Comprehensive Guide to Duplex Gate Valves: Types, Materials, and Applications

Introduction

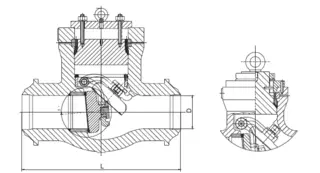

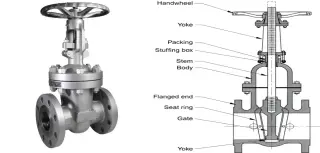

A duplex gate valve is a type of valve specifically designed to start or stop the flow of fluid in pipelines by raising or lowering a wedge, rectangular gate, or similar closure element. Unlike other valve types, the gate moves in a linear motion—either up to open the valve or down to stop flow—allowing for minimal pressure drop when fully open. The motion of the gate is controlled by a stem or shaft, which can be operated manually via a handwheel or automatically through various types of actuators.

Duplex stainless steel gate valves combine the strengths of two distinct stainless steel families: austenitic and ferritic. Austenitic stainless steel contributes excellent toughness, ductility, and weldability, while ferritic stainless steel enhances yield strength, intergranular corrosion resistance, and resistance to chloride-induced stress corrosion cracking. By merging these properties, duplex stainless steel valves offer superior durability, reliability, and suitability for demanding industrial applications.

Duplex gate valves are widely used as isolation valves in pipelines across industries such as chemical processing, petrochemical, oil and gas, water treatment, and power generation. Their simple, robust design allows for easier maintenance, extended service life, and reliable performance under challenging operating conditions.

Types of Duplex Gate Valves

Duplex gate valves come in a variety of designs to accommodate different applications and flow requirements:

Duplex Knife Gate Valves

These valves feature a thin, sharp-edged gate that can cut through slurry or viscous media, making them ideal for wastewater, pulp and paper, and mining applications. Knife gate valves are especially useful where the media contains suspended solids or fibrous materials that could clog other valve types.

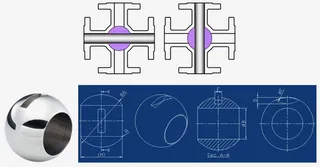

Wedge Gate Valves

Wedge gate valves are characterized by a gate that is tapered like a wedge. This design provides tight sealing and is often used in high-pressure and high-temperature services. They are especially suited for steam, oil, and gas applications where a tight shut-off is critical.

Parallel Slide Gate Valves

These valves feature a gate that slides between parallel seats, providing excellent sealing under low or moderate pressure. They are commonly used in chemical processing and other industries where thermal expansion or misalignment of the pipeline may occur.

Rising Stem Gate Valves

Rising stem designs allow the stem to visibly move up and down as the valve opens and closes. This makes it easier to monitor the valve’s position and ensures that the stem is not subjected to torsional stress during operation. Rising stem gate valves are widely used in applications where visual position indication is important.

Non-Rising Stem Gate Valves

In non-rising stem valves, the stem does not move vertically; instead, the gate moves along the stem threads. These valves are more compact and suitable for installations where vertical space is limited, such as underground pipelines or confined areas.

Each type of duplex gate valve offers distinct advantages depending on media type, pressure, temperature, and installation requirements. Selecting the right design is critical for achieving optimal performance and long-term reliability.

Actuation and Operation of Duplex Gate Valve

While many gate valves are operated manually using a handwheel, industrial automation increasingly requires actuated valves for faster, more precise, and safer operation. Our duplex stainless steel gate valves can be fitted with various actuators to meet specific operational needs.

Electric Actuators

Electric actuator gate valves provide precise, repeatable control over valve operation. They are easily integrated into automated systems and can be remotely controlled via programmable logic controllers (PLCs), SCADA systems, or distributed control systems (DCS). Electric actuators are particularly beneficial in applications where frequent operation or integration into an automated process is required.

When selecting an actuator, several standards and operational conditions must be considered:

Temperature Range: Actuators must operate reliably within the expected ambient and process temperatures.

Humidity and Environmental Protection: Actuators should be rated to resist moisture, dust, and other environmental hazards, commonly indicated by an IP (Ingress Protection) rating.

Torque and Speed: The actuator must provide sufficient torque to open and close the valve under full pressure without excessive delay or stress.

Pneumatic and Hydraulic Actuators

In addition to electric actuators, pneumatic and hydraulic actuators are often used for duplex gate valves, especially in remote locations or where high-speed operation is required. Pneumatic actuators rely on compressed air, while hydraulic actuators use pressurized fluid to move the valve stem. Both provide reliable automated control while maintaining fail-safe options when needed.

Smooth and Reliable Operation

Regardless of the actuation method, the primary goal is smooth and dependable operation. Valves must open and close without jamming, excessive torque, or leakage. To ensure this, we conduct extensive testing under real operating conditions to verify performance. Lubrication, precise machining, and careful assembly all contribute to the reliable movement of the gate and stem.

