Why Aluminum Bronze Ball Valves Are the Ideal Choice for Corrosive Applications

Introduction

In the world of industrial fluid control, the choice of valve material plays a critical role in ensuring system reliability, performance, and longevity. Among the various materials used in valve construction, aluminum bronze stands out as one of the most durable and corrosion-resistant alloys available. The aluminum bronze ball valve combines the superior strength of copper alloys with the exceptional corrosion resistance of aluminum, making it an ideal solution for harsh operating conditions found in marine, chemical, and industrial environments.

This article explores everything you need to know about aluminum bronze ball valves — including their construction, working principles, performance advantages, and diverse industrial applications. Whether you are selecting valves for a seawater pipeline, an oil refinery, or a power generation facility, understanding the unique properties of aluminum bronze can help you make a more informed decision.

What Is an Aluminum Bronze Ball Valve?

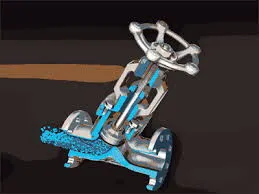

An aluminum bronze ball valve is a type of valve that regulates fluid flow using a spherical ball with a hole (called a bore) through its center. The valve is operated by rotating the ball—typically through a quarter-turn (90°)—using a handle, gear, or actuator. When the bore is aligned with the pipeline, fluid flows freely through the valve. When the ball is turned perpendicular to the pipeline, the flow is blocked completely.

Unlike standard stainless steel or brass valves, aluminum bronze ball valves are made primarily from aluminum bronze alloy, a family of copper-based materials that contain 5–11% aluminum by weight, with small additions of iron, nickel, manganese, and sometimes silicon. The inclusion of aluminum significantly enhances the alloy’s strength and corrosion resistance, allowing it to withstand highly demanding environments such as seawater exposure or corrosive chemical processes.

All aluminum bronze ball valves undergo non-destructive testing (NDT)—such as ultrasonic, dye penetrant, and radiographic inspections—to ensure material integrity and manufacturing quality. Additionally, each valve is pressure-tested before leaving the factory to verify its sealing performance and operational reliability.

Composition and Characteristics of Aluminum Bronze

Aluminum bronze alloys are unique among copper-based materials because of their high tensile strength, excellent wear resistance, and exceptional resistance to corrosion and erosion. The key chemical and physical properties that make aluminum bronze a preferred choice for valve manufacturing include:

High Strength: Comparable to medium carbon steel, aluminum bronze offers outstanding mechanical strength, enabling it to handle high-pressure applications without deformation or wear.

Corrosion Resistance: The aluminum content forms a thin, adherent oxide film on the metal surface, providing excellent resistance to oxidation, seawater corrosion, and most chemical environments.

Resistance to Cavitation and Erosion: Ideal for systems involving high-velocity or turbulent fluids, aluminum bronze resists pitting and cavitation damage better than most other non-ferrous metals.

Non-Sparking and Non-Magnetic Properties: Useful in applications where spark-free operation is critical, such as oil refineries or explosive environments.

Longevity and Reliability: Due to its resistance to corrosion and mechanical wear, aluminum bronze valves typically have a longer service life with reduced maintenance requirements.

Working Principles of an Aluminum Bronze Ball Valve

The aluminum bronze ball valve operates on a simple but highly effective principle of flow control through rotational movement. Here’s a step-by-step overview of its operation:

Structure Overview

The valve body includes an inlet and outlet port, with a ball-shaped disc housed in between. The ball contains a central bore that allows fluid to pass through.

Flow Control

When the ball’s bore aligns with the flow path, the valve is open, and fluid flows through with minimal resistance. When the ball is rotated 90°, the bore becomes perpendicular to the flow path, sealing off the passage and stopping the flow completely.

Operation

The ball is connected to a stem, which extends through the top of the valve and is linked to a handle, gear, or actuator. Rotating the stem turns the ball, switching between open and closed positions. Depending on system requirements, operation can be manual, electric, or pneumatic.

Sealing Mechanism

When closed, the ball presses tightly against the valve seat, ensuring a bubble-tight seal that prevents leakage even under high pressure. The design allows for reliable performance in both on-off and throttling applications.

Advantages of Aluminum Bronze Ball Valves

The growing popularity of aluminum bronze ball valves in industrial and marine applications is due to their unique combination of properties. Below are some of the key advantages:

1. Exceptional Corrosion Resistance

One of the most valuable features of aluminum bronze is its superior resistance to seawater and saline environments. The aluminum oxide film that forms on the surface acts as a natural barrier against corrosion, making these valves ideal for offshore platforms, desalination plants, and shipboard systems.

2. High Mechanical Strength

Aluminum bronze maintains impressive tensile and yield strength even under elevated temperatures. This allows the valves to operate effectively in high-pressure systems, where mechanical stress is a major concern.

3. Excellent Erosion and Cavitation Resistance

When used in high-velocity flow systems or abrasive environments, aluminum bronze offers outstanding resistance to erosion and cavitation—problems that often degrade other materials like brass or cast iron.

4. Long Service Life

Due to its robustness and corrosion resistance, aluminum bronze ball valves typically require minimal maintenance and offer a long operational lifespan, which translates into reduced downtime and cost savings over time.

