What Is The Difference Between Steel Elbow And Pipe Bend?

Do you know what the difference is between steel elbow and pipe bend? Let's get to know it.

Steel elbow

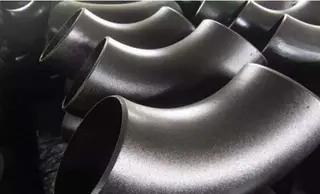

The most commonly used is seamless elbow, which is divided into long radius elbow and short radius elbow. The long radius bend is the most commonly used elbow, and its application is also very extensive.

Elbows are distinguished according to the specifications:

Small and medium-sized seamless elbows are seamless elbows. At present, the maximum diameter of domestic seamless elbows is 40″, i.e. Φ 1020, that is, within the scope of DN 15-dn 1000. Large-size steel plate butt welded elbows are generally used. This process can also be divided into long radius elbow and short radius elbow, and the involved specifications is around: DN500-DN2500. The use of steel bend is more special than that of elbow, but the two kinds of pipe generally do not conflict with each other.

Differentiation of steel bends:

According to the distinction of R: r is the radius, usually starting with 3D and ending until the size required by the working conditions. That is, R is infinite, as long as it exceeds 3D. According to the angle, the angle is not limited. There are also differences between seamless and seam. Generally, small seamless specifications are used, and large sizes of joints are used, such as spiral welding. According to the production process: medium frequency hot bending process, seamless push technology, and CNC processing technology.

Difference between elbow and bend:

Elbow and bend are introduced in the above contents. What's the difference between them? There must be a difference. So what is the main difference between them?

1. First of all, the process:

The process of seamless elbow is hot pushing, cold pressing and hot pressing, while the bending process is medium frequency bending, hot pressing and numerical control bending. Among them, carbon steel is the most commonly used elbow in pressure pipeline. Alloy steel is hot pushing. Stainless steel is cold pushing, and the most commonly used process of elbow is medium frequency bending.

2. The difference of scour strength

Elbow and bend itself R are different. R is a position to control the length of elbow and bend. The erosion intensity of small R through medium is certainly much greater than that of large R, that is to say, the scouring strength of 1D elbow is not as good as that of 1.5D elbow. The erosion strength of 1.5D elbow is lower than that of bend, and bend is more resistant to erosion and wear than elbow.

3. There is also a special case, such as bridges. It is necessary to use a long-span bend to cross the pipe. At this time, elbows can not be used, and bends are also used in general heat pipes.

With the help of bending in different industries, the bending strength can be further reduced in different industries. Pipe bend is widely used in electric power, petroleum, navigation, chemical industry and other fields. It is mainly used in oil transportation, natural gas transportation and infusion. It plays an important role in aircraft and its engine. The above specifically introduces the differences between steel elbow and bend and how to distinguish them. Hope the above contents could help you better understand and use elbows and bends.

Steel elbow

The most commonly used is seamless elbow, which is divided into long radius elbow and short radius elbow. The long radius bend is the most commonly used elbow, and its application is also very extensive.

Elbows are distinguished according to the specifications:

Small and medium-sized seamless elbows are seamless elbows. At present, the maximum diameter of domestic seamless elbows is 40″, i.e. Φ 1020, that is, within the scope of DN 15-dn 1000. Large-size steel plate butt welded elbows are generally used. This process can also be divided into long radius elbow and short radius elbow, and the involved specifications is around: DN500-DN2500. The use of steel bend is more special than that of elbow, but the two kinds of pipe generally do not conflict with each other.

Differentiation of steel bends:

According to the distinction of R: r is the radius, usually starting with 3D and ending until the size required by the working conditions. That is, R is infinite, as long as it exceeds 3D. According to the angle, the angle is not limited. There are also differences between seamless and seam. Generally, small seamless specifications are used, and large sizes of joints are used, such as spiral welding. According to the production process: medium frequency hot bending process, seamless push technology, and CNC processing technology.

Difference between elbow and bend:

Elbow and bend are introduced in the above contents. What's the difference between them? There must be a difference. So what is the main difference between them?

1. First of all, the process:

The process of seamless elbow is hot pushing, cold pressing and hot pressing, while the bending process is medium frequency bending, hot pressing and numerical control bending. Among them, carbon steel is the most commonly used elbow in pressure pipeline. Alloy steel is hot pushing. Stainless steel is cold pushing, and the most commonly used process of elbow is medium frequency bending.

2. The difference of scour strength

Elbow and bend itself R are different. R is a position to control the length of elbow and bend. The erosion intensity of small R through medium is certainly much greater than that of large R, that is to say, the scouring strength of 1D elbow is not as good as that of 1.5D elbow. The erosion strength of 1.5D elbow is lower than that of bend, and bend is more resistant to erosion and wear than elbow.

3. There is also a special case, such as bridges. It is necessary to use a long-span bend to cross the pipe. At this time, elbows can not be used, and bends are also used in general heat pipes.

With the help of bending in different industries, the bending strength can be further reduced in different industries. Pipe bend is widely used in electric power, petroleum, navigation, chemical industry and other fields. It is mainly used in oil transportation, natural gas transportation and infusion. It plays an important role in aircraft and its engine. The above specifically introduces the differences between steel elbow and bend and how to distinguish them. Hope the above contents could help you better understand and use elbows and bends.

Send your message to this supplier

Related Articles from the Supplier

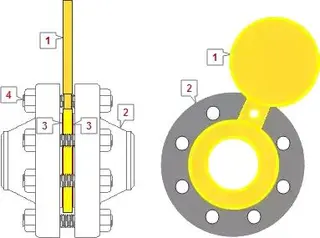

What Is Spectacle Blind Flange?

- Aug 08, 2020

What Are The Testing Standards of Carbon Steel?

- Oct 26, 2020

What Are Galvanized Square Tubes?

- Jan 12, 2021

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.pipessteel.com/news/what-is-the-difference-between-steel-elbow-and-pipe-bend.html