Pressure Seal Design of Duplex Gate Valve

Some duplex stainless steel gate valves utilize a pressure seal design, which is especially advantageous for high-pressure applications. Unlike conventional bonnet designs, the pressure seal bonnet relies on internal pressure to enhance sealing performance. As the internal pressure rises, it pushes the sealing surfaces together more tightly, ensuring leak-proof operation under demanding conditions.

Features of Pressure Seal Gate Valves

High-Pressure Capability: Suitable for pressures exceeding standard ratings in high-pressure steam, oil, and gas systems.

Standards Compliance: Designed and manufactured according to ASME B16.48 and other relevant standards, ensuring reliable performance and safety.

Sealing Mechanism: The pressure seal bonnet provides superior sealing, reducing maintenance requirements and extending service life.

Pressure seal valves are commonly used in critical pipelines where leakage is not an option, such as high-pressure steam lines, boiler feedwater systems, and high-pressure chemical applications.

Materials and Construction of Gate Valve

Duplex stainless steel gate valves combine the benefits of both ferritic and austenitic stainless steels:

Austenitic Stainless Steel: Provides excellent toughness, ductility, and weldability, reducing brittleness and enhancing resistance to cracking.

Ferritic Stainless Steel: Increases yield strength, resists intergranular corrosion, and improves chloride stress corrosion cracking resistance.

Our valves are constructed with high-quality duplex stainless steel, ensuring durability, corrosion resistance, and suitability for harsh chemical, petrochemical, and offshore environments. Components such as the gate, seat, stem, and body are carefully engineered to withstand mechanical stress, high pressure, and temperature fluctuations.

Testing and Certification

Before being shipped to customers, duplex stainless steel gate valves undergo rigorous testing and quality verification.

Hydrostatic Testing

Hydrostatic tests involve filling the valve with water and pressurizing it to levels above its rated working pressure. This ensures there are no leaks and that the valve body, bonnet, and seat can withstand the operating pressure safely.

Non-Destructive Testing (NDT)

NDT methods such as ultrasonic testing, magnetic particle inspection, and dye penetrant testing are employed to detect internal or surface defects. These tests are crucial for ensuring the structural integrity of the valve components.

Certifications

To provide customers with confidence in the quality and reliability of our valves, we obtain certifications such as:

CE (Conformité Européene): Demonstrates compliance with European standards.

API Monogram: Indicates compliance with American Petroleum Institute standards, widely recognized in oil and gas industries.

These certifications ensure that the valves meet international safety, reliability, and performance standards, making them suitable for global markets.

Applications of Duplex Gate Valves

Duplex stainless steel gate valves are widely used in various industries due to their strength, corrosion resistance, and reliability:

Chemical and Petrochemical Industries: For handling corrosive chemicals, acids, and hydrocarbons in pipelines.

Oil and Gas: Isolation of pipelines carrying crude oil, natural gas, refined products, and high-pressure steam.

Power Generation: In steam and cooling water systems where high-pressure and high-temperature resistance is essential.

Water Treatment: Managing water flow, chemical dosing, and high-pressure pipelines in municipal and industrial systems.

Marine and Offshore: Duplex stainless steel offers exceptional corrosion resistance in seawater applications and harsh offshore conditions.

The versatility of duplex gate valves allows them to operate effectively in extreme conditions, including high temperature, high pressure, and corrosive environments.

Maintenance and Longevity of Duplex Gate Valve

Proper maintenance ensures the long-term reliability of duplex gate valves:

Routine Inspection: Check for leaks, corrosion, and wear on seats, stems, and gates.

Lubrication: Periodically lubricate stems and mechanical components to reduce operating torque and prevent seizing.

Seal Replacement: Replace worn or damaged seats to maintain tight shutoff and prevent leakage.

Actuator Maintenance: Inspect electric, pneumatic, or hydraulic actuators regularly to ensure proper operation.

Following these procedures helps extend the service life of the valve and reduces the risk of unplanned downtime.

Conclusion

Duplex stainless steel gate valves combine the durability and corrosion resistance of duplex stainless steel with the simplicity and reliability of gate valve design. Their versatility in design—ranging from knife gate and wedge gate to rising stem and non-rising stem valves—makes them suitable for a wide array of industrial applications.

With advanced actuation options, pressure seal designs for high-pressure service, and rigorous testing and certification, these valves deliver safe, reliable, and long-lasting performance. Whether in chemical processing, oil and gas, power generation, or water treatment, duplex gate valves provide critical isolation and flow control solutions for modern industrial systems.

Send your message to this supplier

Related Articles from the Supplier

Comprehensive Guide to Pressure Seal Check Valves

- Jun 05, 2024

Comprehensive Guide to Globe Valve Maintenance

- Apr 08, 2025

Related Articles from China Manufacturers

How to Choose the Right Pump: A Comprehensive Guide

- Sep 20, 2025

Comprehensive Guide to Forging Cleaning Methods

- Dec 11, 2024

Related Products Mentioned in the Article

topper

- www.chinatopper.com

- Address: Xiamen

- Phone: 86-592-5819200

- Business Type: Trading, Industry & Trading, Manufacturer,

Supplier Website

Source: https://www.mfrsvalve.com/news/comprehensive-guide-to-duplex-gate-valves-types-materials-and-applications.html