Double Block & Bleed Ball Valve: A Reliable Choice for Safety

In the complex piping systems of modern industry, valves play a crucial role in controlling fluid flow, directly affecting the safety and efficiency of the entire system. The DBB (Double Block & Bleed) ball valve, an innovative valve design, stands out among numerous industrial fields with its unique structure and superior performance, becoming an essential component in piping systems. This article will delve into the structural characteristics, working principles, advantages, and applications of the DBB ball valve, as well as a comparative analysis with the DIB ball valve, to provide valuable references for professionals in related industries.

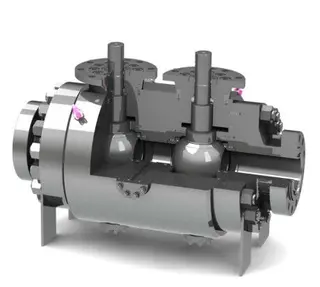

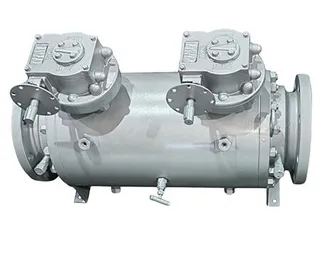

Structural Composition of the DBB Ball Valve

The structural design of the DBB ball valve is both ingenious and complex, primarily consisting of two spheres, bearings, connecting devices, seals, and actuating mechanisms. Among these, the connecting device is the core component of the entire Double Block & Bleed ball valve. It comprises a flow passage and two T-shaped connecting pipes, which are connected to the two spheres respectively. This unique connection allows the two spheres to fit tightly together when the valve is closed, forming a completely shut state and ensuring that fluid cannot pass through. When the valve is opened, the two spheres rotate 90 degrees to the sides, connecting the front and rear pipes and allowing fluid to flow smoothly. This structural design not only ensures the valve's sealing performance but also enhances the efficiency of fluid passage, reducing resistance in the pipes.

Working Principle of the DBB Ball Valve

The working principle of the Double Block & Bleed ball valve is simple yet efficient. When the valve is in the closed position, the two spheres fit tightly together, with the sealing surfaces of the spheres completely mating with the valve seats, effectively preventing fluid flow. This tight fit enables the valve to withstand high pressure when closed, ensuring system integrity. When the valve needs to be opened, the two spheres rotate 90 degrees to the sides, connecting the flow passage to the pipes and allowing fluid to enter from one direction and exit from the other. This rotation is driven by pneumatic or electric means, ensuring accuracy and efficiency in valve operation. Additionally, the DBB ball valve is equipped with an automatic venting device that prevents abnormal pressure buildup in the valve cavity after the valve is fully closed and checks the effectiveness of the valve, further enhancing system safety.

Advantages and Applications of the DBB Ball Valve

The DBB ball valve was designed to replace the complex configurations of multiple valves in traditional piping systems, thereby reducing leakage points and quickly achieving discharge and shut-off functions. This design not only simplifies the installation process and reduces pipeline system pressure but also facilitates the cleaning and maintenance of instruments, lowering costs. The valve stem of the Double Block & Bleed ball valve features a bottom-mounted design with a back-seal structure that includes a sealing washer. The sealing force of the back-seal increases with the rise in cavity medium pressure, ensuring the stem's sealing effectiveness. Even in cases of abnormal pressure buildup in the cavity, the stem will not be ejected. Moreover, the packing uses a well-designed V-shaped structure that effectively converts the internal medium pressure of the cavity and the tightening force of the external gland into the sealing force of the stem, further enhancing the valve's sealing performance.

These advantages make the DBB ball valve widely used in various industrial fields. It is extensively applied in hydraulic piping systems across industries such as power generation, petrochemicals, metallurgy, marine engineering, oil and gas, coal gas, and pharmaceuticals. In these fields, the DBB ball valve not only effectively controls fluid flow but also quickly cuts off fluid in emergency situations to prevent accidents. For example, in the petrochemical industry, the DBB ball valve is used to control the transportation of oil and natural gas, ensuring the safe operation of pipeline systems. In marine engineering, it controls the flow of seawater to prevent corrosion of equipment. In the pharmaceutical industry, it controls the production process of medicines, ensuring product quality and safety.

Comparative Analysis of DBB and DIB Ball Valves

In the industrial valve sector, both DBB and DIB ball valves are common types. They both feature a single-piece structure with dual valve seat sealing surfaces, but there are some differences in their specific functions and applications. According to Appendix B of API 6D, the standard definition of a DIB valve is a single-piece valve with two valve seat sealing surfaces. When in the closed position, the valve seats can independently isolate (seal) the medium pressure from both sides (the flow passage and the valve cavity), and the medium in the valve cavity between the valve seat sealing surfaces has a venting passage. DIB valves can be further divided into two types: DIB-1 and DIB-2. DIB-1 features dual bi-directional sealing (i.e., dual piston valve seats), while DIB-2 has one uni-directional sealing (single piston valve seat) and one bi-directional sealing (dual piston valve seat).

