What Are Stainless Steel Globe Valves? Design, Working Principle, and Applications

Introduction

Stainless steel globe valves remain one of the most trusted and widely applied valve types in modern industry, valued for their precise throttling capability, dependable shutoff performance, and exceptional resistance to corrosion and temperature extremes. From oil and gas processing units to power plants, chemical facilities, water treatment systems, and marine installations, these valves play a critical role in regulating fluid flow under challenging operating conditions. As industrial systems grow more automated and performance expectations increase, stainless steel globe valves continue to evolve in design, materials, and manufacturing technology to meet higher standards of efficiency, reliability, and safety.

This article explores how stainless steel globe valves work, their structural features, material advantages, design variations, performance characteristics, and their importance across key industries.

Working Principle of Stainless Steel Globe Valves

At the core of a globe valve's operation is a linear motion mechanism that provides accurate and repeatable control of flow. The valve consists of a movable disc (or plug) and a stationary seat ring inside a pressure-retaining body. Fluid enters the valve, flows through an orifice between the disc and seat, and exits after a directional change within the body.

The disc is connected to a threaded stem. When the handwheel or actuator rotates the stem, it moves the disc vertically along the valve's central axis:

- Opening: The disc lifts away from the seat, enlarging the flow path.

- Throttling: Partial stem travel positions the disc at a controlled distance from the seat, allowing fine adjustment of flow rate.

- Closing: The disc contacts the seat, creating a tight shutoff seal.

This straight-line motion, aligned with the seat, allows globe valves to achieve a level of throttling precision not typically possible with gate or ball valves. Because the disc approaches the seat gradually, flow can be modulated smoothly, reducing shock and minimizing system instability.

Upstream pressure often assists sealing by pushing the disc firmly against the seat when fully closed. In stainless steel globe valves, this metal-to-metal or soft-seated interface maintains sealing integrity even during temperature cycling or exposure to aggressive media.

Key Structural Components of Stainless Steel Globe Valve

A stainless steel globe valve is built from several essential components, each engineered for durability and performance:

1. Body

The body forms the pressure boundary and defines the internal flow path. Stainless steel bodies are commonly cast or forged to ensure strength and corrosion resistance. Body designs may include straight pattern (T-type), angle pattern, or Y-pattern configurations depending on flow and pressure requirements.

2. Bonnet

The bonnet encloses the stem and internal components and attaches to the body through bolted, welded, or pressure-seal connections. It provides structural rigidity and contains the stem sealing system.

3. Disc (Plug)

The disc regulates flow and provides shutoff. Designs include plug-type discs for throttling, composition discs with soft inserts for tighter sealing, and needle-style discs for fine control.

4. Seat Ring

The seat provides the sealing surface against the disc. It may be integral with the body or replaceable. Hard-facing materials such as Stellite or tungsten carbide may be applied to enhance wear resistance.

5. Stem

The stem transmits motion from the actuator or handwheel to the disc. Stainless steel stems offer strength and corrosion resistance while ensuring smooth movement.

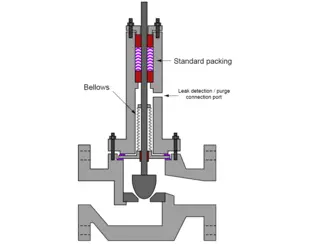

6. Packing and Gland

Packing materials such as PTFE or graphite seal around the stem to prevent leakage. The gland compresses the packing and allows adjustment during service.

7. Actuation Mechanism

Globe valves may be manually operated or automated using electric, pneumatic, or hydraulic actuators for remote or precise control.

Material Advantages of Stainless Steel

The use of stainless steel is a defining characteristic that enhances globe valve performance:

Corrosion Resistance

Austenitic stainless steels such as ASTM A351 CF8 (304) and CF8M (316) resist oxidation, chemical attack, and pitting, making them ideal for water, chemicals, and marine environments.

Temperature Tolerance

Stainless steel maintains mechanical strength at both elevated and low temperatures, enabling use in steam systems, cryogenic service, and thermal cycling conditions.

Mechanical Strength

High tensile strength allows stainless steel globe valves to withstand high pressures and mechanical stresses.

Hygienic Properties

Smooth, non-reactive surfaces support applications in food processing, pharmaceuticals, and clean water systems.

Longevity

Reduced corrosion and wear translate into longer service life and lower maintenance costs.

Common Design Variations

Stainless steel globe valves are available in multiple body and trim designs to suit different services:

Straight Pattern (T-Pattern)

The most common design, with a horizontal seat and a vertical stem. It offers excellent throttling control but higher pressure drop due to flow direction change.

Angle Pattern

The inlet and outlet are at 90 degrees. This design can reduce piping elbows and is useful where space or flow direction changes are needed.

Y-Pattern

The seat and stem are angled, providing a straighter flow path. This reduces pressure drop while maintaining good throttling capability, making it suitable for high-pressure steam systems.

