Double Block & Bleed Ball Valve, 1/2-24 Inch, 150-3000 LB

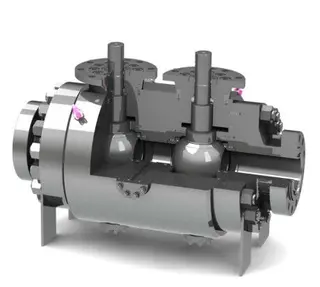

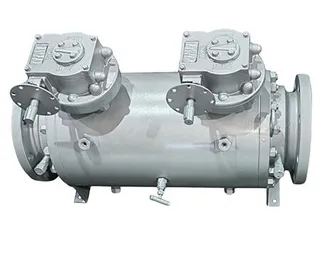

Product Name: Double Block and Bleed Ball Valve

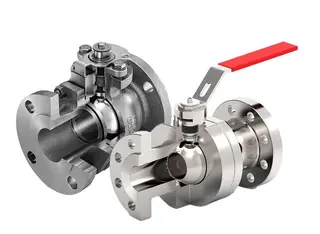

Port size: 1/2-24 Inch (DN15-DN600)

Pressure: Class 150-3000 LB, 3000-15000 PSI

Design Standard: EEMUA 182, ASME B16.34

Body material: ASTM A105, A350 LF2, A182 F304, F316, F316L, etc

Connection: Flanged * Flanged, Flanged * Threaded

Medium: Water, Steam, Oil, Gas, etc.

Temperature Range: -46°C to 350°C

Test and Inspection: EEMUA 182, API 598

Key Features of Double Block and Bleed (DBB) Ball Valves

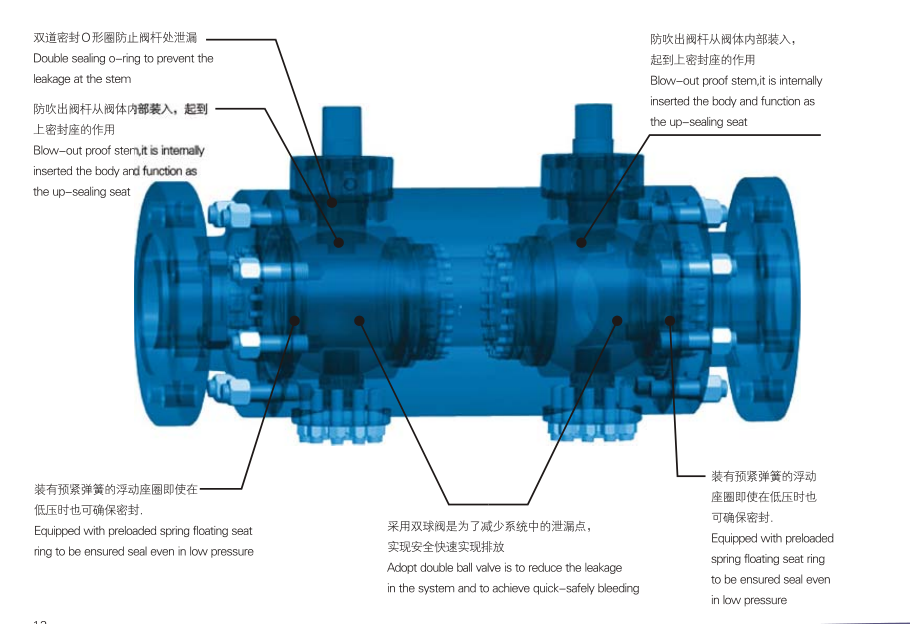

Integrated Valve Solution: Combines two isolation balls and a bleed valve in a single unit, reducing the need for multiple valves and simplifying installation.

Space and Cost Saving: Minimizes installation time, footprint, and system cost compared to traditional multi-valve setups.

Enhanced Safety and Leak Control: Provides double sealing against pressure from both sides with a bleed function to safely vent the cavity between seats, reducing leakage paths and environmental hazards.

Trunnion and Floating Designs: Available in trunnion-mounted (for high pressure and durability) and floating ball versions.

Pressure Relief and Maintenance Ease: Includes needle valves for controlled pressure release and venting, facilitating instrument maintenance and cleaning.

Fast and Reliable Operation: Enables quick isolation and venting, reducing downtime during maintenance.

Applications: Commonly used in instrumentation, oil & gas, chemical, and power industries where compact, safe isolation and bleed are required.

Send your message to this supplier

Related Articles from the Supplier

How to Install Your Pneumatic Ball Valve?

- Sep 15, 2025

Electric V-Type Ball Valves: A Comprehensive Guide

- Jul 16, 2025

Common Ball Valve Leakage Types and Their Solutions

- Jul 19, 2025

Related Articles from China Manufacturers

Monoflange, Double Block & Bleed Valves

- Nov 25, 2021

What are Double Block and Bleed Ball Valves?

- Dec 27, 2024

Introduction to Double Block and Bleed Valve

- Feb 26, 2019

Double Block & Bleed Valves

- Feb 27, 2023

What is Double Block and Bleed Valves ?

- May 08, 2019

Related Products Mentioned in the Article

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.valvepackingsealkits.com/double-block-bleed-ball-valve-1-2-24-inch-150-3000-lb.html