer in China. Available in sizes ranging from 1/2 to 24 inches, with class ratings of 150-900 LB, this valve meets API 599 and DIN 3202 standards. Manufactured from high-quality alloy and stainless steel, it features a full bore design, ensuring efficient and reliable performance. Trust in our commitment to excellence for your pressure-balanced lubricated plug valve requirements.

Request a quote

Detail Information

Lubricated Pressure Balanced Plug Valve Feature

1. The valve features a well-thought-out design, ensuring a reliable seal, exceptional performance, and an aesthetically pleasing appearance.

2. It incorporates a flip-chip balanceable pressure structure, offering smooth and effortless on/off operation.

3. A sealant groove between the valve body and sealing surface allows for the infusion of seal grease, enhancing sealing capability.

4. Materials and flange dimensions can be customized based on operational conditions and user requirements, catering to diverse engineering needs.

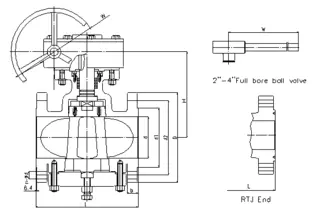

Lubricated Pressure Balanced Plug Valve Feature Structure

Lubricated Pressure Balanced Plug Valve Class 150 LB Dimension

| NPS | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 | 337 | 387 | 438 | 489 | 591 |

| L(RF) | mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1016 |

| d1 | mm | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 120.5 | 139.5 | 152.5 | 190.5 | 241.5 | 298.5 | 362 | 432 | 476 | 540 | 578 | 635 | 749.5 |

| D | mm | 152 | 178 | 190 | 229 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 |

| b | mm | 16 | 18 | 19 | 24 | 26 | 29 | 31 | 32 | 35 | 37 | 40 | 43 | 48 |

| n-Фd | mm | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 12-25 | 12-25 | 12-29 | 16-29 | 16-32 | 20-32 | 20-35 |

| H | mm | 175 | 180 | 190 | 214 | 270 | 370 | 420 | 490 | 500 | 645 | 690 | 740 | 800 |

| W | mm | 350 | 600 | 700 | 700 | 900 | 600 | 600 | 600 | 600 | 700 | 760 | 760 | 760 |

Lubricated Pressure Balanced Plug Valve Class 300 LB Dimension

| NPS | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 | 337 | 387 | 432 | 483 | 584 |

| L(RF) | mm | 216 | 241 | 283 | 305 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 |

| d1 | mm | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 149 | 168.5 | 200 | 270 | 330 | 387.5 | 451 | 514.5 | 571.5 | 628.5 | 686 | 813 |

| D | mm | 165 | 190 | 210 | 254 | 318 | 381 | 445 | 521 | 584 | 648 | 711 | 775 | 914 |

| b | mm | 23 | 26 | 29 | 32 | 37 | 42 | 48 | 51 | 54 | 58 | 61 | 64 | 70 |

| n-Фd | mm | 8-19 | 8-22 | 8-22 | 8-22 | 12-22 | 12-25 | 16-29 | 16-32 | 20-32 | 20-35 | 24-35 | 24-35 | 24-41 |

| H | mm | 184 | 190 | 195 | 265 | 307 | 390 | 433 | 500 | 630 | 740 | 790 | 830 | 890 |

| W | mm | 500 | 550 | 600 | 700 | 900 | 600 | 600 | 700 | 700 | 760 | 760 | 760 | 760 |

Lubricated Pressure Balanced Plug Valve Class 600 LB Dimension

| NPS | in | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 76 | 102 | 127 | 152 | 200 | 248 | 298 | 327 | 375 | 419 | 464 | 559 |

| L(RF) | mm | 292 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 |

| L(RTJ) | mm | 295 | 359 | 435 | 511 | 562 | 664 | 791 | 841 | 892 | 994 | 1095 | 1200 | 1407 |

| d1 | mm | 92 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 168.5 | 216 | 267 | 292 | 349 | 432 | 489 | 527 | 603 | 654 | 724 | 838 |

| D | mm | 165 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | 603 | 686 | 743 | 813 | 940 |

| b | mm | 26 | 32 | 38 | 45 | 48 | 56 | 64 | 67 | 70 | 77 | 83 | 89 | 102 |

| n-Фd | mm | 8-19 | 8-22 | 8-25 | 8-29 | 12-29 | 12-32 | 16-35 | 20-35 | 20-38 | 20-41 | 20-44 | 24-44 | 24-52 |

| H | mm | 194 | 205 | 270 | 300 | 350 | 405 | 460 | 500 | 630 | 740 | 790 | 830 | 890 |

| W | mm | 500 | 780 | 1100 | 600 | 600 | 600 | 600 | 700 | 700 | 760 | 760 | 760 | 760 |

API 6D Flange Pressure Lubricated Plug Valve-Specifications and Materials

Design and manufacture: API 599, ASME B16.34, DIN 3202

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded Ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Body material: ASTM A216 WCB, ASTM A352 LCB, Alloy Steel ASTM A217 WC6, WC9, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, Duplex ASTM A890 4A, 5A, Special Alloy, Monel, Bronze C95800, Alloy 20

Trim material: ASTM A216 WCB, ASTM A352 LCB, ASTM A105, Alloy Steel ASTM A217 WC6, WC9, ASTM A182 F11, Stainless Steel ASTM A351 CF8, CF8M, CF3, CF3M, ASTM A182 F304, F316, F304L, F316L, Duplex ASTM A890 4A, 5A, ASTM A182 F51, F55, Special Alloy, Monel, Bronze C95800, Alloy 20

Size range: 1/2 Inch - 24 Inch, DN15 - DN600

Pressure range: Class 150 - 900 LB

Drive Mode: Manual, Worm gear, Electric, Pneumatic

Field of Application: Electric/Hydraulic/Municipal Engineering etc; Water/Sea water/Gas etc.

-320x321.webp)