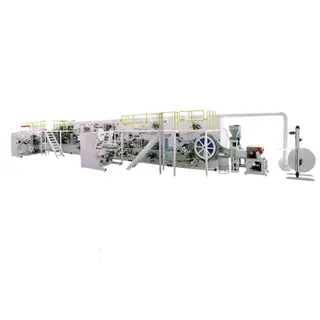

BST Automatic Web Guide I Shape Baby Diaper Making Machines

Key Specifications / Features

Explore our BST Automatic Web Guide I Shape Baby Diaper Making Machines, designed for peak efficiency. These machines are engineered with a dependable 3-shaft mechanical drive, ensuring a production rate of 500 pieces per minute.

Request a quote

Detail Information

BST Automatic Web Guide I Shape Baby Diaper Making Machines

| Subject | Parameter |

| Overall size(L*W*H) | 24M*4M*3.6M(For reference only) |

| Machine size(L*W*H) | 22m*2.1m*3.3m,based on the product provided by client |

| Design speed | 500pcs/min |

| Stable speed | 400pcs/min |

| Pass percentage | 98% |

| Work efficiency | 85%-90% |

| Power source | 380V,50HZ,(3phase,4lines+ground wire) |

| Machine capacity | about 280KW |

| Air pressure | 0.6-0.8Mpa |

| Machine weight | About 55T |

| Machine color | Customized |

Configuration:

Product Components:

Fluff Core with Up & Down Tissue (incorporating SAP), ADL Layer, Backsheet, Frontal Tape, Topsheet, Leg Cuff Nonwoven, Side Tapes, Waistband.

Product Sizes:

Small (S): 390 x 280 mm

Medium (M): 450 x 320 mm

Large (L): 500 x 320 mm

Extra Large (XL): 525 x 330 mm

Control System:

PLC control with a touchscreen interface

LED digital display for pattern-based production control

Tension System:

A&B shaft active unwinding powered by inverter motors for Tissue, ADL, Backsheet, Topsheet, and Cuff Nonwoven.

Drive System:

3-shaft mechanical drive,semi servo,full servo can be choose by customer's requirements

Safety Features:

Safety devices and an emergency stop switch on the operating side

High-performance fan with sound insulation or a silencer

Packing Options:

Stacker available upon client's request

Material Alignment System:

Optional German BST automatic web guide system for precise material alignment.

Main Product Lines:

- Baby Diaper Production Line (Includes I & T shape diaper, Baby pants, Full Elastic waistband diaper)

- Adult Diaper Production Line (Includes Adult diaper, Adult pants)

- Sanitary Napkin & Panty Liner Production Line

- Menstruation Panty Production Line

- Under Pad Production Line

- Disposable Breast Pad Production Line