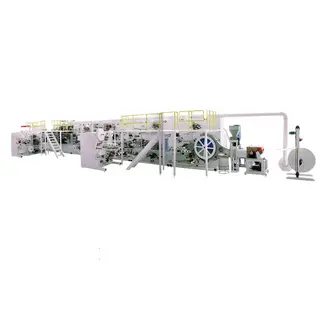

Low Cost Full Auto Adult Diaper Machine with Touch Screen

Key Specifications / Features

Detail Information

Low Cost Full Auto Adult Diaper Machine with Touch Screen

| Subject | Parameter |

| Overall size(L*W*H) | 24M*4M*3.6M(For reference only) |

| Machine size(L*W*H) | 22m*2.1m*3.3m,based on the product provided by client |

| Design speed | 300pcs/min |

| Stable speed | 180pcs/min |

| Pass precentage | 98% |

| Work efficiency | 85%-90% |

| Power source | 380V,50HZ,(3phase,4lines+ground wire) |

| Machine capacity | about 400KW |

| Air pressure | 0.6-0.8Mpa |

| Machine weight | About 95T |

| Machine color | Customized |

Configuration:

1. Frequecy motor/servo motor driving controlled by PLC with touch screen;

2. Raw materials auto unwinding with tension control and auto spliciing units;

3. Raw Materials web guiding units;

4. Single high speed cell mill;

5. Single drum former for continuous fluff core formation;

6. Single SAP applicator;

7. Laminatited core (fiber cotton with SAP) unwinding and feeding units (option);

8. Fluff core embossing and cutting units;

9. 3D floating core applicator (option);

10. ADL/Air-laid paper feeding & cutting units;

11. Elastic band unwinding and feeding unit;

12. 3D side leakage guard applicating unit;

13. Leg cuff applicating unit;

14. Elastic waistband cutting and applicating unit;

15. Backsheet lamination unit;

16. Side tapes cutting and applicating unit;

17. Frontal tape positioning and cutting unit;

18. Rotary die cutting unit;

19. Final cutting unit;

20. Stacker (option);

21. Packing machine (option);

22. Dust collection filter system (option)

Main Product:

1. Baby diaper Production Line

2. Adult diaper Production Line

3. Sanitary Napkin & Panty Liner Production Line

4. Menstruation Panty Production Line

5. Under Pad Production Line

6. Disposable Breast Pad Production Line

Send your message to this supplier

FAQs

Basic Concept

Low Emission Valves refer to valves that, through special design and manufacturing processes of the stem packing and mid-seat gasket, control the leakage of media (gases, liquids) to extremely low levels. They are primarily used in industrial scenarios with high safety and environmental protection requirements. The core objective is to reduce or prevent the leakage of harmful media (such as volatile organic compounds (VOCs), toxic gases, flammable and explosive substances, etc.) into the external environment. Therefore, low emission valves offer multiple advantages in terms of energy conservation, emission reduction, reduced safety risks, and environmental pollution.

Key Technical Standards and Leakage Grades

The performance of Low Emission Valves is quantified by their leakage rate, and different industries follow different standards. Common standards include:

1. International Standards

ISO 15848-1: This standard classifies valve leakage grades into four levels: A (the highest requirement), B, C, and D. Grade A requires a leakage rate of ≤100 ppm (by volume).

API 624 (American Petroleum Institute): This standard, applicable to the refining and chemical industries, specifies a leakage rate of ≤100 ppm (for gases) under specific pressures.

EPA Standard (U.S. Environmental Protection Agency): This standard, targeting VOC emissions, requires a leakage rate of ≤500 ppm.

2. Chinese Standards

GB/T 42223-2022: This standard, which references international standards, regulates the design, manufacturing, and testing of Low Emission Valves.

|

Comparison Dimension |

Traditional Valves |

Low Emission Valves |

|

Leakage Rate |

Typically ≥1000 ppm (for gases) |

≤100 ppm (some can reach ≤10 ppm) |

|

Sealing Structure |

Single seal (e.g., packing gland) with poor initial stability, susceptible to temperature changes and impact |

Single seal (e.g., packing gland) with long-term extreme stability, unaffected by temperature changes and impact |

|

Testing Requirements |

Hydrostatic / Pneumatic tests |

Helium leak detection (leakage rate ≤1×10⁻⁷ Pa・m³/s) |

|

Cost |

Lower |

Slightly higher, but less than 1-2% more than traditional valves |

|

Applicable Media |

General industrial fluids |

High-risk, high-value, and high environmental protection requirement media |

Storage Performance Deficiencies of Traditional Valves

Traditional valves using ordinary graphite packing face dual storage risks.

1. Physical Adsorption Leading to Operational Failure

During long-term static storage, graphite molecules adhere to the valve stem surface due to van der Waals forces, forming a rigid adsorption layer. This increases the valve opening torque by 2-3 times compared to the initial value. In extreme cases, it may cause the actuator to overload and fail.

2. Chemical Corrosion Leading to Seal Degradation

Ordinary graphite packing typically has a sulfur content of ≥1200 ppm (by mass). In storage environments with humidity ≥60%, sulfur reacts with the metal valve stem through electrochemical corrosion, forming a FeS corrosion layer. This enlarges the seal interface gap, causing the leakage rate to increase exponentially over time, with an average annual leakage increase of 30%-50%.

Storage Performance Advantages of Low Emission Valves

Low Emission Valves achieve a breakthrough in storage stability through the following means:

1. Upgraded Material System

Sealing Packing: High-purity sulfur-free graphite (sulfur content ≤0.01%) with ≥99.5% purity is used. The interlayer bonding is enhanced through nano-scale flake orientation technology, blocking the migration path of sulfur elements.

Mid-flange Gasket: Modified flexible graphite composite material with 15%-20% nickel-based alloy reinforcement is used to form a corrosion-resistant skeletal structure.

2. Performance Verification Data

Traditional Valves: Opening torque increases from 80 N•m to 220 N•m, and leakage rate rises from 500 ppm to 2800 ppm.

Low Emission Valves: Opening torque fluctuation is ≤±5%, and leakage rate remains below 20 ppm, fully meeting the stringent long-term storage performance requirements of API 624.

At first, manufacturing low emission valves was pretty much the same for us as it was for other regular valve manufacturers in China. If we ran into problems like valves not passing tests or having leak rates that kept changing, we'd just try to get better packing materials from a different supplier. We didn't really stop to think about the bigger picture, like how the whole manufacturing process or the properties of the materials we were using might be causing the issues.

Over time, we figured out that the metal parts of the valves were pretty reliable, but we hadn't been paying enough attention to the non-metal parts that actually do the sealing. And those parts are super important for making sure the valves don't leak. So, back in 2008, we decided to focus on manufacturing low emission valves from start to finish.

First, we created a special team just for figuring out better ways to seal valves. They dug deep into how to make the seals work really well and how to build them. At the same time, we started working closely between the people who design the seals and the people who manufacture the valves. By tweaking the design of the seals and how we put the valves together, we made a system where everything works together perfectly. After that, we tested a bunch of different valves to see how well they sealed in all kinds of situations: different sizes, pressures, and temperatures. All the data we collected from these tests helped us keep improving our valves.

Now, when we manufacture a bunch of valves and check them randomly, they all meet the tough standards of API 624 and ISO 15848-1. We've gone from just following a process to really understanding and controlling the technology ourselves.