Compared to DIB ball valves, the DBB ball valve has a unique dual-block and venting function. This function allows the DBB ball valve to block the medium pressure from both the upstream and downstream ends of the valve simultaneously when closed, and the medium in the valve cavity between the valve seat sealing surfaces has a venting passage. This means that the DBB ball valve can stop the flow of fluid on both sides of the valve simultaneously when closed, whereas a DIB ball valve can only independently isolate the medium pressure from both sides. Additionally, the bi-directional sealing of a DBB ball valve is different from the bi-directional sealing of its valve seats. A bi-directional ball valve may consist of two single piston valve seats, one single piston valve seat and one dual piston valve seat, or two dual piston valve seats. Therefore, when selecting a valve, it is necessary to determine whether to use a DBB or DIB ball valve based on the specific working conditions and requirements.

Safety Features of the DBB Ball Valve

In addition to its structural and functional advantages, the Double Block & Bleed ball valve also has multiple safety features to ensure safe operation in various complex working conditions. For example, according to user requirements, the ball valve can be designed with a fire-resistant structure. In the event of a fire that damages the sealing ring, all sealing parts of the ball valve can form a metal-to-metal hard seal structure, effectively preventing the spread of the medium and stopping the fire from spreading. Moreover, for valves installed outdoors, to prevent unauthorized personnel from operating them, and for valves in locations with significant vibrations where the handle may be struck and accidentally operated, there are no locking holes in the fully open or fully closed positions. If necessary, a lock can be added to serve as a safety precaution. The ball valve can also be designed with an anti-static structure, which involves placing conductive springs between the sphere and the stem, and between the stem and the valve body. This allows static electricity generated during the valve's operation to be conducted through the static electricity channel into the pipeline and then into the ground, achieving the purpose of eliminating static electricity. These safety features enable the DBB ball valve to operate safely and reliably in flammable, explosive, and other hazardous environments.

Maintenance and Care of the DBB Ball Valve

To ensure the long-term stable operation of the DBB ball valve, regular maintenance and care are essential. The maintenance of the DBB ball valve is relatively simple and convenient. Its valve body and plug are designed with a reduced diameter, which helps to reduce costs. The inner cavity of the valve body is coated with hard chrome, and the sealing areas are hard and smooth. This design ensures that there is no contact between the valve body sealing surface and the slide sealing surface during the valve's operation, resulting in no friction or wear on the sealing surfaces, a longer valve lifespan, and lower operating torque. Additionally, when maintenance is required, there is no need to remove the valve from the pipeline. Simply remove the bottom cover of the valve and replace a pair of slides, making maintenance very convenient. This design not only reduces maintenance time and costs but also improves system operational efficiency.

Conclusion

The DBB ball valve, with its unique structural design, efficient working principle, wide range of applications, and superior safety features, plays a vital role in industrial piping systems. It not only effectively controls fluid flow but also ensures the safe operation of the system under various complex working conditions. Compared to DIB ball valves, the Double Block & Bleed ball valve has a unique dual-block and venting function, which better meets the special needs of different industrial fields. When selecting a valve, it is important to determine whether to use a DBB or DIB ball valve based on specific working conditions and requirements to ensure the best performance and safety of the system. With the continuous development of industrial technology, the DBB ball valve is sure to find applications in more fields, providing strong support for the safety and efficiency of industrial production.

Send your message to this supplier

Related Articles from the Supplier

Related Articles from China Manufacturers

What are Double Block and Bleed Ball Valves?

- Dec 27, 2024

Double Block & Bleed Valves

- Feb 27, 2023

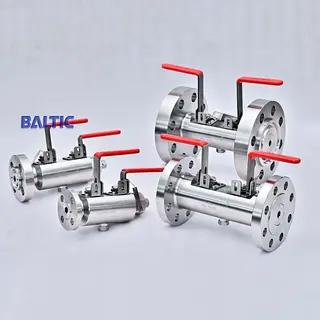

Double Block & Bleed Valves Manufactured by Baltic

- Mar 07, 2023

DOUBLE BLOCK & BLEED VALVE

- Apr 28, 2025

Double Block and Bleed Valves

- Apr 29, 2025

Related Products Mentioned in the Article

Supplier Website

Source: https://www.valvepackingsealkits.com/news/double-block-bleed-ball-valve-a-reliable-choice-for-safety.html