Electric On/Off Control Valve, Stainless Steel CF8M, 1/4-6 IN

Key Specifications / Features

Introducing our motor-operated control valve, which seamlessly integrates a state-of-the-art electric linear actuator with our innovative sliding gate valve seat design. This combination delivers unparalleled accuracy, making it the perfect final control element for distributed process control systems. Engineered for precision and reliability, this valve ensures optimal performance in demanding industrial applications. Its advanced design allows for precise control and efficient operation, contributing to improved system accuracy and stability. Ideal for various industrial settings, this motor-operated control valve is a robust and reliable solution for your process control needs.

Request a quote

Detail Information

SPECIFICATIONS

Product Name: Electric Motor Operated Control Valve

Key Features: On/Off, Motorized Control, Electronic

Size Range: 1/4 Inch - 6 Inch, DN8-DN150

Body Material: Carbon Steel, Stainless Steel, Ductile Iron, Cast Iron, Bronze

Trim Materials:

SS 303 for DI, BZ or CS Valves

SS 316 for SS Body Valves

Yoke Material: Cast Iron

Seat Materials: SS304 T/Jorcote, SS 316 T/Jorcote

Stem Packing: Spring-loaded Teflon (500°F max/260°C)

Braided (above 500°F/260°C)*

*CML 250 required 1/2 Inch - 2 Inch

*CML 750 required 2 1/2 Inch - 6 Inch

Service: steam, water, air, oil, gas and chemicals

Shutoff: ANSI Class IV

Flow Characteristic: Linear, Equal Percentage

Cv (Kv): Up to 395 (up to 340)

Seat Material: Jorcote

Command Signals: Current or Voltage Command, On/off

End Connections:

Threaded (NPT, BSPT, BSPP – through 2 Inch sizes)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Temperature Limits:

CML 100/250/750: -4°F to +150°F (-20°C to +66°C)

Optional low temperature trim for CML motors: -40°F to +150°F (-40°C to +66°C) CF

Features & Benefits:

1. Shorter Stroke: Faster operation compared to globe or plug-style valves.

2. Enhanced Durability: Long packing and stem life, with stem packing four times deeper than stem travel.

3. Straight-Through Flow: Sliding gate seats reduce turbulence and ensure quiet operation.

4. Quick Response: Short stroke enables faster response and precise regulation.

5. Interchangeable Cv Values: Easy to switch for different flow requirements.

6. Tight Shutoff: Ensures reliable sealing and performance.

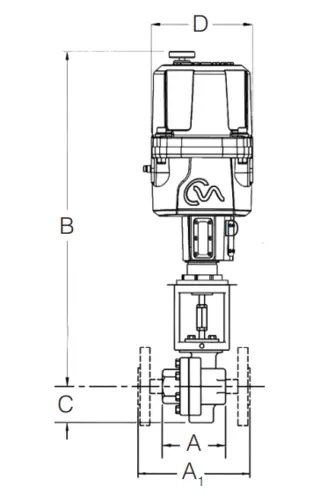

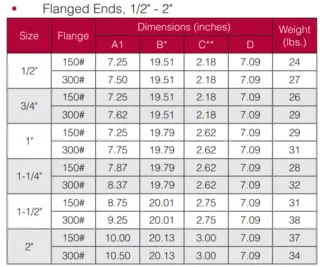

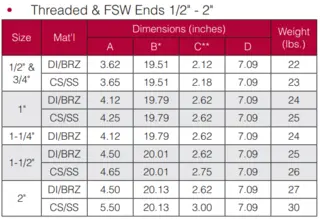

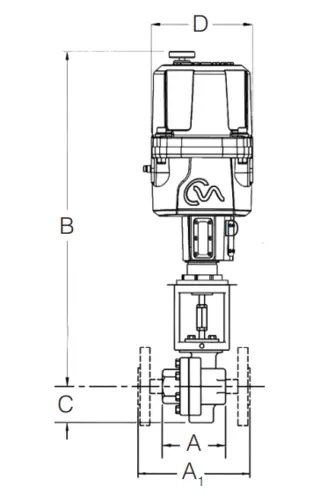

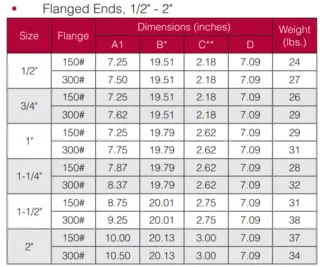

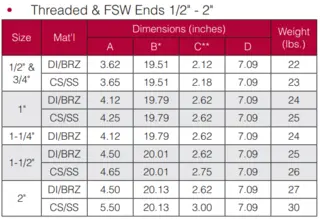

Dimensions:

Product Name: Electric Motor Operated Control Valve

Key Features: On/Off, Motorized Control, Electronic

Size Range: 1/4 Inch - 6 Inch, DN8-DN150

Body Material: Carbon Steel, Stainless Steel, Ductile Iron, Cast Iron, Bronze

Trim Materials:

SS 303 for DI, BZ or CS Valves

SS 316 for SS Body Valves

Yoke Material: Cast Iron

Seat Materials: SS304 T/Jorcote, SS 316 T/Jorcote

Stem Packing: Spring-loaded Teflon (500°F max/260°C)

Braided (above 500°F/260°C)*

*CML 250 required 1/2 Inch - 2 Inch

*CML 750 required 2 1/2 Inch - 6 Inch

Service: steam, water, air, oil, gas and chemicals

Shutoff: ANSI Class IV

Flow Characteristic: Linear, Equal Percentage

Cv (Kv): Up to 395 (up to 340)

Seat Material: Jorcote

Command Signals: Current or Voltage Command, On/off

End Connections:

Threaded (NPT, BSPT, BSPP – through 2 Inch sizes)

ANSI Flanges (150#, 300#)

DIN Flanges (PN10/16, PN25/40)

Temperature Limits:

CML 100/250/750: -4°F to +150°F (-20°C to +66°C)

Optional low temperature trim for CML motors: -40°F to +150°F (-40°C to +66°C) CF

Features & Benefits:

1. Shorter Stroke: Faster operation compared to globe or plug-style valves.

2. Enhanced Durability: Long packing and stem life, with stem packing four times deeper than stem travel.

3. Straight-Through Flow: Sliding gate seats reduce turbulence and ensure quiet operation.

4. Quick Response: Short stroke enables faster response and precise regulation.

5. Interchangeable Cv Values: Easy to switch for different flow requirements.

6. Tight Shutoff: Ensures reliable sealing and performance.

Dimensions: