Comprehensive Guide to Metal Jacketed Gaskets

In the industrial field, sealing of various equipment and pipelines is of vital importance, as it directly affects production safety, efficiency, and product quality. As a traditional sealing material, metal jacketed gaskets stand out among many sealing solutions due to their unique properties and wide applications. This article will provide an in-depth discussion on the structure, materials, performance, applications, and usage considerations of metal jacketed gaskets, helping you better understand this important industrial sealing product.

Definition and Structure of Metal Jacketed Gaskets

A metal jacketed gasket is a composite-type gasket composed of an inner non-metallic material and an outer metal sheet. The inner non-metallic materials typically include flexible graphite, polytetrafluoroethylene (PTFE), asbestos-rubber sheets, ceramic fibers, etc., which have good heat resistance and compressibility. The outer metal sheet is wrapped around the non-metallic material through a specific cold-working process, providing enhanced strength, corrosion resistance, and high-temperature performance.

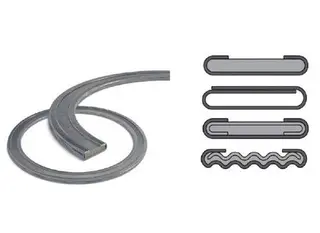

According to the cross-sectional shape of the gasket, metal jacketed gaskets are usually divided into flat type jacketed gaskets and corrugated type jacketed gaskets.

- Flat jacketed gaskets (F-type): Simple in structure, suitable for flange sealing under general working conditions.

- Corrugated jacketed gaskets (C-type): Have better elasticity and sealing performance, capable of adapting to more complex working conditions and higher pressure requirements. The corrugated structure increases gasket resilience, allowing it to maintain a good seal even when the flange surface is not completely flat.

Materials of Metal Jacketed Gaskets

The material selection for metal jacketed gaskets is very broad and can be customized according to different working conditions and medium requirements.

The outer metal material usually includes tinplate, stainless steel (such as 304, 316), copper, aluminum, etc. These metals have different corrosion resistance, heat resistance, and strength characteristics, capable of meeting the demands of various industrial environments.

The inner non-metallic filler includes flexible graphite, asbestos, non-asbestos materials, ceramic fibers, polytetrafluoroethylene, etc.

- Flexible graphite: Excellent high-temperature resistance and chemical stability, suitable for high-temperature and high-pressure conditions.

- Asbestos-rubber sheets: Good pressure resistance and certain heat resistance, but their use is limited due to asbestos content.

- Non-asbestos materials: Environmentally friendly alternatives, with good heat and pressure resistance.

- Ceramic fibers: Extremely high-temperature resistance, suitable for ultra-high-temperature environments.

- Polytetrafluoroethylene (PTFE): Good chemical stability and temperature resistance, suitable for sealing corrosive media.

Performance Characteristics of Metal Jacketed Gaskets

- High Strength and Corrosion Resistance: The outer metal sheet provides the gasket with high strength and good corrosion resistance. Metals such as stainless steel, copper, and aluminum have high mechanical strength, capable of withstanding large pressures and tensile forces, ensuring gasket stability in high-pressure environments. At the same time, these metals also have good corrosion resistance, able to resist the erosion of various chemical media, extending the service life of the gasket.

- Excellent Sealing Performance: Metal jacketed gaskets combine the advantages of metal and non-metal materials, providing excellent sealing performance. The inner non-metallic materials, such as flexible graphite and ceramic fibers, have high resilience and good compressibility, allowing good sealing at relatively low pressures. Even when the flange surface is not completely flat, the gasket can fill gaps through elastic deformation, achieving reliable sealing.

- Adaptability to Various Working Conditions: Metal jacketed gaskets are suitable for a variety of working conditions, including flange sealing for heat exchangers, pressure vessels, pumps, valves, and pipelines under medium and low pressures. They have a wide operating temperature range, from low to high temperatures (flexible graphite can withstand up to 650°C, ceramic fiber can withstand above 1200°C), meeting the requirements of different media and environments. In addition, metal jacketed gaskets can be manufactured in various shapes according to sealing structure requirements, such as oval, square-ribbed, or more complex shapes, to suit different equipment sealing needs.

- Easy Installation and Maintenance: The installation of metal jacketed gaskets is relatively simple: place the gasket between the flanges and tighten the bolts evenly. Due to their good overall rigidity, they are not easily damaged or deformed, maintaining good sealing performance even under frequent disassembly. Compared with non-metallic soft gaskets, metal jacketed gaskets are less prone to sticking to or corroding the flange sealing surface, reducing maintenance costs and replacement frequency.

