How Cryogenic Swing Check Valves Support Safe LNG Processing and Transport

Introduction

As global energy demand continues to rise and cleaner fuels gain momentum, cryogenic technologies have become a cornerstone of modern industrial development. From liquefied natural gas (LNG) production and transport to industrial gases, aerospace, and advanced manufacturing, cryogenic processes enable the storage and handling of gases at extremely low temperatures. At the heart of these systems lies a critical component that often operates silently but plays a decisive role in safety and reliability: the cryogenic valve.

Among various cryogenic valve types, cryogenic swing check valves are essential for preventing reverse flow in pipelines operating at temperatures as low as -196°C. These valves are engineered to function reliably under extreme thermal stress, ensuring system integrity, protecting expensive equipment, and safeguarding personnel. Their importance is especially evident in LNG plants, where uninterrupted, safe, and leak-free operation is non-negotiable.

This article provides a comprehensive overview of cryogenic swing check valves, including their working principles, design features, materials, benefits, applications, and their vital role in LNG and other cryogenic industries.

Understanding Cryogenic Applications and Their Challenges

Cryogenic applications involve fluids stored and transported at temperatures far below freezing, typically below -40°C, and in many cases reaching -196°C, the boiling point of liquid nitrogen. Common cryogenic fluids include:

- Liquefied Natural Gas (LNG)

- Liquid Nitrogen

- Liquid Oxygen

- Liquid Argon

- Liquid Hydrogen

- Liquid Helium

Operating at such temperatures introduces unique challenges that conventional valves cannot withstand. Materials may become brittle, seals may lose elasticity, and thermal contraction can cause misalignment, leakage, or mechanical failure. Additionally, rapid temperature fluctuations during start-up and shutdown cycles further stress valve components.

To overcome these challenges, cryogenic valves—including swing check valves—are specifically designed with suitable materials, extended bonnets, specialized sealing systems, and precision manufacturing processes.

The Role of Cryogenic Valves in the LNG Industry

Cryogenic valves are most prominently used in the Liquefied Natural Gas (LNG) industry, which has seen rapid growth as countries transition toward lower-carbon energy sources. Natural gas is liquefied by cooling it to approximately -162°C, reducing its volume by about 600 times. This dramatic volume reduction makes long-distance transportation by ship feasible and economical.

LNG Plant Structure and Valve Requirements

A typical LNG plant consists of one or more LNG trains, each functioning as an independent unit for gas purification and liquefaction. These trains usually include:

Compression Area – where natural gas is compressed to suitable pressures

Propane Condenser Area – for pre-cooling the gas

Ethane and Methane Refrigeration Areas – for deep cryogenic cooling and liquefaction

Throughout these stages, cryogenic valves are installed in pipelines, storage tanks, loading arms, and transfer lines. Among them, check valves are crucial for ensuring one-way flow and preventing backflow that could cause pressure surges, contamination, or catastrophic system failure.

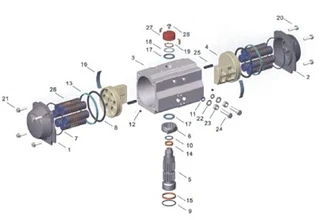

What Is a Cryogenic Swing Check Valve?

A cryogenic swing check valve is a specialized non-return valve designed to permit fluid flow in only one direction under cryogenic conditions. It uses a hinged disc that swings open when fluid flows in the correct direction and automatically closes when flow reverses or stops.

Unlike conventional check valves, cryogenic swing check valves are specifically engineered to withstand ultra-low temperatures and severe thermal cycling. Their design ensures smooth operation, reliable sealing, and long service life even in the harshest cryogenic environments.

Working Principle of Cryogenic Swing Check Valves

The operating principle of a cryogenic swing check valve is simple yet highly effective:

Forward Flow

When cryogenic fluid flows in the intended direction, the pressure pushes the disc open. The disc swings away from the seat, allowing unobstructed flow with minimal pressure drop.

Flow Reduction or Reversal

When flow decreases or reverses, gravity and back pressure cause the disc to swing back toward the seat.

Automatic Closure

The disc closes tightly against the seat, preventing reverse flow and protecting upstream equipment.

This automatic operation requires no external power or control system, making swing check valves highly reliable and ideal for safety-critical cryogenic systems.

Key Design Features for Cryogenic Service

Cryogenic swing check valves differ significantly from standard check valves due to the demanding service conditions. Several design features are essential to ensure safe and reliable operation:

Extended or Loose Bonnet Design

One of the most important features of cryogenic valves is the extended bonnet or loose bonnet design. This structure keeps the stem sealing area away from the cryogenic fluid, allowing it to remain at a higher temperature. This prevents seal freezing, maintains packing integrity, and reduces the risk of leakage.

Specialized Disc and Hinge Mechanism

The disc and hinge assembly are designed to operate smoothly despite thermal contraction. Precision tolerances ensure that the disc can swing freely without sticking or binding, even at extremely low temperatures.

Cryogenic Sealing Systems

Sealing materials must retain flexibility and sealing performance at cryogenic temperatures. Soft seats, metal-to-metal seats, or a combination of both may be used depending on application requirements.