5. Thermal and Electrical Conductivity

The alloy’s copper base ensures good thermal and electrical conductivity, making it suitable for applications involving heat transfer or electrical grounding requirements.

6. Safety in Hazardous Environments

The non-sparking characteristic of aluminum bronze makes it particularly safe for use in explosive or flammable settings such as oil refineries, gas pipelines, or chemical plants.

Applications of Aluminum Bronze Ball Valves

Aluminum bronze ball valves are used in a wide range of industries where reliability, corrosion resistance, and mechanical durability are essential. Some of the most common application sectors include:

1. Marine and Offshore Industry

These valves are extensively used in seawater cooling systems, ballast systems, bilge pumping systems, and fire-fighting pipelines on ships and offshore oil platforms. Their ability to resist saltwater corrosion ensures safe and long-lasting performance.

2. Chemical and Petrochemical Plants

In chemical processing facilities, aluminum bronze ball valves are used to handle corrosive fluids and chemical media that would rapidly degrade standard steel or iron valves.

3. Oil and Gas Industry

From upstream drilling operations to downstream refining, aluminum bronze ball valves are utilized in systems that require strong, non-sparking, and corrosion-resistant components capable of handling harsh chemicals and high pressures.

4. Power Generation

In both conventional and renewable energy plants, aluminum bronze valves are used in cooling water circuits, condensers, and auxiliary pipelines exposed to varying temperature and pressure conditions.

5. Mining and Mineral Processing

The rugged construction of aluminum bronze ball valves allows them to withstand abrasive slurries and corrosive liquids encountered in mining operations.

6. Water Treatment and Desalination

Due to their exceptional resistance to chlorides and saline water, aluminum bronze valves are a preferred choice in water treatment facilities and seawater desalination systems.

7. Pulp and Paper Industry

In this sector, aluminum bronze ball valves are used for managing water, chemicals, and steam in processes that require durable, corrosion-resistant materials.

Manufacturing and Quality Control

The performance of an aluminum bronze ball valve depends heavily on the quality of its materials and precision manufacturing processes. Reputable manufacturers follow strict international standards such as API 6D, ASME B16.34, and EN 12266 to ensure product reliability.

Typical production processes include:

Precision Casting or Forging: To create a robust and defect-free valve body.

Machining and Surface Treatment: Achieving exact tolerances for smooth operation and leak-free sealing.

Non-Destructive Testing (NDT): Ultrasonic, magnetic particle, and dye penetrant tests verify material soundness.

Pressure and Leak Testing: Each valve undergoes hydrostatic and pneumatic tests to ensure zero leakage under rated pressure.

Final Inspection: Dimensional checks, marking verification, and documentation review before shipment.

These rigorous quality control measures guarantee that every aluminum bronze ball valve meets the highest standards of safety, reliability, and performance.

Maintenance and Service Life

One of the main benefits of aluminum bronze ball valves is their low maintenance requirement. However, like all industrial equipment, periodic inspection and servicing help extend their lifespan. Recommended practices include:

Regular Visual Inspection: Checking for signs of corrosion, leaks, or mechanical wear.

Cleaning: Removing deposits or scale that might hinder proper valve movement.

Lubrication: Applying suitable lubricants to the stem and seals, especially in high-temperature environments.

Seal Replacement: Periodic replacement of soft seats or O-rings to maintain sealing performance.

When maintained properly, an aluminum bronze ball valve can easily exceed 20 years of service life, even in aggressive environments.

Conclusion

The aluminum bronze ball valve is a robust and reliable solution for industries that demand strength, corrosion resistance, and long-term durability. Its unique combination of mechanical and chemical properties allows it to perform efficiently in some of the most challenging environments — from marine applications and offshore oil platforms to chemical plants and power generation systems.

By offering outstanding resistance to seawater corrosion, high pressure, and wear, aluminum bronze ball valves ensure consistent and safe operation while minimizing maintenance costs. For engineers and procurement professionals looking for a long-lasting, cost-effective solution to fluid control challenges, aluminum bronze stands as one of the best material choices available today.

Send your message to this supplier

Related Articles from the Supplier

Why Choose Forged Flanged Ball Valves?

- Mar 29, 2024

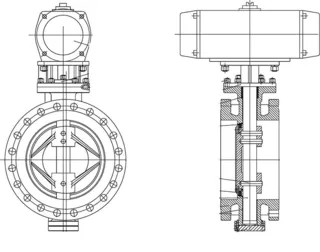

Why Use Pneumatic Actuator Butterfly Valves?

- Jun 05, 2024

Why Choose Refurbishing and Repairing Valves?

- Aug 14, 2024

Related Articles from China Manufacturers

Why Use Forged Aluminum Hitch Ball Mount for Towing

- Jun 27, 2024

Why is Forged Aluminum Suitable for Handlebar Risers

- Sep 09, 2024

Why Improve the Surface Finish of Aluminum Forgings

- Jun 20, 2024

Related Products Mentioned in the Article

Supplier Website

Source: https://www.mfrsvalve.com/news/why-aluminum-bronze-ball-valves-are-the-ideal-choice-for-corrosive-applications.html