Applications of Metal Jacketed Gaskets

Due to their excellent performance and wide range of applications, metal jacketed gaskets are widely used in industrial fields. The main applications include:

- Heat Exchangers: Heat exchangers are common equipment in industrial production, used for the transfer and exchange of heat. Metal jacketed gaskets are suitable for flange sealing in heat exchangers, capable of withstanding high-temperature and high-pressure conditions, ensuring the safety and stability of the heat exchange process. For example, in large fertilizer plant waste-heat boilers, metal jacketed gaskets with outer rings can prevent leakage at full load, and under partial load, adding flexible graphite sheets on both sides of the gasket can still maintain good sealing.

- Pressure Vessels: Pressure vessels are used to store and process various media, widely applied in chemical, petroleum, pharmaceutical, and other industries. Metal jacketed gaskets are suitable for flange sealing of large-diameter pressure vessels (such as heat exchangers, reactors, etc.), capable of withstanding medium- and low-pressure working conditions, pressure, and temperature variations, ensuring the safe operation of pressure vessels.

- Pumps, Valves & Pipelines: In pumps, valves, pipelines, and flange sealing of various equipment handling different media, metal jacketed gaskets also play an important role. Their excellent sealing performance and corrosion resistance can effectively prevent medium leakage, ensuring the normal operation of equipment. For example, stainless steel gaskets with flexible graphite can be used for gas media at 14.7 MPa, for liquids at 30 MPa, with temperature ranges from -190°C to 600°C, and for acidic media up to 9 MPa and 200°C.

- Other Equipment: Metal jacketed gaskets can also be applied to cylinder heads of internal combustion engines and compressors, cast iron flanges, cylinder heads, boilers, and other equipment. Their excellent performance allows them to adapt to various complex working conditions and media requirements, providing reliable sealing for industrial production.

Usage Considerations for Metal Jacketed Gaskets

Although metal jacketed gaskets have many advantages, certain considerations should be observed during use to ensure sealing performance and service life:

1. Flange Surface Requirements

The sealing effect of a metal jacketed gasket largely depends on the flatness and cleanliness of the flange surface. Flange surfaces should be flat, smooth, and free of obvious unevenness, scratches, or corrosion. Before installing the gasket, carefully inspect the flange surface, remove oil, rust, and other impurities, and ensure the flange surface is clean and flat. For flanges with high roughness, external graphite sheets or other measures can be used to improve sealing performance.

2. Installation and Tightening

When installing a metal jacketed gasket, ensure the gasket is closely fitted to the flange sealing surface to avoid misalignment or folds. When tightening bolts, use a symmetrical and uniform approach, gradually increasing the tightening force to avoid local over-tightening or looseness. The tightening force should be adjusted according to gasket material, working conditions, and design requirements to ensure proper sealing under appropriate pressure. Attention should also be paid to avoiding over-tightening, which may damage the gasket or flange.

3. Temperature and Pressure Control

The working temperature and pressure range of the metal jacketed gasket should be strictly controlled within the design range. Different gasket materials have different temperature and pressure tolerances, such as flexible graphite up to 650°C and ceramic fiber above 1200°C. During use, select appropriate gasket materials according to actual working conditions, and ensure temperature and pressure do not exceed the gasket’s limits. If conditions change, promptly adjust gasket selection or take protective measures.

4. Regular Inspection and Maintenance

During equipment operation, regularly check the sealing condition of the metal jacketed gasket and promptly address leakage issues. For frequently disassembled equipment, monitor gasket wear and replace damaged gaskets in time. Maintain clean flanges and gaskets to prevent corrosion and damage caused by impurities and chemicals. Regular maintenance can extend gasket service life, improving equipment efficiency and safety.

Conclusion

As a traditional sealing material, metal jacketed gaskets have gained wide industrial application due to their unique structure and excellent performance. They combine the advantages of metal and non-metal materials, offering high strength, excellent sealing performance, corrosion resistance, and adaptability to various working conditions. By paying attention to flange surface requirements, installation and tightening, temperature and pressure control, and regular inspection and maintenance, metal jacketed gaskets can provide reliable sealing for industrial equipment.

Send your message to this supplier

Related Articles from the Supplier

Comprehensive Guide to Metal Jacketed Gaskets

- Jan 10, 2026

A Comprehensive Guide to Spiral Wound Metal Gaskets

- May 14, 2025

A Comprehensive Guide to Bellows Sealed Globe Valves

- Jun 19, 2025

A Comprehensive Guide to Valve Gaskets Installation

- Jul 17, 2025

Electric V-Type Ball Valves: A Comprehensive Guide

- Jul 16, 2025

Related Articles from China Manufacturers

How to Choose the Right Pump: A Comprehensive Guide

- Sep 20, 2025

Comprehensive Guide to Forging Cleaning Methods

- Dec 11, 2024

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.valvepackingsealkits.com/news/comprehensive-guide-to-metal-jacketed-gaskets.html