Bellows-Sealed Globe Valves

Used in hazardous or high-purity systems, a metal bellows provides a hermetic seal around the stem, eliminating fugitive emissions.

Pressure-Seal Globe Valves

Designed for high-pressure and high-temperature service, these valves use internal pressure to enhance bonnet sealing.

Performance Characteristics of Stainless Steel Globe Valve

Precise Flow Control

Globe valves excel in throttling service, allowing operators to maintain stable process variables such as pressure, temperature, and flow rate.

Reliable Shutoff

When fully closed, the disc and seat create a tight seal that minimizes leakage.

Pressure Drop Considerations

Because fluid changes direction inside the valve, globe valves produce higher pressure drop than gate valves. This must be considered during system design.

Durability in Severe Service

Stainless steel construction resists erosion, corrosion, and thermal stress, enabling reliable operation in harsh environments.

Maintenance Accessibility

Many globe valves allow in-line maintenance of seats, discs, and packing without removing the valve body from the pipeline.

Industrial Applications of Stainless Steel Globe Valve

Oil and Gas

Used for flow control in refineries, offshore platforms, and gas processing plants where corrosive fluids and high pressures are common.

Power Generation

Critical in steam lines, feedwater systems, and turbine bypass systems due to their temperature resistance and throttling precision.

Chemical Processing

Handle aggressive chemicals safely thanks to stainless steel's chemical resistance.

Water and Wastewater

Control water distribution, treatment processes, and sludge systems with reliable corrosion resistance.

Marine and Offshore

Resist seawater corrosion and support ballast, cooling, and fuel systems.

HVAC and Building Services

Provide temperature and flow control in heating and cooling systems.

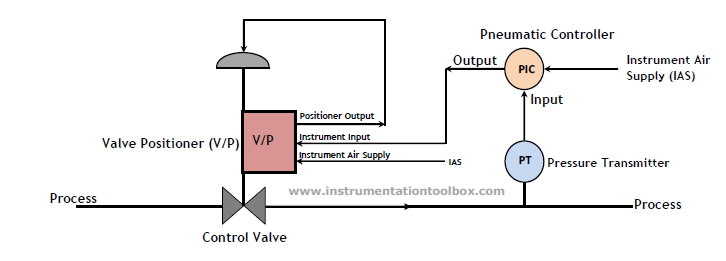

Automation and Smart Control

Modern stainless steel globe valves increasingly integrate with automated systems:

- Electric actuators for remote operation

- Pneumatic actuators for rapid response

- Positioners and sensors for accurate control

- Digital monitoring for predictive maintenance

These technologies enhance efficiency, reduce manual intervention, and improve process stability.

Installation and Maintenance Considerations for Stainless Steel Globe Valves

Proper installation and regular maintenance are critical to ensuring that stainless steel globe valves operate efficiently, safely, and with maximum longevity. Correct installation is the first step toward achieving optimal performance. Always observe the flow direction markings on the valve body to ensure the valve is installed in the proper orientation. Incorrect installation can lead to reduced flow control accuracy, increased wear, or even damage to the valve components.

When installing, care should be taken not to over-tighten the packing around the stem. Over-compression can cause excessive friction, making operation difficult and potentially damaging the valve stem. Ensuring proper alignment between the valve body and connecting pipeline is equally important, as misalignment can lead to stem binding, uneven wear, and premature failure.

Routine inspections and preventive maintenance help maintain reliable operation. Periodically check the seat surfaces, packing material, and actuator components for wear, corrosion, or leakage. Replace or service components as necessary to avoid operational issues. Lubricate moving parts according to manufacturer recommendations to reduce friction and extend service life.

By adhering to proper installation practices and a consistent maintenance schedule, operators can maximize the performance, reliability, and safety of stainless steel globe valves, ensuring stable and precise flow control throughout their operational life.

Future Trends

Advancements in manufacturing, such as precision casting, CNC machining, and advanced coatings, are improving valve performance. Emphasis on emissions control, energy efficiency, and smart plant integration is driving the development of low-leakage and digitally enabled globe valves.

Conclusion

Stainless steel globe valves combine precise control, strong sealing performance, and excellent resistance to corrosion and temperature extremes. Their versatility across industries—from energy and chemicals to water and marine applications—demonstrates their enduring importance. As industrial systems continue to demand higher efficiency, safety, and automation, stainless steel globe valves will remain a cornerstone technology for dependable and accurate flow regulation.

Send your message to this supplier

Related Articles from the Supplier

What Are the Valve’s Manufacturing Technology?

- Sep 15, 2020

What are the Manufacturing Processes for Valves?

- Apr 01, 2024

What Are Bellows Seal Globe Valves?

- Jun 26, 2024

What is a Side Entry Ball Valve?

- Nov 19, 2024

Related Articles from China Manufacturers

Related Products Mentioned in the Article

Supplier Website

Source: https://www.mfrsvalve.com/news/what-are-stainless-steel-globe-valves-design-working-principle-and-applications.html