8 Inch Dual Plate Check Valve, Al-bronze, B148 C95800, CL300

Key Specifications / Features

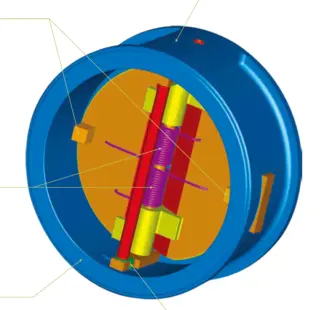

We are a reliable supplier of dual plate non-return check valves built to API 594 specifications. This 8-inch valve features a durable aluminum bronze body made from ASTM B148 C95800, offering excellent corrosion resistance for harsh environments. Designed for Class 300 LB pressure ratings, it is equipped with flanged ends for secure and straightforward installation. The valve is available with NBR, Viton, or EPDM seats to suit a variety of fluid applications. Ideal for marine, chemical, and industrial systems where backflow prevention is critical.

Detail Information

Valve Description:

187303027 Dual Plate Check Valve

Design Standard: API 594

Structure: Spring-loaded, Dual Plate

Nominal Size: 8 Inch, DN200

Nominal Class: 300 LB

Bore Type: NA

End Connection: Wafer/LUG/Double Flanged

Operation: NA

Body Material: ASTM B148 C95800

Trim Material: ASTM B148 C95800

Face to Face: API 594

Test and Inspection: API 598

Key Features:

Compact, space-saving design.

Independent spring mechanism for reliable closing.

Optional soft or metal seat to suit various applications.

Unique slim disc design for reduced pressure drop.

Aluminum bronze construction is ideal for seawater and corrosive environments.

Product Range:

Body Material: Aluminium Bronze

Normal Diameter: 1/2 Inch - 48 Inch (DN15 - DN1200)

Pressure Range: Class 150 LB - Class 300 LB

End Connection: Wafer, Lug, RF Flanged, RTJ

Working Temperature: -229°C - +1120°C

Operation: Not Applicable (Manual or actuated available for special request)

The Dual Plate Check Valve is a spring-loaded non-return valve designed to allow fluid flow in one direction and prevent backflow in pipelines. It features a one-piece body, a centrally positioned pin, and two spring-loaded plates mounted on the pin. When fluid flows in the intended direction, the plates open to allow passage; when the flow reverses, the springs quickly close the plates to block backflow.

Compared to conventional swing check valves, the dual plate design offers significant advantages by reducing both weight and length. This compact construction helps lower material costs and saves valuable space in the piping system.