Pressure Relief Features

Some cryogenic swing check valves incorporate pressure relief holes in the disc to prevent pressure buildup in the valve cavity during temperature changes, further enhancing safety.

Materials Used in Cryogenic Swing Check Valves

Material selection is critical for cryogenic valve performance. Materials must maintain toughness, strength, and corrosion resistance at ultra-low temperatures.

Common Body Materials

- Austenitic Stainless Steel (CF8, CF8M, CF3, CF3M)

Widely used due to excellent low-temperature toughness and corrosion resistance.

- Nickel Alloys

Used for extremely demanding applications such as liquid hydrogen or helium.

- Bronze and Aluminum Bronze

Selected for specific cryogenic and marine environments.

Internal Components

Valve discs, hinge pins, and seats are typically made from stainless steel or other cryogenically suitable alloys to ensure consistent performance and durability.

Advantages of Cryogenic Swing Check Valves

Cryogenic swing check valves offer numerous advantages that make them indispensable in low-temperature applications:

Consistent Sealing at Extreme Temperatures

These valves maintain reliable sealing performance even at temperatures approaching -196°C, ensuring leak-free operation.

Tight Shut-Off Over Long Service Life

Precision machining and high-quality materials allow cryogenic swing check valves to maintain tight shut-off throughout their operational lifespan.

Bi-Directional Sealing Capability

Some designs offer enhanced sealing performance under varying pressure conditions, adding an extra layer of safety.

Reduced Risk of Fugitive Emissions

Effective sealing and extended bonnet designs significantly reduce the risk of gas leakage, supporting environmental compliance and workplace safety.

Superior Performance During Thermal Fluctuations

Cryogenic systems often experience rapid temperature changes. Cryogenic swing check valves are designed to handle thermal expansion and contraction without loss of performance.

Robust Construction for Safety and Reliability

High-quality castings and strict quality control ensure structural integrity under both cryogenic temperatures and high pressures.

Applications of Cryogenic Swing Check Valves

Cryogenic swing check valves are used across a wide range of industries, including:

LNG Production and Export Terminals

Installed in liquefaction units, transfer lines, storage tanks, and loading systems to prevent backflow and ensure safe operation.

LNG Import and Regasification Facilities

Protect pipelines and equipment during unloading and regasification processes.

Industrial Gas Processing

Used in air separation units and gas liquefaction plants handling nitrogen, oxygen, argon, and other gases.

Petrochemical and Refining Industries

Applied in low-temperature hydrocarbon processing and storage systems.

Aerospace and Space Exploration

Essential for handling cryogenic fuels such as liquid hydrogen and liquid oxygen.

Compliance with International Standards

Cryogenic swing check valves are typically designed and manufactured in accordance with international standards, such as:

API standards for valve design and testing

BS and EN standards for cryogenic service

ISO quality management systems

Compliance ensures reliability, safety, and global acceptance in critical projects.

Importance of Quality Manufacturing and Testing

Given the critical nature of cryogenic service, quality manufacturing and rigorous testing are indispensable. Cryogenic swing check valves often undergo:

- Low-temperature testing

- Pressure and leakage testing

- Material impact testing at cryogenic temperatures

- Dimensional and functional inspections

These tests verify that the valve will perform safely and reliably in real-world cryogenic conditions.

Future Trends in Cryogenic Valve Technology

As LNG demand grows and new applications such as hydrogen energy emerge, cryogenic valve technology continues to evolve. Key trends include:

Advanced materials for even lower temperature resistance

Improved sealing technologies to further reduce emissions

Smart valve integration for monitoring and diagnostics

Enhanced designs for hydrogen and next-generation cryogenic fuels

Cryogenic swing check valves will remain a vital component as industries push the boundaries of low-temperature technology.

Conclusion

Cryogenic swing check valves play an indispensable role in modern cryogenic systems, particularly in the LNG industry where safety, reliability, and efficiency are paramount. Designed to operate at temperatures as low as -196°C, these valves ensure one-way flow, prevent dangerous backflow, and maintain tight sealing under extreme thermal stress.

Through specialized designs, carefully selected materials, and rigorous testing, cryogenic swing check valves provide consistent performance across a wide range of demanding applications—from LNG liquefaction and transport to industrial gases and aerospace systems. As global energy infrastructure continues to expand and diversify, the importance of high-quality cryogenic swing check valves will only continue to grow, supporting safer, cleaner, and more efficient industrial operations worldwide.

Send your message to this supplier

Related Articles from the Supplier

How to Overcome the Impact of Scale on Valves

- Oct 10, 2023

How to Combat Valve Corrosion?

- Mar 26, 2024

Related Articles from China Manufacturers

How do cryogenic valves work?

- Nov 01, 2019

How do cryogenic valves work?

- Nov 01, 2019

How Do Cryogenic Valves Work?

- Apr 10, 2021

How to Use Cryogenic Valves

- Oct 09, 2016

Related Products Mentioned in the Article

Supplier Website

Source: https://www.mfrsvalve.com/news/how-cryogenic-swing-check-valves-support-safe-lng-processing-and-transport.html